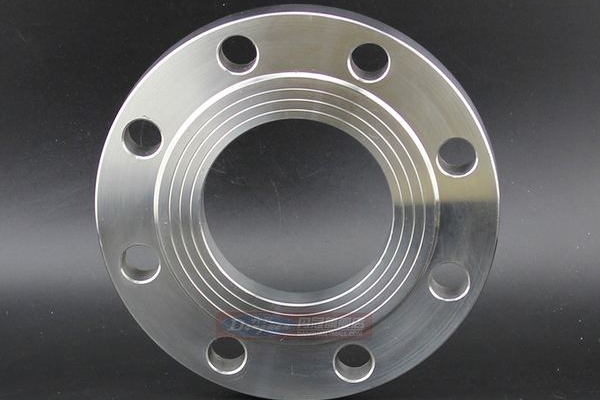

Flat welding flange'me theko ea lisebelisoa tsa lipeipi ha e arohane. Kajeno, ke tla u tsebisa li-flange tse bataletseng tsa welding bakeng sa hau ka botlalo, e le hore bareki ba be le kutloisiso e ntle ea li-flange tse bataletseng, e le hore ho be bonolo ho li reka.

A: sephara se tjheseletsa flangee bua ka aflangee amanang le setshelo kapa phala ka ho tjheseletsa fillet. Ke flange e ikemetseng. Hlahloba bohlokoaflangekapa e hlephilengflangeho ya ka botshepehi baflangeselikalikoe le karolo e otlolohileng ea pipe ka nako ea moralo. Ho na le mefuta e 'meli eaflangemehele e nang le molala le ntle le eona. Ha ho bapisoa lemolala butt welding flange, Flange e bataletseng ea welding e bonolo ka sebopeho mme e boloka lintho tse bonahalang, empa ho tiea le ho tiisa ha ho molemo joaloka molala butt welding flange. Flat welded flanges e sebelisoa haholo ho hokahanya likepe tse mahareng le tse tlase tsa khatello le liphaephe.

Ea bobeli: litšobotsi tsasephara se tjheseletsa flange: sephara se tjheseletsa flangebonyane e ka boloka sebaka le ho fokotsa boima ba 'mele, ho bohlokoa le ho feta, ho netefatsa hore lenonyeletso le ke ke la tsoa le ho ba le ts'ebetso e ntle ea ho tiisa. Ka hona, li-gaskets tsa flange li nkeloe sebaka ke mehele ea ho tiisa ho tiisa hore sebaka sa ho tiisa se lumellana le bokaholimo ba ho tiisa. Ka tsela ena, ho hlokahala khatello e nyane feela ho hatella cap ea tiiso. E le ho fokotsa ho fokotsa khatello e hlokahalang, boholo le palo ea liboutu li ka aroloa ka tsela e nepahetseng, kahoo sephetho ke sehlahisoa se secha se nyenyane ka boholo le boima bo bobebe (karolo ea 70 ho ea ho 80 lekholong e bobebe ho feta li-flange tse tloaelehileng). Ka hona,sephara se tjheseletsa flangeke boleng bo batlang bo phahamesephara se tjheseletsa flangelihlahisoa, e fokotsa boleng le sebaka, 'me e phetha karolo ea bohlokoa lits'ebetsong tsa indasteri.

Boraro:sephara se tjheseletsa flangemolao-motheo oa ho tiisa: libaka tse peli tsa ho tiisa tsa liboutu li penya gasket ea flange ebe li etsa tiiso, e leng se lebisang ho timetsong ea tiiso. E le ho boloka tiiso, matla a maholo a bolt a tlameha ho bolokoa. Ka hona, bolt e tlameha ho etsoa ka bophara. Boholo ba bolt bo hloka ho tlatsana le bophara ba linate, ho bolelang hore bophara ba bolt bo hlokahala ho theha maemo a sebelisetsoang ho tiisa linate. Leha ho le joalo, bophara le boholo ba liboutu, mokhoa o sebetsang le ts'ebetso eohle e tla hloka boholo bo boholo le boima ba 'mele. Sena se baka bothata bo itseng tikolohong ea Marine, moo boima ba 'mele kamehla e leng ntho e ka sehloohong eo motho a lokelang ho e ela hloko. 'Me, ha e le hantle, li-flange tse sephara tse cheselitsoeng ke litiiso tse sa sebetseng. 50% ea mojaro oa bolt e hlokahala hore e sebelisoe joalo ka gasket ea extrusion, athe ke 50% feela ea mojaro e hlokahalang ho boloka khatello.

Flat welded flangesli loketse liphaephe tse nang le maemo a tlase a khatello le ho feto-fetoha ha khatello e tlase, ho thothomela le ho thothomela. Li-flange tse nang le li-flat-welded li na le molemo oa hore li bonolo ho lumellana nakong ea welding le kopano 'me li batla li le theko e tlaase, kahoo li se li sebelisoa haholo.

Nako ea poso: Dec-30-2021