Tlhahlobo ea Boleng ba Li-Fittings tsa Pipe tse Forged tsa Ss - Libaka tse Fepisitsoeng - DHDZ

Tlhahlobo ea Boleng ba Lipeipi tsa Ss Forged Pipe - Libara tse Forged - DHDZ Detail:

Open Die Forgings Manufacturer in China

Libaka tse Forged

Lintho tse sebelisoang tse tloaelehileng: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV12

TS'ETSOE BARA LIPOPO

Libaka tse pota-potileng, li-Square bar, li-Flat bar le li-bar tsa Hex. All Metals e na le bokhoni ba ho theha mekoallo ho tsoa mefuteng e latelang ea alloy:

● tšepe ea motsoako

● Tšepe ea carbon

● Tšepe e sa hloekang

SEBELISA BARE MAKHONO

HLALELE

BOHLALE BOHLOKOA

MAKHELO MOTHO

Carbon, Alloy

1500 limilimithara

26000 lik'hilograma

Ts'epe e sa beng le mabali

800 limilimithara

20000 lik'hilograma

SEBELISA BARE MAKHONO

Bolelele bo phahameng ba mekoallo e pota-potileng e entsoeng le li-hex bar ke 5000 mm, ka boima bo boholo ba 20000 kgs.

Bolelele le bophara bo boholo bakeng sa mekoallo e bataletseng le mekoallo ea lisekoere ke 1500mm, ka boima bo boholo ba 26000 kgs.

Sebaka se entsoeng ka maiketsetso kapa bar e phuthoang e hlahisoa ka ho nka ingot le ho e fokotsa ho fihlela boholo, ka kakaretso, lifolete tse peli tse hanyetsanang li shoa. Litšepe tse entsoeng li atisa ho ba matla, ho ba thata le ho tšoarella ho feta liforomo tse entsoeng kapa likarolo tse entsoeng ka mochine. U ka fumana sebopeho sa lijo-thollo tse betliloeng likarolong tsohle tsa forgings, ho eketsa bokhoni ba likarolo tsa ho mamella ho loana le ho roala.

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., joalo ka moetsi ea ngolisitsoeng oa ISO ea netefalitsoeng, e tiisang hore forgings le / kapa mekoallo li ts'oana ka boleng ebile ha li na anomalies tse kotsi ho thepa ea mochini kapa thepa ea machining.

Taba:

Kereiti ea tšepe EN 1.4923 X22CrMoV12-1

Sebopeho sa Martensitic

| Sebopeho sa lik'hemik'hale % ea tšepe X22CrMoV12-1 (1.4923): EN 10302-2008 | ||||||||

| C | Si | Mn | Ni | P | S | Cr | Mo | V |

| 0.18 - 0,24 | boholo 0.5 | 0.4 - 0.9 | 0.3 - 0.8 | boholo ba 0.025 | boholo 0.015 | 11 - 12,5 | 0.8 - 1.2 | 0.25 - 0,35 |

Lisebelisoa

Powerplant, Boenjiniere ba Mechini, Ho hlahisa matla.

Likarolo tsa liphaephe, li-boilers tsa mouoane le li-turbine.

Foromo ea thomello

Round bar, Rolled Forgings Rings, Bored roundbars, X22CrMoV12-1 Forged bar

Boholo: φ58x 536L limilimithara.

Ho Forging (Hot Work) Itloaetse

Lisebelisoa li kenngoa ka sebōping 'me li futhumatsoa. Ha mocheso o fihla ho 1100 ℃, tšepe e tla etsoa. E bua ka ts'ebetso efe kapa efe ea mochini e etsang hore tšepe e oele e le 'ngoe kapa ho feta, mohlala, e bulehileng / e koetsoeng ea forging, extrusion, rolling, joalo-joalo. Nakong ea ts'ebetso ena, mocheso oa tšepe oa theoha. Ha e theohela ho 850 ℃, tšepe e tla futhumatsoa hape. Ebe u pheta mosebetsi o chesang ka mocheso oo o phahameng (1100 ℃). Tekanyo e fokolang ea karo-karolelano ea mosebetsi o chesang ho tloha ho ingot ho ea ho billet ke 3 ho isa ho 1.

Mokhoa oa Phekolo ea Mocheso

Laola thepa ea machining ea preheat ho furance ea kalafo ea mocheso. Mocheso ho isa ho 900 ℃. Tšoara mocheso ka lihora tse 6 metsotso e 5. Oli tima le ho halefa ka 640 ℃. Joale Air-pholile.

Thepa ea mochini ea X22CrMoV12-1 bareng ea fored (1.4923).

| Rm - Matla a tsitsitseng (MPa) (+QT) | 890 |

| Rp0.20.2% matla a bopaki (MPa) (+QT) | 769 |

| KV - Matla a Impact (J) (+QT) | -60 ° 139 |

| A - Min. elongation ha ho robeha (%) (+QT) | 21 |

| Brinell hardness (HBW): (+A) | 298 |

Litefiso life kapa life, ntle le tse boletsoeng ka holimo, li ka etsoa ho latela tlhoko ea moreki.

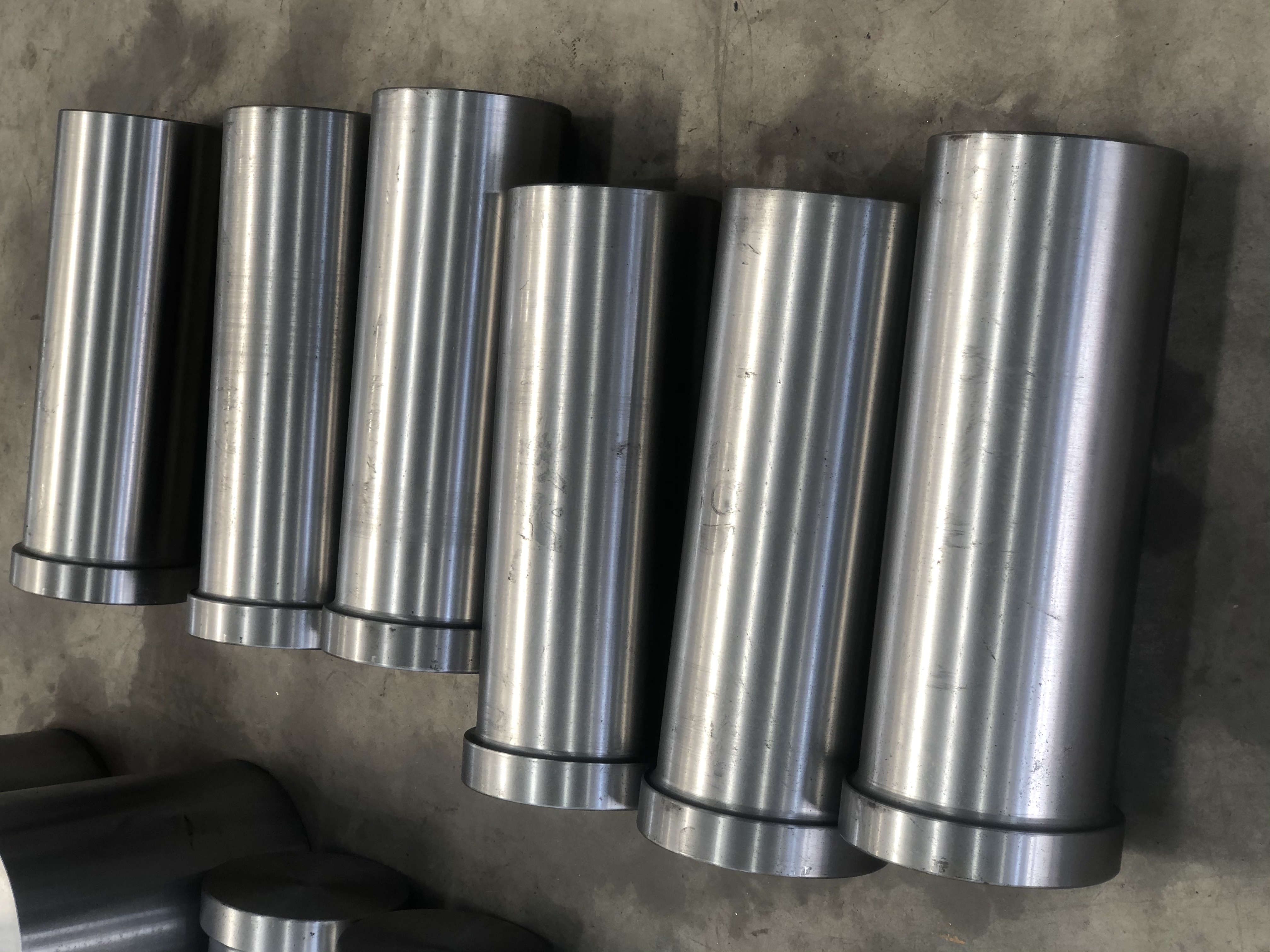

Litšoantšo tsa lintlha tsa sehlahisoa:

Tataiso e Amanang ea Sehlahisoa:

"Botšepehi, Boqapi, Bokhabane, le Ts'ebetso" e ka ba mohopolo o tsitsitseng oa khoebo ea rona ho fihlela nako e telele ea ho hlahisa hammoho le bareki bakeng sa ho lumellana le phaello e kopanetsoeng bakeng sa Tlhahlobo ea Boleng ea Ss Forged Pipe Fittings - Forged Bars - DHDZ , Sehlahisoa se tla fana ka lefats'e ka bophara, joalo ka: basebetsi ba ruileng ba Egepeta, Madagascar le basebetsi ba nang le phihlelo ba ruileng naheng ea Egepeta, Madagascar. tsebo, ka matla 'me kamehla ba hlompha bareki ba bona e le No. 1,' me ba tšepisa ho etsa sohle se matleng a bona ho fana ka tšebeletso e atlehang le ea motho ka mong bakeng sa bareki. Khampani e ela hloko ho boloka le ho nts'etsapele likamano tsa nako e telele tsa tšebelisano le bareki. Re ts'episa, joalo ka molekane oa hau ea loketseng, re tla ba le bokamoso bo khanyang mme re natefeloe ke litholoana tse khotsofatsang hammoho le uena, ka cheseho e tsitsitseng, matla a sa feleng le moea oa pele.

Khamphani e boloka mohopolo oa ts'ebetso "tsamaiso ea mahlale, boleng bo holimo le boleng bo botle, moreki ea phahameng", re 'nile ra boloka tšebelisano-'moho khoebong. Sebetsa le uena, re ikutloa re le bonolo!