Litaba tsa indasteri

-

Free forgings tlhahiso forgings lintlha tse 'maloa bakeng sa ho ela hloko

Lisebelisoa le lisebelisoa tse sebelisoang bakeng sa ho forging mahala li bonolo, li fumaneha hohle ebile li theko e tlase. Ha ho bapisoa le ho lahla letho, ho forging mahala ho felisa shrinkage cavity, shrinkage porosity, porosity le liphoso tse ling, e le hore sekheo se na le thepa e phahameng ea mochini. Forgings e bonolo ka sebopeho ebile e tenyetseha ho...Bala haholoanyane -

Lisebelisoa tsa ho forging ke life?

Ka nts'etsopele ea indasteri e boima, lisebelisoa tsa forging le tsona li fapane. Thepa ea forging e bolela lisebelisoa tsa mochini tse sebelisetsoang ho theha le ho arola ts'ebetsong ea ho qhekella. Thepa ea ho forging: 1. Forging hamore for forming 2. Mechanical press 3. Hydraulic press 4. Screw Press and forging ma...Bala haholoanyane -

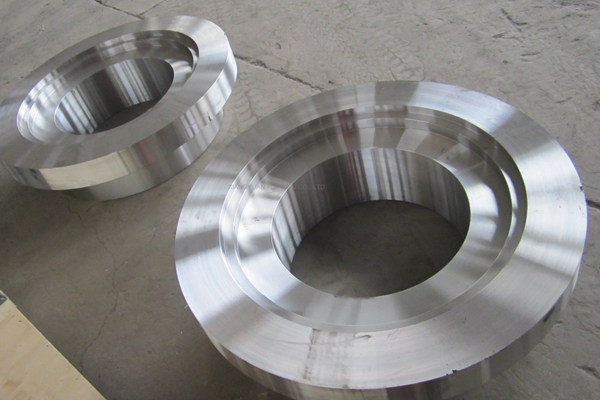

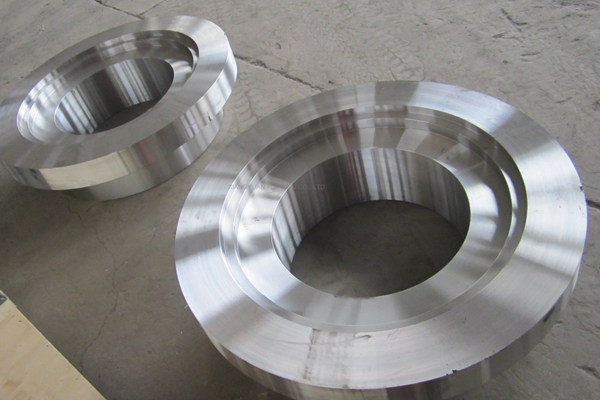

Mekhoa e fapaneng ea ho forging ea flange e kholo ea bophara

Ho na le mefuta e mengata ea ts'ebetso e kholo ea bophara ba flange, mme phapang ea theko ea flange ha e nyane. Large bophara flange forging tshebetso e tjena: 1. Tshebetso ena e haholo-holo sebelisoa bakeng sa flanges bophara bophara le segokanyimmediamentsi sa sebolokigolo e hlokehang bohareng. Leha e rekisoa, li-finis tsa mantlha ...Bala haholoanyane -

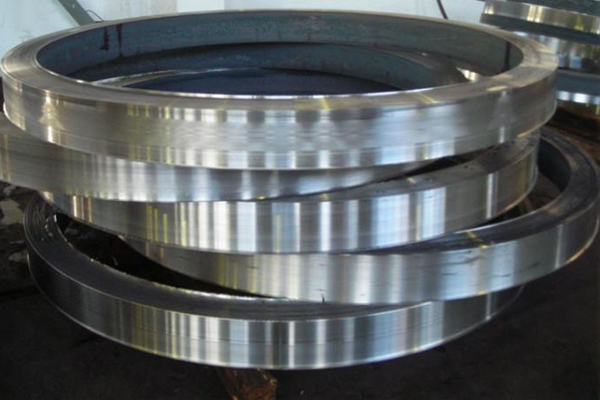

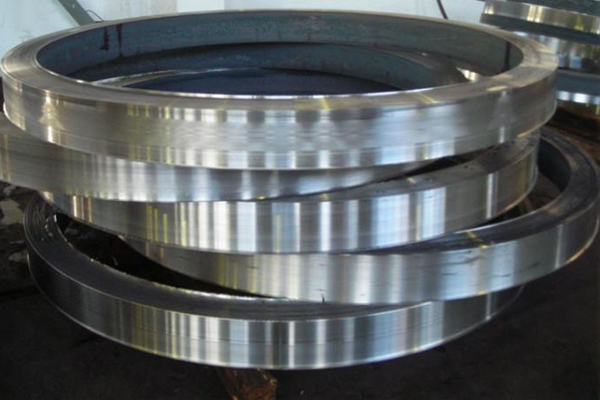

Khokahano ea Flange

Khokahano ea flange ke ho lokisa liphaephe tse peli, lisebelisoa tsa liphaephe kapa lisebelisoa ka ho latellana holim'a poleiti ea flange, 'me letlapa la flange le eketsoa pakeng tsa li-flange tse peli, tse kopantsoeng hammoho le liboutu ho phethela khokahanyo. Lisebelisoa tse ling tsa liphaephe le lisebelisoa li na le li-flange tsa tsona, tseo hape e leng li-flange c ...Bala haholoanyane -

Ke eng e lokelang ho ntlafatsoa ts'ebetsong ea tlhahiso ea likarolo tsa forging

Ts'ebelisong ea kajeno ea likarolo tsa forging, haeba taolo ea mocheso e le mpe kapa e sa tsotelleng e tla baka letoto la liphoso nakong ea tlhahiso, sena se tla fokotsa boleng ba likarolo tsa forging, e le ho felisa likotoana tsa forging tsa sekoli sena, e tlameha ho ba oa pele oa ho ntlafatsa likarolo tsa tšepe, ka ...Bala haholoanyane -

Lintlha tse susumetsang tekanyo ea tšebeliso ea flange

Tabeng ea mahoashe a tloaelehileng a li-flanges, limaraka tse fapaneng tsa tšepe le mekhoa e fapaneng ea matsoelintsoeke li na le likhato tse fapaneng tsa ho fokotsa mokhathala, joalo ka tekanyo e fokolang ea li-coil flanges tse chesang li nyane ho feta li-coil flange tse chesang. Boitlhakiso bo bontša hore cadmium plating e ka eketsa mokhathala haholo ...Bala haholoanyane -

Mekhoa ea ho futhumatsa le ho futhumatsa bakeng sa ho forging tšepe e sa hloekang

Ho ea ka lebelo le fapaneng la ho pholile, ho na le mekhoa e meraro ea ho pholile ea lisebelisoa tsa tšepe tse sa hloekang: ho pholile moeeng, lebelo la ho pholisa le potlakile; Sekhahla sa ho pholisa se lieha lehlabatheng la lime. Seboping se pholileng, lebelo la ho pholisa le lieha haholo. 1. Ho pholile moeeng, lintho tse entsoeng ka tšepe e sa hloekang ka mor'a forgin ...Bala haholoanyane -

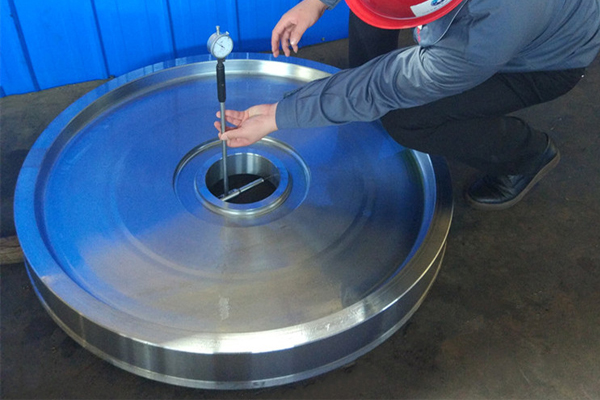

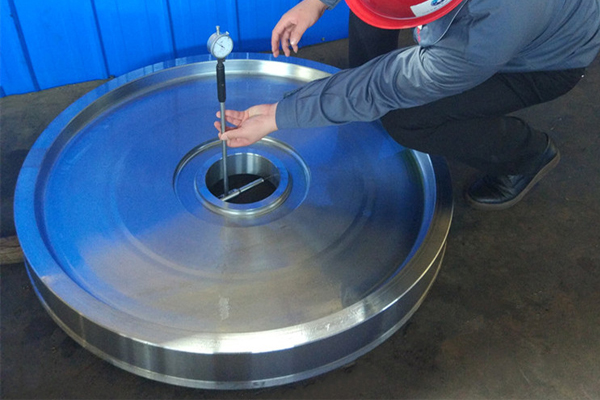

Tlhahlobo ea boleng ba ponahalo ea forgings

Tlhahlobo ea boleng ba ponahalo ka kakaretso ke tlhahlobo e sa senyeheng, hangata ka leihlo le hlobotseng kapa tlhahlobo e tlase ea khalase e khanyang, ha ho hlokahala, hape sebelisa mokhoa o sa senyeheng oa tlhahlobo. Mekhoa ea tlhahlobo ea boleng ba kahare ba forgings e boima e ka akaretsoa joalo ka: mokhatlo oa macroscopic ...Bala haholoanyane -

Ke eng eo re lokelang ho e ela hloko mabapi le polokeho nakong ea ts'ebetso ea forging?

Nakong ea ts'ebetso ea ho qhekella, mabapi le ts'ireletso, re lokela ho ela hloko: 1. tlhahiso ea ho forging e etsoa ka boemo ba tšepe e tukang (mohlala, 1250 ~ 750 ℃ mefuta e mengata ea mocheso o tlaase oa carbon steel), ka lebaka la mosebetsi o mongata oa matsoho, ho chesa ka phoso ho ka etsahala. 2. Ho futhumala ha f...Bala haholoanyane -

Forging: Mokhoa oa ho etsa forgings tse ntle?

Hona joale lisebelisoa tse sebelisoang indastering hangata li sebelisa mokhoa oa ho forging, DHDZ e fana ka lisebelisoa tsa boleng bo phahameng, joale ha ho etsoa, ho sebelisoa lisebelisoa life tse tala? Lisebelisoa tsa ho qhekella haholo-holo ke tšepe ea carbon le alloy steel, e lateloa ke aluminium, magnesium, koporo, titanium le lisebelisoa tsa tsona. Boemo ba pele ba ...Bala haholoanyane -

Ke eng eo re lokelang ho e ela hloko mabapi le polokeho nakong ea ts'ebetso ea forging?

Nakong ea ts'ebetso ea ho qhekella, mabapi le ts'ireletso, re lokela ho ela hloko: 1. tlhahiso ea ho forging e etsoa ka boemo ba tšepe e tukang (mohlala, 1250 ~ 750 ℃ mefuta e mengata ea mocheso o tlaase oa carbon steel), ka lebaka la mosebetsi o mongata oa matsoho, ho chesa ka phoso ho ka etsahala. 2. Ho futhumala ha f...Bala haholoanyane -

Na ho na le tlhoko ea ho thatafala ha shaft forgings?

Ho thatafala ha sefahleho le ho tšoana ha shaft forgings ke lintho tsa mantlha tsa litlhoko tsa tekheniki le tlhahlobo e tloaelehileng. Ho thatafala ha 'mele ho bonts'a khanyetso ea ho roala, joalo-joalo, tlhahisong, lebopo la resilience D boleng ba boima ba HSd bo sebelisetsoa ho hlalosa. Litlhoko tsa boima ba shaft forgings...Bala haholoanyane