Thethepa ea ho forginghaholo-holo tšepe ea carbon le alloy steel, e lateloa ke aluminium, magnesium, koporo, titanium le lisebelisoa tsa tsona. Boemo ba mantlha ba thepa ke bar, ingot, phofo ea tšepe le tšepe ea metsi. Karo-karolelano ea karolo ea cross-sectional ea tšepe pele le ka mor'a deformation bitsoaforging ratio. Khetho e nepahetseng eaforging ratio, mocheso o lekaneng oa ho futhumatsa le nako ea ho boloka nako, mocheso o utloahalang oa pele oa ho fereka le mocheso oa ho qetela oa ho qhekella, tekanyo e lekaneng ea deformation le lebelo la deformation li na le tšusumetso e kholo ho ntlafatsa boleng ba sehlahisoa le ho fokotsa litšenyehelo.

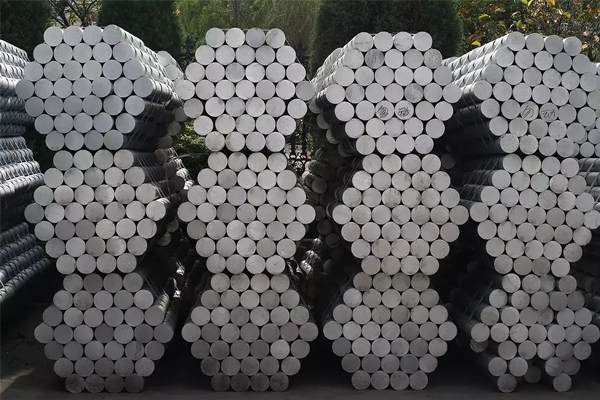

Kakaretso e nyane lemekgatlo e maharengli na le mekoallo e chitja kapa e sekoere joalo ka li-billet. Mekoallo e na le sebopeho sa lijo-thollo tse ts'oanang le thepa e ntle ea mochini, sebopeho le boholo bo nepahetseng, boleng bo botle ba bokaholimo, bo loketseng tlhahiso ea bongata. Ha feela mocheso o futhumatsang le maemo a deformation a laoloa ka mokhoa o utloahalang, o motleforgingse ka etsoa ntle lemokgoa o moholodeformation.

Ingot e sebelisoa feela bakeng samekgatlo e meholo. Ingot ke sebopeho sa as-cast se nang le likristale tse kholo tsa kholomo le litsi tse hlephileng. Ka hona, likristale tsa li-columnar li tlameha ho rojoa hore e be lijo-thollo tse ntle ka deformation e kholo ea polasetiki, 'me compaction e hlephileng e ka fumana sebopeho se setle sa tšepe le thepa ea mochini.

Powder forging e ka etsoa ka pre- made powder metallurgy preforms ka mor'a ho hatella le ho thunya tlas'a boemo bo chesang kashoe forgingntle le ho otlanya.Mekhatlophofo ke haufi le segokanyipalo sa tloaelehilengshoa forgings, e nang le thepa e ntle ea mechine le ho nepahala ho phahameng, e ka fokotsang ho itšeha ka mor'a moo. Mekhabiso ea phofo e nang le sebopeho sa kahare se ts'oanang 'me ha ho na karohano e ka sebelisoang ho etsa likere tse nyane le lisebelisoa tse ling. Leha ho le joalo, theko ea phofo e phahame haholo ho feta ea bar e tloaelehileng, kahoo ts'ebeliso ea eona tlhahisong e lekanyelitsoe. ,

Sebopeho se batloang le thepa eashoa forgingse ka fumanoa ka ho sebelisa khatello e tsitsitseng ho tšepe ea metsi e tšollang ka kamoreng ea ho shoa ho etsa hore e tiise, e khanye, e phalle, deformation ea polasetiki le sebopeho tlas'a ketso ea khatello. Metsi a tšepe a forging ke mokhoa oa ho theha lipakeng tsa ho lahla le ho fereka, haholo-holo o loketse likarolo tse thata tse nang le marako a thata ho etsoa ke batho ba tloaelehileng.shoe forging.

Ho qapalisebelisoa ho phaella ho lisebelisoa tse tloaelehileng, tse kang tse fapa-fapaneng tsa tšepe ea carbon le tšepe ea alloy, e lateloa ke aluminium, magnesium, koporo, titanium le lialloys tsa eona, mocheso o phahameng oa tšepe ea tšepe ea tšepe, nickel base superalloy, cobalt-based superalloy deformation ea alloy e boetse e SEBELISA mokhoa oa ho theha kapa oa ho roala, feela motsoako ka lebaka la sebaka sa eona se tšesaane.forgingbothata tla ba batlang e le khōlō, thepa e fapaneng futhumatsang mocheso, bulehileng forging mocheso le ho qetela forging mocheso na le ditlhoko tse tiileng.

Nako ea poso: Mar-14-2022