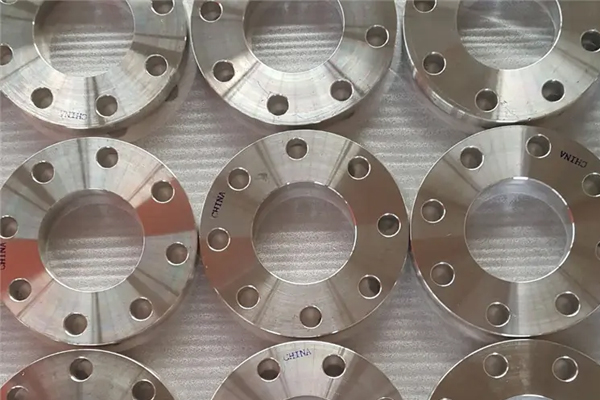

Flat welding flangeho latela thatohatsi ya haoforgingshoa motsamao, e ka aroloa ka swing rolling, swing rotaryforging, ho thetheha, ho thetheha, ho bilika, ho bilika, ho pitika, joalo-joalo. Ho etsa ka mokhoa o nepahetseng ho ka boela ha sebelisoa ho thetheha, ho phunya rotary forging le ring rolling. Roll forging le cross rolling e ka sebelisoa e le pheko ea lisebelisoa tse mosesane ho ntlafatsa ts'ebeliso ea thepa. Joalo ka forging ea mahala, forging ea rotary e entsoe ka mokhoa o itseng 'me e na le molemo oa ho theha le haeba matla a ho theha a le tlase ho boholo ba ho forging. Lisebelisoa tse rarahaneng li ka phethoa ka mokhoa o le mong kapa ho feta. Hobane ha ho na li-burr, sebaka sa ho beleha se fokotsehile mme mojaro o hlokahalang oa fokotseha.

Senaforgingmokhoa o etsa hore thepa e atolohe ho tloha haufi le flange ha e etsoa ka mochine. Hobane sebaka se pakeng tsa sebaka sa die le sebaka sa mahala se fapane, ho thata ho tiisa ho nepahala. Ka hona, ka ho laola tataiso ea motsamao oa forging die le mokhoa oa rotary forging ka k'homphieutha, lihlahisoa tse nang le sebōpeho se rarahaneng le ho nepahala ho phahameng li ka hlahisoa. E, nka e etsa. E fumanoe ka matla a tlase a ho qhekella. Li-blades turbine tsa mouoane le mefuta e meng le boholo bo boholoforgingstlhahiso.

Flat welding flange forginge ka aroloa ka bolokolohiforging, halefisa, extrusion, die forging, clotting die forging and close upsetting forging. Ka kakaretso, ho theha mocheso oa mocheso oa recrystallization ho bitsoa ho chesa ho chesa, ka mocheso oa kamore ntle le ho futhumatsa ho bitsoa ho qhoqhoa ha serame. Nengli-flange tse sepharabaqapaka mocheso o tlase, litekanyo tsaforgingsha e fetohe. Ha e entsoe ka tlase ho 700 ℃, hoo e ka bang ha ho sekala sa oxide se etsoang mme ha ho na decarburization ea holim'a metsi e etsahalang.

Flat welding flangemolao-motheo oa ho tiisa: likarolo tse peli tsa ho tiisa tsa liboutu li hatella holim'a gasket ea flange ho etsa tiiso, e ka lebisang ts'enyong ea tiiso. E le ho boloka tiiso, hoa hlokahala ho boloka matla a maholo a bolt, kahoo eketsa bolt. Liboutu tse kholo li lokela ho ts'oana le linate tse kholo. Sena se bolela hore o tla hloka liboutu tse kholoanyane tsa bophara ho theha maemo a ho tiisa nate.

Hlokomela bakeng sasephara se tjheseletsa flange

1. Letlapa la tšepe le sebelisetsoang ho etsali-flange tse sepharae etsoa le ho sebelisoa ka tlhahlobo ea ultrasonic ntle le delamination, e le ho tseba mathata a boleng bo botle le ts'ebetso, 'me e etsoa le ho lekoa ho latela litlhoko tse khethehileng tsa boleng, poleiti ea tšepe ha e na mathata a boleng.

2. Tšepe e khaoloa ka lihlopha ho latela tataiso ea ho roala, ebe e kobeha le butt e kenngoa ka mehele, e etsa sebaka se chitja holim'a tšepe. Moqomo. Ha ho etsoa li-flange tse nang le li-flange tse nang le sephara, letlapa la tšepe ha lea lokela ho etsoa ka ho toba molaleng oa molala, empa ho e-na le hoo le etsoa le ho sebelisoa ka mokhoa o itseng.

Nako ea poso: Jun-13-2022