LH-VOC-RTO

Lintlha tsa sehlahisoa

Sepheo le bophara

RTOe loketse bakeng sa phekolo ea khase ea litšila tse entsoeng ka lihlahisoa tsa likoloi le tsa mechine, mehala ea ho roala le likamore tsa ho omisa; tlhahiso ea elektronike, boto ea potoloho e hatisitsoeng (PCB) phekolo ea khase ea litšila; tlhahiso ea motlakase, terata e entsoeng ka enameled kalafo ea khase ea litšila; indasteri e bobebe, sekhomaretsi sa ho etsa lieta sekhomaretsi sa organic litšila kalafo ea khase; khatiso le mebala khatiso manyolo litšila pheko ea khase.

E loketse bakeng sa phekolo ea khase ea litšila tse phelang indastering ea tšepe ea metallurgic le tlhahiso ea carbon electrode; phekolo ea khase ea litšila tse phelang indastering ea lik'hemik'hale le mokhoa oa ho kopanya lik'hemik'hale (ABS synthesis).

E loketse libaka tse fapaneng moo ho hlahisoang khase ea litšila ea tlhaho joalo ka khase ea litšila ea manyolo ka har'a tlhoekiso ea peterole le ts'ebetsong ea lik'hemik'hale.

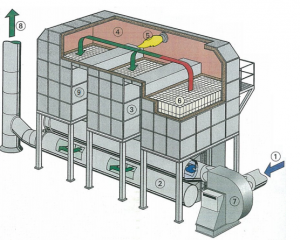

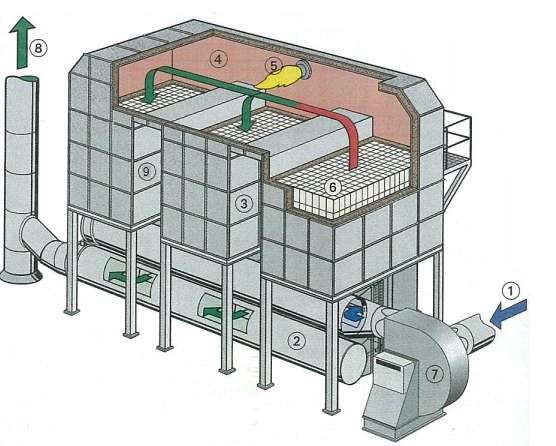

Molao-motheo oa ts'ebetso

Pele ho phekoloa ha khase ea ho qeta 'mele oa sebōpi, kamore ea mollo le bethe e nchafatsang li chesoa pele; ka mor'a hore preheating e phethoe, mohloli oa khase ea ho qeta o kopantsoe le thepa. Khase ea litšila ea lintho tse phelang ke mocheso oa pele o fapanyetsanoang ke 'mele oa ceramic o futhumatsang mocheso oa 1 tlas'a ketso ea fan e tšehetsang. Khase ea litšila e kena sebakeng sa ho futhumatsa ka mor'a ho eketseha ha mocheso. Sebakeng sa ho futhumatsa, khase ea ho qeta e futhumala ka lekhetlo la bobeli. Ka mor'a hore mocheso oa karabelo o hlokehe, o kena ka kamoreng ea catalytic bakeng sa ho itšoara, o hlahisa carbon dioxide le metsi 'me o ntša le ho ntša matla a mocheso; khase e hloekileng e hloekisitsoeng e feta ka har'a 'mele oa ceramic oa polokelo ea mocheso oa 2 bakeng sa polokelo ea mocheso 'me e ntšoa ke fan. Ha mocheso o fumanoa ke molamu oa ho lekanya mocheso sebakeng sa ho kena ha fan ea ho qeta mocheso 'me mocheso o behiloeng o fihletsoe, valve e tlosoa ho tloha polokelong ea mocheso ea 'mele oa ceramic 2 ho ea khase ea ho tsoa,' me setopo sa polokelo ea mocheso 1 se lokolloa, 'me potoloho e pheta.

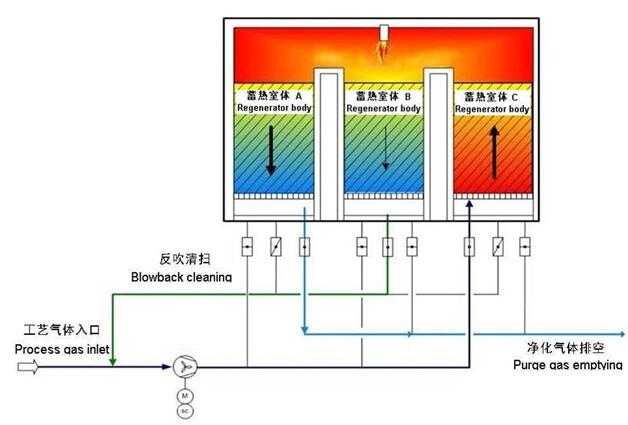

3-Chamber RTO process flow chart

Chate ea ho phalla ha mokhoa oa Rotary RTO

Litšobotsi tsa theknoloji

1. E amohela theknoloji e 'ngoe ea ho fetola mocheso oa preheating le ho boloka mocheso ho etsa hore e be le ts'ebetso e phahameng ea phapanyetsano ea mocheso, ho sebetsa hantle ho feta 90-95% kapa ho feta,' me ts'ebetso ea ho boloka matla e tsoteha.

2. Mocheso o sebelisetsoa ho futhumatsa, o ka hlokomelang ts'ebetso ea ho lokisa ka mokhoa o lekanang oa ts'ebetso ea matla a phahameng le a tlaase, 'me o na le mesebetsi ea ho hloekisa pele, tšireletso ea mollo, alamo ea mocheso o feteletseng le phepelo ea oli e ikemetseng e khaotsoe; ts'ebetso e bolokehile, e ka tšeptjoa, e sebetsa hantle ebile e tšoarella.

3. E amohela taolo ea boiketsetso ea microcomputer le taolo ea mocheso oa lintlha tse ngata ho hlokomela liketso tse ngata tsa ts'ireletso, ho khutlisa tlhaiso-leseling ea ts'ebetso, le tlhaiso-leseling ea tlhaiso-leseling, e le hore sistimi e ka sebetsa ka mokhoa o sireletsehileng, ka botsitso le ka ts'epo.

4. Sephahla se nka mochine oa phetisetso ea pneumatic, e leng ntho e utloahalang le e potlakileng ho feta mokhoa oa ho fetisa motlakase.

5. Khase e ntšoang ka har'a mochine oa ho chesoa e na le lintho tse ngata tse fokolang: VOC<120mg/Nm³, CO<100 mg/Nm³, NOx<100 mg/Nm³.

Re khetha lisebelisoa tse nepahetseng joang?

| Litlhaloso le Mehlala | LH-VOC-RTO- 3000 | LH-VOC-RTO- 5000 | LH-VOC-RTO- 10000 | LH-VOC-RTO- 15000 | LH-VOC-RTO- 20000 | LH-VOC-RTO- 30000 | LH-VOC-RTO- 40000 | LH-VOC-RTO- 50000 | LH-VOC-RTO- 60000 | |

| Kalafo phallo ea moea m³/h | 3000 | 5000 | 10000 | 15000 | 20000 | 30000 | 40000 | 50000 | 60000 | |

| Khase ea tlhaho ho tsepamisa maikutlo | 100~8000mg/m³(motsoako) | |||||||||

| Mofuta oa Khase ea tlhaho | Triphenyl , joala, ether, aldehyde, phenol, ketone, ester le VOC tse ling; khase e mpe, joalo-joalo. | |||||||||

| Mocheso oa regenerator ho hlaphoheloa hantle | ≥95% | |||||||||

| Tlhoekiso e sebetsang hantle | ≥98-99% | |||||||||

| Boholo ba lisebelisoa | Bolelele(mm) | 6280 | 6280 | 8375 | 9690 | 10600 | 14265 | 15180 | 16095 | 17925 |

| Bophara(mm) | 1550 | 1880 | 2135 | 2440 | 2745 | 2745 | 3050 | 3660 | 3660 | |

| Bophahamo(mm) | 5000 | 5600 | 5600 | 6000 | 6500 | 7000 | 7000 | 7500 | 7500 | |

| Boholo ba tlhahiso ea mocheso oa mocheso oa burner(kcal/h) | 14×10⁴ | 25×10⁴ | 25×10⁴ | 60×10⁴ | 100×10⁴ | 100×10⁴ | 120×10⁴ | 200×10⁴ | 200×10⁴ | |

| Tšebeliso ea mafura | qalo | Boholo tlhahiso ea tjheseletsa | ||||||||

| ts'ebetso e tloaelehileng | E ikemiseditse ho ya ka kgase ya kgase, ha mahloriso a le ka hodimo ho 1600 ~ 2000mg/Nm³, RTO e ka boloka mollo o itlelang feela. | |||||||||

| Khatello ea bethe e theoha | ≤3500 Pa | |||||||||

Hlokomela:

1. Litlhaloso tse ling tsa bophahamo ba moea li ka etsoa ka thoko.

2. Haeba ho na le tlhokahalo ea mafura, ka kopo bolela ha u reka.

3. Sebelisa likamore tse peli kapa tse tharo kapa RTO ea rotary ho latela matsete a basebelisi le katleho ea tlhoekiso ea lisebelisoa.

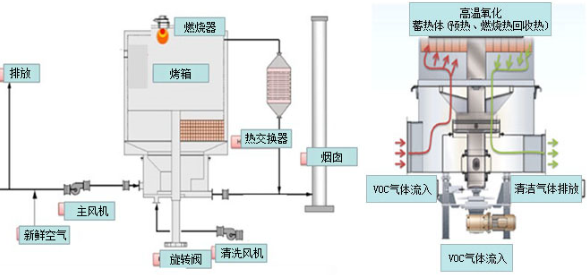

Nyeoe ea morero

Khase ea mouoane e tsoetsoeng ke k'hamphani e etsang likarolo tsa likoloi tsa X ke 50,000 m³/h, 'me khatello ea maikutlo e ka ba 200-300mg/m³. Bakeng sa mofuta ona oa khase ea litšila e nang le boleng bo phahameng le e tlase, Rōna DHDZ le LH re sebelisa filtration + UV pretreatment + concentrated drum + rotating RTO technology ho tšoaneleha khase ea litšila! Khase ea litšila ea workshop e bokelloa ka liphaephe bakeng sa ho tlosa lerōle le ho sefa, ebe e phekoloa pele, ebe e fetisetsoa ho semathi Ka mor'a hore adsorption, e tsoe ho fihlela ho tloaelehileng.

Filtration + pretreatment + drum e potolohang + ts'ebetso ea kalafo ea khase ea litšila ea RTO e na le litšobotsi tsa ts'ebetso e tsitsitseng le e ts'epahalang le boemo bo phahameng ba boits'oaro. Ka mor'a hore thepa e buletsoe, e ka ba e sa lebelloang. 'Me thepa eohle e hokahane le tsamaiso ea taolo ea line ea tlhahiso ea workshop ho fetola ka mokhoa o bonolo nako ea ho qala le ea ho emisa, ntle le ts'ebetso e eketsehileng ea matsoho. Ke mokhoa o ratoang oa ho phekola khase e tsoang ho lik'hamphani tse fafatsang!