Mokhoa o Molemo oa ho Etsa Mehala - Li-tubes tse Forged - DHDZ

Mehala e Ntle ea Lichelete - Li-tubes tse Forged - DHDZ Detail:

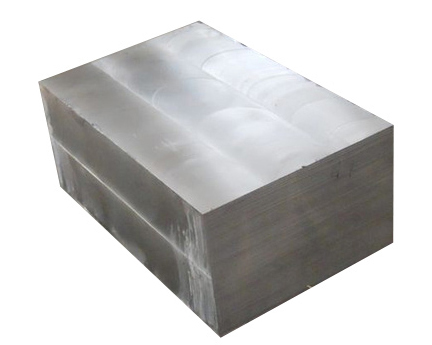

Open Die Forgings Manufacturer in China

MOKHOA OA FORGED/ HOLLOW TUBE /FORGED SEAMLESS TUBE

| Max. OD | Max. Bolelele | Max. Boima ba 'mele |

| 1000mm | 3000mm | 12 000 Kgs |

DHDZ e etsa lerako le nang le sekoti, le sekoti le matsoho a matsoho ka mefuta e fapaneng ea litlhophiso ho latela litlhoko tsa bareki. Likoti tse se nang seamless li loketse lits'ebetso tsa khatello e phahameng ea maikutlo le tikoloho e thata ka lebaka la ho tšoarella ha tsona, matla le ho hanyetsa kutu. Likoti li ka hlahisoa eseng feela ka sebopeho se otlolohileng sa cylindrical, empa ka mefuta e sa lekanyetsoang ea li-OD le li-ID, ho kenyelletsa le li-tapers.

Ntle le moo, DHDZ e fana ka ts'ebetso eohle e tlase ho kenyelletsa kalafo ea mocheso, mochini oa mochini le tlhahlobo e sa senyeheng, ha e kopa. Ikopanye le rona kajeno ka litlhaloso tsa hau hantle, sehlopha sa rona se tla sebetsa le uena ho sebelisa bokhoni ba rona ho fokotsa litšila le ho fokotsa ho se sebetse hantle ha ts'ebetso.

Lintho tse sebelisoang tse tloaelehileng: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV |EN 1.4201 |42CrMo4

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., joalo ka moetsi ea ngolisitsoeng oa ISO ea netefalitsoeng, e tiisang hore forgings le / kapa mekoallo li ts'oana ka boleng ebile ha li na anomalies tse kotsi ho thepa ea mochini kapa thepa ea machining.

Tlhaloso ea Sehlahisoa

Re bahlahisi ba ka sehloohong ba AISI 4140, SAE 4140 liphaephe tse forged/forging, AISI 4140, SAE 4140 Forging/forging tubes, AISI 4140, SAE 4140 Forged/forging bars, 42Crmo4 Forged/forging pipes,42C Forging tubes,42C 1.7225 liphaephe tse ferekantsoeng, 1.7225 liphaephe tse betliloeng, 1.7225 fektheri ea lifeme tse ferekaneng/tse qhekellang tse tsoang China.

Re ne re ka hlahisa AISI 4140, SAE 4140 liphaephe tsa forged/forging, AISI 4140, SAE 4140 Forging/forging tubes, AISI 4140, SAE 4140 Forged/forging bars, 42Crmo4 Forged/forging pipes, 42Cr4forging2forging/tubermoging4 mekoallo e sekoti, 1.7225 lipeipi tsa forged/forging, 1.7225 Forged/forging tubes, 1.7225 Forged/forging bars tse nang le bophara ba ho tloha 100MM ho isa 1200MM, le lenth ho tloha 100MM ho isa 10000MM, boima ba ho tloha 100K0GS ho isa ho 10K0GS

Re ka etsa mochini o thata kapa oa ho qetela oa AISI 4140, SAE 4140 lipeipi tsa forged/forging, AISI 4140, SAE 4140 Forging/forging tubes, AISI 4140, SAE 4140 Forged/ forging hollow bar, 42Crmo4 Forged/forging/forging pipes,4 42Crmo4 li-bar tse se nang letho, 1.7225 liphaephe tse betliloeng, tse 1.7225, 1.7225 1.7225 litšepe tse se nang letho ho latela setšoantšo sa bareki.

Phekolo ea mocheso:Tloaelehile / E timisitsoe / E timiloe

Kalafo ea Bokaholimo:ho penta, ho pola, ho bentša, oxide e ntšo, oli e hlakileng e khahlanong le mafome

Taolo ea boleng:UT, MT, RT, PT, tlhahlobo ea sebopeho sa lik'hemik'hale, tlhahlobo ea thepa ea mochini, jj.

Tlhahlobo

1. Setifikeiti sa thepa e tala(material chemical composition)

2. Tlaleho ea pampiri ea phekolo ea mocheso

3. Tlaleho ea tlhahlobo ea tekanyo

4. Tlaleho ea tlhahlobo ea UT

Boemo ba thomello

Hot forged +Rough machined (bokaholimo bo botšo ka mor'a Q /T)+ E Fetotsoe

Molemo oa Tlholisano

Taolo ea boleng le taolo ea ts'ebetso eohle ea lihlahisoa, ho kenyelletsa le ho qhibilihisa ingot, forging, kalafo ea mocheso, machining le tlhahlobo e tiileng ea ho qetela pele ho pepa.

Boleng bo botle ba sehlahisoa le tšebeletso, theko ea tlholisano, phano ea "ka nako".

Taba:Steel Grade AISI 4140 Alloy Steel

Lintho Tsa 'Mele

| Thepa | Metric | Mperial |

| Botenya | 7.85 g/cm3 | 0.284 lb/in³ |

| Sebaka se qhibilihang | 1432°C | 2610°F |

AISI 4140 Alloy Steel Specifications le Equivalents

| AISI 4130 | C | Mn | Si | P | S | Cr | Mo | Ni | Cu | Mo |

| 0.38 - 0,43 | 0.75 - 1.00 | 0.15 - 0,35 | 0.030 boholo | 0.040 boholo | 0.80-1.10 | 0.15-0,25 |

0.25 max | 0.35 max | 0.15-0,25 |

| ASTM A29/A29M | DIN17350 | BS970 | JIS G4105 | GB/T 3077 | AS 1444 | ISO 683/18 |

| AISI 4140 | 1.7225/ | 42CrMo4 | SCM440 | 42CrMo | 4140 | 25CrMo4 |

| 42CrMo4 |

Forging (Hot Work ) Itloaetse , Phekolo ea Mocheso Proc

| Ho qapa | 1093-1205 ℃ |

| Annealing | 778-843 ℃ sebōpi se pholileng |

| Ho halefisa | 399-649 ℃ |

| Ho tloaeleha | 871-898 ℃ moea o pholileng |

| Austenize | 815-843 ℃ ho tima metsi |

| Fokotsa Khatello | 552-663 ℃ |

| Ho tima | 552-663 ℃ |

| Rm - Matla a tsitsitseng (MPa) (Q +T) | ≥930 |

| Rp0.2 0.2% matla a bopaki (MPa) (Q +T) | ≥785 |

| KV - Matla a Impact (J) (Q +T) | +20°? |

| A - Min. elongation at fracture (%)(Q +T) | ≥12 |

| Z - Phokotso ea karolo ea sefapano ho robeha (%)(N+Q +T) | ≥50 |

| Brinell hardness (HBW): (Q +T) | ≤229HB |

TLHAHISOLESELING E 'NGOE

KOPO LEKHOTSO

KAPA LETSA: 86-21-52859349

Litšoantšo tsa lintlha tsa sehlahisoa:

Tataiso e Amanang ea Sehlahisoa:

Hape re fana ka tharollo ea ho fumana thepa le ho kopanya lifofane. Hona joale re na le setsi sa rona sa tlhahiso le sebaka sa ho fumana mosebetsi. Re ka u fa hoo e batlang e le mofuta o mong le o mong oa thepa e amanang le mefuta e fapaneng ea thepa ea rona bakeng sa Good Quality Ring Forging - Forged Tubes - DHDZ , Sehlahisoa se tla fana ka lefats'e ka bophara, joalo ka: Seychelles, New Delhi, Manchester, Thepa e ngata e lumellana ka botlalo le litataiso tsa machaba le lits'ebeletso tsa rona tsa pele tsa phano eo u tla ba le eona sebakeng sefe kapa sefe. Mme hobane Kayo e sebetsana le mefuta eohle ea lisebelisoa tsa ts'ireletso, bareki ba rona ha ba tlameha ho senya nako ho ea mabenkeleng.

Joaloka setsebi sa indasteri ena, re ka re k'hamphani e ka ba moetapele indastering, ba khetha ho nepahetse.