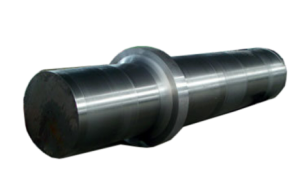

Shaft e entsoeng

Open Die Forgings Manufacturer in China

SHAFT E FEDHILENG / MOHATO OA MOHATO/ SPINDLE / AXLE SHAFT

Libaka tsa kopo tsa forgings shaft li

Li-shaft forgings (likarolo tsa mochini) Li-shaft forgings ke lintho tse cylindrical tse aparoang bohareng ba bering kapa bohareng ba lebili kapa bohareng ba gear, empa tse seng kae li na le lisekoere. Shaft ke karolo ea mochini e ts'ehetsang karolo e potolohang mme e potoloha ka eona ho fetisa motsamao, torque kapa nako ea ho kobeha. Ka kakaretso, ke sebōpeho sa molamu oa tšepe, 'me karolo ka' ngoe e ka ba le bophara bo fapaneng. Likarolo tsa mochine o etsang motsamao oa ho bolaea li behiloe holim'a shaft. Sechaena lebitso la shaft forging mofuta oa shaft, mandrel, drive shaft material 1, carbon steel 35, 45, 50 le tse ling tsa boleng bo phahameng carbon structural tšepe ka lebaka la thepa ea eona e phahameng comprehensive mechine, ditshebediso tse ngata, eo 45 tšepe sebelisoa ka ho fetisisa. E le ho ntlafatsa thepa ea eona ea mechine, ho tloaelehile kapa ho tima le ho futhumatsa ho lokela ho etsoa. Bakeng sa li-shafts tsa sebopeho tse seng tsa bohlokoa kapa tse nang le matla a tlase, litšepe tsa sebopeho sa carbon tse kang Q235 le Q275 li ka sebelisoa. 2, tšepe ea alloy Alloy steel e na le thepa e phahameng ea mochini, empa theko e theko e phahameng haholo, e sebelisoa haholo bakeng sa shafts e nang le litlhoko tse ikhethang. Ka mohlala, li-shafts tse lebelo le phahameng tse sebelisang li-sliding bearings, tse atisang ho sebelisoa litšepe tse nang le carbon alloy structural tse kang 20Cr le 20CrMnTi, li ka ntlafatsa ho hanyetsa ha koranta ka mor'a ho tsuba le ho tima; rotor shaft ea jenereithara ea turbo e sebetsa tlas'a mocheso o phahameng, lebelo le phahameng le maemo a boima bo boima. Ka lisebelisoa tse ntle tsa mocheso o phahameng, litšepe tsa sebopeho sa alloy joalo ka 40CrNi le 38CrMoAlA hangata li sebelisoa. Sekheo sa shaft se khethoa bakeng sa ho forging, se lateloa ke tšepe e chitja; bakeng sa mehaho e meholo kapa e rarahaneng, tšepe e entsoeng ka tšepe kapa tšepe ea ductile e ka nkoa. Mohlala, ho etsoa ha crankshaft le camshaft ho tsoa ho tšepe ea ductile ho na le melemo ea theko e tlase, ho monya hantle ho sisinyeha, kutlo e tlase ea khatello ea maikutlo le matla a matle. Mohlala oa mochini oa shaft ke beam, eo hangata e potolohang, kahoo khatello ea eona hangata ke potoloho ea symmetric. Mekhoa e ka bang teng ea ho hloleha e kenyelletsa ho robeha ha mokhathala, ho robeha ho feteletseng, le deformation e feteletseng ea elastic. Likarolo tse ling tse nang le li-hubs li atisa ho kenngoa holim'a shaft, kahoo li-shafts tse ngata li lokela ho etsoa li-shafts tse nang le mekhoa e mengata ea machining. Tlhophiso ea Sebopeho Moralo oa Sebopeho Moralo oa sebopeho sa shaft ke mohato oa bohlokoa oa ho khetholla sebopeho se utloahalang le boholo ba sebopeho sa shaft. E na le mofuta, boholo le boemo ba karolo e behiloeng holim'a shaft, tsela eo karolo e tsitsitseng ka eona, sebopeho, tataiso, boholo le kabo ea mojaro, mofuta le boholo ba ho jara, sekheo sa shaft, mokhoa oa ho etsa le ho kopanya, ho kenya le ho tsamaisa, shaft The deformation le lintlha tse ling li amana. Moqapi a ka etsa moralo ho latela litlhoko tse khethehileng tsa shaft. Haeba ho hlokahala, merero e mengata e ka bapisoa le ho khetha moralo o motle ka ho fetisisa.

Lintlha tse latelang ke melao-motheo ea moralo oa shaft ka kakaretso

1. Boloka lisebelisoa, fokotsa boima ba 'mele,' me u sebelise sebōpeho se lekanang le matla. Sebopeho sa coefficient ea karolo e kholo kapa e kholo ea likarolo tse fapaneng.

2, ho bonolo ho e beha ka nepo, ho tsitsisa, ho bokella, ho qhaqholla le ho lokisa likarolo tsa shaft.

3. Sebelisa mekhoa e fapaneng ea meralo ho fokotsa khatello ea maikutlo le ho ntlafatsa matla.

4. Ho bonolo ho etsa le ho netefatsa ho nepahala.

Ho hlophisoa ha lithupa Li-shaft tse tloaelehileng li ka aroloa ka li-crankshafts, li-shaft tse otlolohileng, li-shaft tse tenyetsehang, li-shaft tse tiileng, li-hollow shafts, li-shafts tse thata, le li-flexible shafts (li-flexible shafts) ho itšetlehile ka sebōpeho sa sebopeho sa sefate.

Shaft e otlolohileng e ka aroloa ka ho eketsehileng

1 shaft, e tlas'a nako ea ho kobeha le torque, 'me ke eona shaft e atileng haholo mochining, joalo ka li-shafts tse fokotsang lebelo le fapaneng.

2 mandrel, e sebelisetsoang ho tšehetsa likarolo tse potolohang feela ho jara nako ea ho khumama ntle le ho fetisetsa torque, ho potoloha ha mandrel, joalo ka ense ea koloi ea terene, joalo-joalo, mandrel a mang ha a potoloha, joalo ka molamu o tšehetsang pulley.

3 Shaft ea phetisetso, e sebelisoang haholo ho fetisa torque ntle le nako e kobehang, joalo ka axis e telele ea optical mochining o tsamaeang oa crane, shaft ea koloi, jj.

Thepa ea shaft haholo-holo ke tšepe ea carbon kapa alloy steel, le tšepe ea ductile kapa alloy cast iron le eona e ka sebelisoa. Bokhoni ba ho sebetsa ba shaft ka kakaretso bo itšetlehile ka matla le ho satalla, 'me lebelo le phahameng le itšetlehile ka botsitso ba ho sisinyeha. Kopo ea Kopo Ho satalla ha torsional ho satalla ha shaft ho baloa e le palo ea torsional deformation ea shaft nakong ea ts'ebetso, e lekantsoeng ho latela angle ea torsion ka mithara ea bolelele ba shaft. The torsional deformation ea shaft e lokela ho ama ts'ebetso le ts'ebetso e nepahetseng ea mochini. Ka mohlala, haeba torsion angle ea camshaft ea enjene e tukang ka hare e le khōlō haholo, e tla ama nako e nepahetseng ea ho bula le ho koala ha valve; angle ea torsion ea shaft ea phetisetso ea mochini oa motsamao oa gantry crane e tla ama synchronism ea lebili la ho khanna; Ho hlokahala ho satalla ho hoholo ha li-shafts tse kotsing ea ho sisinyeha ha torsional le shafts tsamaisong ea ts'ebetso.

Litlhoko tsa tekheniki 1. Ho nepahala ha mochini

1) Ho nepahala ha tekanyo Ho nepahala ha likarolo tsa shaft haholo-holo ho bolela bophara le ho nepahala ha sekhahla sa shaft le ho nepahala ha tekanyo ea bolelele ba shaft. Ho ea ka litlhoko tsa ts'ebeliso, ho nepahala ha bophara ba koranta ea mantlha hangata ke IT6-IT9, mme koranta e nepahetseng le eona e fihla ho IT5. Bolelele ba shaft hangata bo hlalosoa e le boholo ba lebitso. Bakeng sa bolelele bo bong le bo bong ba shaft e hatelitsoeng, mamello e ka fanoa ho latela litlhoko tsa tšebeliso.

2) Ho nepahala ha Geometri Likarolo tsa Shaft hangata li tšehetsoa ke likoranta tse peli. Likoranta tsena tse peli li bitsoa limakasine tsa tšehetso hape ke litšupiso tsa kopano bakeng sa shaft. Ntle le ho nepahala ha dimensional, ho nepahala ha geometri (ho pota-pota, cylindricity) ea koranta e tšehetsang hangata ho hlokahala. Bakeng sa likoranta tsa ho nepahala ka kakaretso, phoso ea geometry e lokela ho lekanyetsoa ho mamello ea bophara. Ha litlhoko li phahame, litekanyetso tsa mamello tse lumelletsoeng li lokela ho boleloa ho setšoantšo sa karolo.

3) Ho nepahala ha maemo Ho kopanngoa pakeng tsa likoranta tsa ho nyalana (likoranta tsa litho tse kopaneng tsa koloi) likarolong tsa shaft tse amanang le limakasine tsa tšehetso ke tlhokahalo e tloaelehileng bakeng sa ho nepahala ha tsona ka bobeli. Ka kakaretso, shaft ka mokhoa o nepahetseng o tloaelehileng, ho nepahala ho ts'oanang mabapi le ho phalla ha radial ea koranta ea tšehetso hangata ke 0.01-0.03 mm, 'me shaft e nepahetseng haholo ke 0.001-0.005 mm. Ho phaella moo, ho nepahala ha maemo a mabeli ho boetse ho na le coaxiality ea libaka tse ka hare le tsa ka ntle tsa cylindrical, perpendicularity ea lifahleho tsa ho qetela tse behiloeng axially le mohala oa axial, joalo-joalo. 2, bokaholimo ba bokaholimo Ho ea ka ho nepahala ha mochini, lebelo la ts'ebetso, litlhoko tsa bokaholimo ba likarolo tsa shaft le tsona li fapane. Ka kakaretso, bokaholimo ba Ra ea koranta e tšehetsang ke 0.63-0.16 μm; bokaholimo Ra ea koranta e tšoanang ke 2.5-0.63 μ m.

Theknoloji ea ts'ebetso ea 1, khetho ea likarolo tsa shaft ea likarolo tsa shaft, haholo-holo e ipapisitse le matla, ho satalla, ho hanyetsa le mokhoa oa tlhahiso ea shaft, le ho loanela moruo.

Lintho tse sebelisoang tse tloaelehileng: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV| EN 1.4201 |42CrMo4

RETS'ELISITSOE SHATE

Large forged Shaft up to 30 T.. Forging ring tolerance ka tlwaelo -0/+3mm ho fihla ho +10mm ho itshetlehile ka boholo.

●All Metals e na le bokhoni ba ho qhekella ho hlahisa selikalikoe sa maiketsetso ho tsoa mefuteng e latelang ea alloy:

● tšepe ea motsoako

●Tšepe ea khabone

●Tšepe e sa hloekang

MAKHONO E FUMANE

Lintho tse bonahalang

MAX DIAMETER

MAKHELO MOTHO

Carbon, tšepe ea motsoako

1000mm

20000 lik'hilograma

Ts'epe e sa beng le mabali

800 limilimithara

15000 lik'hilograma

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., joalo ka moetsi ea ngolisitsoeng oa ISO ea netefalitsoeng, o tiisa hore liforomo le / kapa mekoallo li ts'oana ka boleng ebile ha li na anomalies tse kotsi ho thepa ea mochini kapa thepa ea machining.

Taba:

Kereiti ea tšepeBS EN 42CrMo4

Litlhaloso tsa BS EN 42CrMo4 Alloy Steel Litlhaloso le Litšoaneleho

| 42CrMo4/1.7225 | C | Mn | Si | P | S | Cr | Mo |

| 0.38-0,45 | 0.60-0.90 | 0.40 boholo | 0.035 boholo | 0.035 boholo | 0.90-1.20 | 0.15-0.30 |

| BS EN 10250 | Boitsebiso No. | DIN | ASTM A29 | JIS G4105 | BS 970-3-1991 | BS 970-1955 | AS 1444 | HLOMPHO | GB |

| 42CrMo4 | 1.7225 | 38HM | 4140 | SCM440 | 708M40 | EN19A | 4140 | 42CD4 | 42CrMo |

Sehlopha sa tšepe 42CrMo4

Lisebelisoa

Libaka tse ling tse tloaelehileng tsa ts'ebeliso ea EN 1.4021

Likarolo tsa pompo le li-valve, Shafting, Spindels, lithupa tsa piston, Fittings, Stirrers, Bolts, Nuts

TS EN 1.4021 selikalikoe se entsoeng ka tšepe, mehala ea tšepe e se nang tšepe bakeng sa selikalikoe sa Slewing

Boholo: φ840 x L4050mm

Ho Forging (Mosebetsi o Chesang) Itloaetse , Mokhoa oa Phekolo ea Mocheso

| Ho qapa | 1093-1205 ℃ |

| Anealing | 778-843 ℃ sebōpi se pholileng |

| Ho halefisa | 399-649 ℃ |

| Ho tloaeleha | 871-898 ℃ moea o pholileng |

| Austenize | 815-843 ℃ ho tima metsi |

| Fokotsa Khatello | 552-663 ℃ |

| Ho tima | 552-663 ℃ |

DIN 42CrMo4 Alloy Steel Mechanical Properties

| Boholo Ø mm | Khatello ea lihlahisoa | Ultimate tensile stress, | Elongation | Ho thatafala HB | Ho thatafala |

| Rp0.2,N/nn2, mets. | Rm,N/nn2 | A5,%, mets. | KV, Joule, min. | ||

| <40 | 750 | 1000-1200 | 11 | 295-355 | 35 ka 20ºC |

| 40-95 | 650 | 900-1100 | 12 | 265-325 | 35 ka 20ºC |

| >95 | 550 | 800-950 | 13 | 235-295 | 35 ka 20ºC |

| Rm - Matla a tsitsitseng (MPa) (Q +T) | ≥635 |

| Rp0.2 0.2% matla a bopaki (MPa) (Q +T) | ≥440 |

| KV - Matla a Impact (J) (Q +T) | +20 ° |

| A - Min. elongation at fracture (%)(Q +T) | ≥20 |

| Z - Phokotso ea karolo ea sefapano ho robeha (%)(N+Q +T) | ≥50 |

| Brinell hardness (HBW): (Q +T) | ≤192HB |

TLHAHISOLESELING E 'NGOE

KOPO LEKHOTSO

KAPA BITSA: 86-21-52859349