1. Isothermal been abuurashowaa in la ilaaliyo heerkulka billet joogto ah inta lagu jiro habka samaynta oo dhan.Isothermal been abuurashowaxaa loo isticmaalaa in laga faa'iidaysto caagga sare ee biraha qaarkood heerkulka joogtada ah ama si loo helo dhismayaal iyo hanti gaar ah. Foornaynta Isothermal waxay u baahan tahay caaryada iyo billet in lagu hayo heerkul joogto ah si wadajir ah, taas oo u baahan kharash aad u sarreeya oo loo isticmaalo kaliya hababka foornada iyo cadaadiska gaarka ah, sida samaynta superplastic.

2. Been abuurashowax ka bedeli kara qaab-dhismeedka biraha iyo hagaajinta waxqabadka birta. Kadibbeen abuur kululxinjirowga, xaaladda kabka asalka ah ee dabacsan, dalool, dildilaaca micro waa la cufan ama welded; Crystal dendritic-kii asalka ahaa waa la jebiyey si uu hadhuudhku u fiicnaado. Isla mar ahaantaana, beddelo kala soocidda carbide asalka ah iyo qaybinta aan sinnayn, si ururka waa labis, si aad u hesho cufan gudaha, labis, ganaax, waxqabadka dhamaystiran oo wanaagsan, isticmaalka la isku halayn karo ee forgings. Kadibbeen abuur kululqallafsanaanta, birta waa qaab-dhismeedka fiber; Ka dib qallafsanaanta qaboobaha, kiristaalo biraha ayaa muujinaya nidaam.

3.been abuurashowaa in la sameeyo socodka balaastikada birta ah oo laga sameeyay qaabka la rabo ee workpiece. Mugga birta ayaa isbeddelin ka dib socodka caagga ah ee xoogga dibadda, iyo birta had iyo jeer waxay u socotaa qaybta ugu yar ee iska caabbinta. In wax soo saarka, qaabka workpiece waxaa inta badan la xakameeyo si waafaqsan sharciyadan, iyo deformation of sawirka xanaaqa, reaming, foorarsiga iyo sawir qoto dheer waa la xaqiiqsaday.

4.ahworkpiece been abuur ahcabbirku waa sax, ku habboon abaabulka wax-soo-saarka ballaaran.Dhimasho been abuurasho, extrusion, shaabadeynta iyo codsiyada kale ee cabbirka samaynta caaryada waa sax oo deggan. Mashiinno been abuur ah oo tayo sare leh iyo khadka wax-soo-saarka been-abuurka tooska ah ayaa loo isticmaali karaa in lagu abaabulo wax-soo-saarka mass ee khaaska ah ama wax-soo-saarka ballaaran.

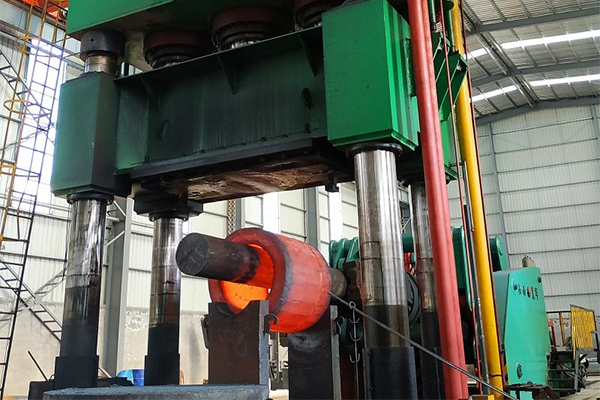

5.Habka wax soo saarka eebeen abuurashowaxaa ka mid ah faaruqinta, kululaynta iyo ka-hortagga been-abuurka ka hor inta aan la samayn; Daawaynta kulaylka, nadiifinta, hagaajinta iyo kormeerka shaqada ka dib samaynta. Mashiinada been abuurka ah ee sida caadiga ah loo isticmaalo waxay leeyihiin dubbe been abuur ah, madbacadaha haydarooliga iyo mashiinada farsamada. Dubbada been-abuurka ah waxay leedahay xawaare saameyn weyn leh, kaas oo ku habboon socodka caagga ah ee birta, laakiin waxay soo saari doontaa gariir; Saxafada hydraulic waxay isticmaashaa foornada static, waxay faa'iido u leedahay in lagu dhejiyo birta iyo hay'adda hagaajinta, shaqadu waa mid deggan, laakiin wax soo saarku waa hooseeyaa; Saxafada makaanikku waxay leedahay istaroog go'an, kaas oo ay fududahay in la xaqiijiyo makaanaynta iyo otomatiga.

Mustaqbalka, thefarsamada been abuurkahagaajin doonaa tayada gudaha eeqaybo been abuur ah, horumarinta saxda ahbeen abuurashoiyo tignoolajiyada saxda ah ee stamping, horumarintaqalabka been abuurkaiyowax soo saar been abuur ahline leh wax soo saar sare iyo shahaadada otomaatiga, horumarintabeen abuurasho dabacsannidaamka samaynta, iyo horumarinta cusubalaabta been abuurka ahiyofarsamaynta been abuurkahababka. Si loo hagaajiyo tayada gudaha eebeen abuurasho, inta badan waa in la hagaajiyo sifooyinkooda farsamo (xoogga, caagagga, adkaanta, xoogga daalka) iyo isku halaynta. Tani waxay u baahan tahay in si fiican loo isticmaalo aragtida qallafsanaanta balaastiigga; Codso agab tayo sare leh oo gudaha ah; Sax kuleylinta ka hor been-abuurka iyo daawaynta kulaylka; Tijaabooyin aad u adag oo baaxad leh oo aan burburinayn ee foorjarida.

Waqtiga boostada: Jan-25-2021