1. Isothermal forgingndiko kuchengetedza tembiricha yebillet nguva dzose panguva yese yekuumba.Isothermal forginginoshandiswa kutora mukana wepamusoro wepurasitiki yemamwe masimbi pakupisa nguva dzose kana kuwana zvimiro uye zvivakwa. Isothermal forging inoda kuti mold uye billet zvichengetwe patembiricha yenguva dzose pamwe chete, izvo zvinoda mutengo wakakwira uye zvinongoshandiswa kune yakakosha yekuforoma nekutsikirira maitiro, senge superplastic kuumba.

2. Forginginogona kushandura chimiro chesimbi uye kuvandudza kushanda kwesimbi. Mushurekupisa kuumbaiyo ingot, iyo yekutanga yakakandwa mamiriro eyakasununguka, pore, micro crack inobatanidzwa kana welded; Iyo yepakutanga dendritic crystal inoputsika kuita kuti zviyo zvive zvakanaka. Panguva imwecheteyo, shandura iyo yepakutanga carbide segregation uye kusaenzana kugoverwa, kuitira kuti sangano rive yunifomu, kuitira kuti uwane mukati dense, yunifomu, yakanaka, yakanaka yakazara mashandiro, yakavimbika kushandisa forgings. Mushurekupisa kuumbadeformation, iyo simbi ine fibrous chimiro; Mushure mekutonhora kwekugadzira deformation, makristasi esimbi anoratidza kurongeka.

3.forgingndiko kuita kuti simbi yepurasitiki ibude uye iite muchimiro chaidiwa cheworkpiece. Huwandu hwesimbi hahuna kuchinjika mushure mekuyerera kwepurasitiki nechisimba chekunze, uye simbi inogara ichiyerera kusvika kune chikamu chekushomeka. Mukugadzira, chimiro cheworkpiece chinowanzodzorwa zvinoenderana nemirairo iyi, uye deformation yekugumburisa kudhirowa, kudzokorora, kukotama uye kudhirowa kwakadzika kunoitwa.

4.thekugadzira workpiecesaizi yakarurama, inobatsira kurongeka kwekugadzirwa kwehuwandu.Kufa kuhura, extrusion, stamping uye mamwe maapplication eiyo mold yekugadzira saizi ndeyechokwadi uye yakagadzikana. Yakakwirira inoshanda yekugadzira muchina uye otomatiki yekugadzira yekugadzira mutsara inogona kushandiswa kuronga yakasarudzika misa kugadzirwa kana kugadzirwa kwakawanda.

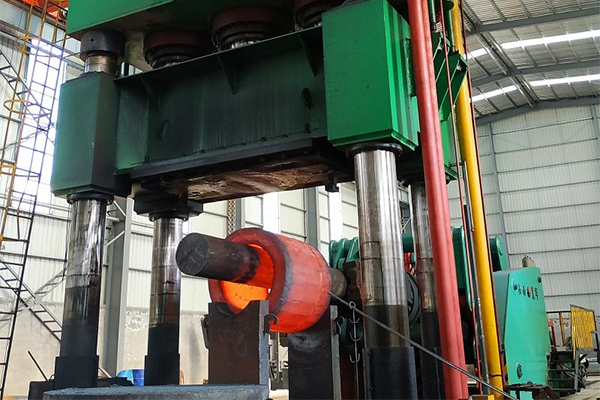

5.Nzira yekugadzira yeforgingzvinosanganisira kusavhara, kudziyisa uye pretreatment yekuforoma isina chinhu isati yaumba; Kurapa kwekupisa, kuchenesa, kuenzanisa uye kuongororwa kweworkpiece mushure mekugadzira. Inowanzo shandiswa kugadzira muchina une nyundo yekugadzira, hydraulic press uye mechanic press. Kugadzira nyundo ine hombe yekumhanyisa velocity, iyo inoenderana nesimbi yepurasitiki kuyerera, asi inoburitsa vibration; Iyo hydraulic press inoshandisa iyo static forging, inobatsira pakugadzira kuburikidza nesimbi uye sangano rekuvandudza, basa rakagadzikana, asi kubereka kwakaderera; Iyo mechanical press yakagadzirisa sitiroko, zviri nyore kuona mechanization uye otomatiki.

Mune ramangwana, thekugadzira tekinorojiichavandudza kunaka kwemukati weforging parts, kukudziridza kururamaforginguye chaiyo stamping tekinoroji, gadziraforging equipmentuyekugadzira kugadzirakuenderana nekugadzirwa kwepamusoro uye otomatiki degree, gadziraflexible forgingkugadzira system, uye kugadzira itsvaforging materialsuyeforging processingnzira. Kuvandudza hutano hwemukati hweforgings, inonyanya kuvandudza maitiro avo emagetsi (simba, plastiki, kuoma, kuneta simba) uye kuvimbika. Izvi zvinoda kushandiswa zviri nani kwesimbi plastiki deformation theory; Isa zviri nani zvemhando yepamusoro zvinhu; Yakarurama pre-forging kudziyisa uye forging kupisa kurapwa; Kuwedzera kuomarara uye kwakawedzera kusaparadza kuyedza kwefogi.

Nguva yekutumira: Jan-25-2021