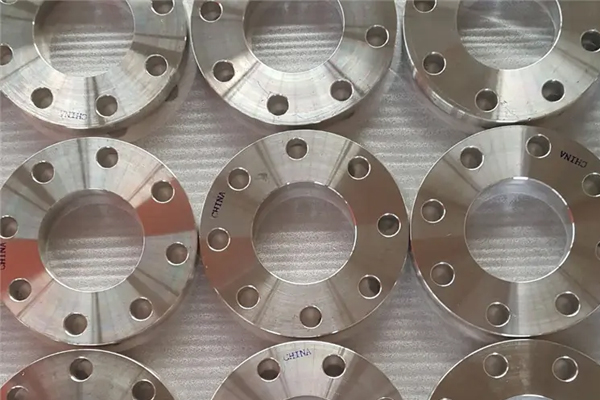

Flat welding flangemaererano nezvaunofariraforgingkufa kufamba, inogona kukamurwa kuita swing rolling, swing rotaryforging, kuromba, kukunguruka kweweji, kutenderedza mhete, kukunguruka zvichingodaro. Precision forging inogona zvakare kushandiswa mukutenderedza, swing rotary forging uye ring rolling. Roll forging uye cross rolling inogona kushandiswa sepretreatment yezvinhu zvitete kuvandudza kushandiswa kwezvinhu. Kufanana nemahara forging, rotary forging inoumbwa zvishoma uye ine mukana wekuumba kunyangwe simba rekugadzira riri shoma pane saizi yekugadzira. Complex forgings inogona kupedzwa mune imwe kana akawanda maitiro. Nekuda kwekuti hapana maburr edges, nzvimbo yekutakura inoderedzwa uye mutoro unodiwa unoderedzwa.

Izviforgingnzira inoita kuti zvinhu zviwedzere kubva padyo neflange kana ichigadzirwa. Nekuti chinhambwe pakati pekufa uye nzvimbo yemahara chakasiyana, zvakaoma kuvimbisa iyo chaiyo. Naizvozvo, nekudzora mafambiro eiyo forging die uye iyo rotary forging process nekombuta, zvigadzirwa zvine chimiro chakaomarara uye kunyatso hunyanzvi zvinogona kugadzirwa. Hongu, ndinogona kuzviita. Kuwanikwa nesimba rekugadzira rakaderera. Steam turbine blades nemamwe marudzi uye saizi hombeforgingskugadzira.

Flat welding flange forginginogona kukamurwa kuita yemaharaforging, zvinogumbura, extrusion, kufa forging, kuvharika kufa forging uye kuvharika kunogumbura forging. Muzhinji, kuumba mune recrystallization tembiricha renji inonzi inopisa fogi, pakamuri tembiricha pasina kudziyisa forging inonzi inotonhora forging. Riniflat welded flangesvariforgedpakupisa kwakadzika, zviyero zveforgingszvishoma kuchinja. Kana yakaumbwa pazasi 700 ℃, inenge isina oxide sikero inoumbwa uye hapana pamusoro decarburization inoitika.

Flat welding flangemisimboti yekuisa chisimbiso: mabhaudhi maviri ekuisa chisimbiso anodzvanya paflange gasket kuti agadzire chisimbiso, icho chinogona zvakare kutungamira mukukuvadzwa chisimbiso. Kuti uchengetedze chisimbiso, zvakakosha kuchengetedza simba guru rebhoti, saka wedzera bhoti. Mabhoti makuru anofanira kufanana nenzungu huru. Izvi zvinoreva kuti iwe uchada mabhaudhi makuru edhayamita kuti ugadzire mamiriro ekusimbisa nati.

Note forflat welding flange

1. Ndiro yesimbi inoshandiswa kugadziraflat welded flangesinogadzirwa uye inoshandiswa kuburikidza ne ultrasonic inspection pasina delamination, kuitira kuti uone hutano hwakanaka uye matambudziko ekushanda, uye inogadzirwa uye yakaedzwa maererano nezvinodiwa zvehutano, ndiro yesimbi haina matambudziko ehutano.

2. Simbi inochekwa kuita mitsetse pamwe chete negwara rekukunguruka, uye ipapo yakakotama uye butt yakasungirirwa muzvindori, ichiita denderedzwa pamusoro pesimbi. Humburumbira. Mukugadzirwa kweflange-welded flanges, ndiro yesimbi haifaniri kugadzirwa zvakananga kumutsipa weflange, asi inogadzirwa uye inogadzirwa uchishandisa imwe nzira.

Nguva yekutumira: Jun-13-2022