Mugadziri weOpen Die Forgings - Forged Cylinders – DHDZ

Mugadziri weVhura Die Forgings - Forged Cylinders - DHDZ Detail:

Vhura Die ForgingsMugadziri muChina

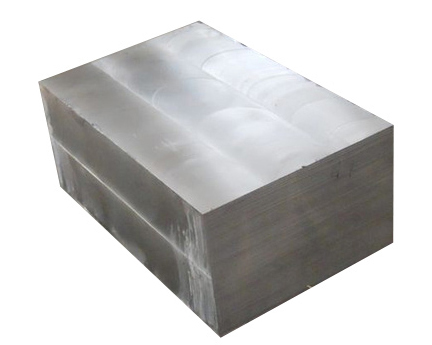

FORGED CYLINDER

| Max. OD | Max. Urefu | Max. Kurema |

| 4000mm | 10 000mm | 30 Matani |

DHDZ inogadzira isina musono, inorema madziro masimbi masilinda uye maoko mune dzakasiyana siyana zvigadziriso zvinoenderana nezvinodiwa nevatengi. Seamless forged hollows yakanakira kushandiswa kwepamusoro-kushushikana uye nharaunda dzakaomarara nekuda kwekugara kwayo, simba uye kushora. Hollows inogona kugadzirwa kwete chete mune yakatwasuka cylindrical chimiro, asi nekusiyana kusingagumi kweOD uye maID, kusanganisira matepi.

Pamusoro pezvo DHDZ inopa ese akadzika magadzirirwo anosanganisira kupisa kurapwa, machining uye mechanic uye isiri-kuparadza kuyedza, pakukumbira. Bata nesu nhasi nezvako chaizvo zvakatemwa, timu yedu ichashanda newe kuti titore mari pane zvatinogona kudzikisa kutambisa zvinhu uye kuderedza kusashanda zvakanaka.

Zvinowanzoshandiswa zvinhu: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV|EN 1.4201 |42CrMo4

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., seISO yakanyoreswa yakanyoreswa mugadziri wekugadzira, inovimbisa kuti forgings uye/kana mabara ane homogenous mumhando uye haana anomalies izvo zvinokanganisa ma mechanika zvivakwa kana machining midziyo yechinhu.

Nyaya: Simbi Giredhi AISI 4130 Alloy Steel (UNS G41300)

Zvinhu Zvenyama

| Properties | Metric | Vadivelu Comedy Mperial |

| Density | 7.85 g/cm3 | 0.284 lb/in³ |

| Melting point | 1432°C | 2610°F |

AISI 4130 Alloy Steel Relevant Specifications uye Equivalents

| AISI 4130 | C | Mn | Si | P | S | Cr | Mo | Ni | Cu | Mo |

| 0.280 - 0.330 | 0.40 - 0.60 | 0.15 - 0.30 | 0.030 max | 0.040 max | 0.80-1.10 | 0.15-0.25 | 0.25 max | 0.35 max | 0.15-0.25 |

| ASTM A29/A29M | DIN17350 | JIS G4404 | GB/T 1229 | ISO 683/18 |

| AISI 4130/ G41300 | 1.7218/25CrMo4 | SMN 420 | 25CrMo4 | 25CrMo4 |

Applications

Dzimwe dzakajairika nzvimbo dzekushandisa dzeAISI 4130:

Maindasitiri emafuta negasi - semiviri yakaumbwa nemavharuvhu nemapombi

Ndege dzekutengesa, ndege injini inokwira

Ndege dzehondo

Automotive

Zvishandiso zvemuchina

Zvishandiso zveHydraulic

Auto racing

Aerospace

Agricultural and defense industry etc.

AISI 4130 Forged Cylinder, Yakaderera alloy Steel forgings yemafuta uye gasi maindasitiri.

Kukura: φ774.8 0xφ317.0XH825.5mm

Kugadzira uye Kupisa Kurapa

Machinability - AISI 4130 simbi inogona kugadzirwa nyore nyore uchishandisa yakajairika nzira. Zvisinei, kugadzira kunova kwakaoma kana kuoma kwesimbi kuchiwedzerwa.

Kugadzira AISI 4130 simbi inogona kuitwa mune annealed mamiriro.

● Welding yeAISI 4130 simbi inogona kuitwa nenzira dzose dzekutengesa.

● Heat Treatment - AISI 4130 simbi inopisa pa 871 ° C (1600 ° F) uye inobva yadzimwa mumafuta. Iyi simbi inowanzopisa-yakagadziriswa patembiricha kubva pa899 kusvika 927°C (1650 kusvika 1700°F).

● Kugadzirwa kweAISI 4130 simbi inogona kuitwa pa954 kusvika 1204 ° C (1750 kusvika 2200 ° F).

● Kupisa kushanda kweAISI 4130 simbi kunogona kuitwa pa816 kusvika 1093 ° C (1500 kusvika 2000 ° F).

● AISI 4130 simbi inogona kutonhora yakashanda uchishandisa nzira dzakajairika.

● AISI 4130 simbi inogona kuvharwa pa843 ° C (1550 ° F) inoteverwa nemhepo inotonhorera pa482 ° C (900 ° F).

● Kupisa kweAISI 4130 simbi inogona kuitwa pa 399 kusvika 566 ° C (750 kusvika 1050 ° F), zvichienderana nehuwandu hwesimba hunodiwa.

● Kuomeswa kwesimbi yeAISI 4130 kunogona kuitwa nekushanda kunotonhora kana kupisa kupisa.

Zvimwe zvezvishandiso zvikuru zveAISI 4130 alloy simbi zviri mumakombi einjini dzendege uye akaiswa tubing.

Kugadzira (Kupisa Basa) Kudzidzira, Kupisa Kurapa Maitiro

| Forging | 1093-1205 ℃ |

| Annealing | 778-843 ℃ choto chinotonhorera |

| Tempering | 399-649℃ |

| Normalizing | 871-898 ℃ mhepo inotonhorera |

| Austenize | 815-843 ℃ kudzima mvura |

| Kushungurudzika Kuderedza | 552-663 ℃ |

| Quenching | 552-663 ℃ |

| Rm - Kusimba simba (MPa) (Q +T) | ≥930 |

| Rp0.2 0.2% chiratidzo chesimba (MPa) (Q +T) | ≥785 |

| KV - Impact simba (J) (Q +T) | +20° |

| A - Min. kureba pakutyoka (%)(Q +T) | ≥12 |

| Z - Kuderedzwa kwechikamu chemuchinjiko pakutyoka (%) (N+Q +T) | ≥50 |

| Brinell kuoma (HBW): (Q +T) | ≤229HB |

RUDZIDZO RWEKUWEDZERA

KUMBIRA KUPIWA NHASI

KANA KUFANA: 86-21-52859349

4130

4130

New-4130-Alloy-Steel

New-4130-Alloy-Steel

Mifananidzo yezvigadzirwa:

Related Product Guide:

Isu tinofunga zvinofungwa nevatengi, iko kukurumidza kwekuita zvinhu panguva yezvido zvemutengi chinzvimbo chedzidziso, zvichibvumira zviri nani zvemhando yepamusoro, kuderedzwa kwemitengo yekugadzira, miripo inonzwisisika, yakahwina vatengi vatsva nevechinyakare rutsigiro uye tsigiro yeMugadziri weOpen Die Forgings - Forged Cylinders - DHDZ , Chigadzirwa ichi, Chigadzirwa, Israel, Bedera tichitungamirwa nezvido zvevatengi, tichivavarira kuvandudza kugona uye kunaka kwesevhisi yevatengi, tinogara tichivandudza zvinhu uye tichipa mamwe masevhisi akadzama. Tinogamuchira nemoyo wese shamwari kuti dzitaurirane nezvebhizinesi uye kutanga kushandira pamwe nesu. Tinovimba kubatana maoko neshamwari mumaindasitiri akasiyana kugadzira ramangwana rakajeka.

Matambudziko anogona kukurumidza uye zvinogadziriswa kugadziriswa, zvakakodzera kuvimba uye kushanda pamwe chete.