1. isothermal forgingali mu njira yonse yopangira kutentha kwa billet kuti asunge mtengo wokhazikika.Kupanga kwa isothermalndikugwiritsa ntchito mokwanira pulasitiki yapamwamba yazitsulo zina pa kutentha komweko, kapena kupeza microstructure yeniyeni ndi katundu. Kupanga kwa Isothermal kumafuna kutentha kosalekeza kwa kufa ndi billet palimodzi, komwe kumafunikira mtengo wokwera ndipo kumangogwiritsidwa ntchitokupanga kwapaderanjira, monga superplastic kupanga.

2.kupangaakhoza kusintha zitsulo kapangidwe, kusintha zitsulo ntchito. Pambuyokutentha kwachangu, choyambirira kuponyedwa lotayirira, pores, yaying'ono ming'alu ndi zina zotero ndi akaumbike kapena welded; Makhiristo oyambilira a dendritic amasweka ndipo njere zimakhala zabwino. Pa nthawi yomweyo kusintha choyambirira tsankho carbide ndi kugawa m'malo, kupanga kapangidwe yunifolomu, kuti apeze mkati wandiweyani, yunifolomu, chabwino, ntchito bwino mabuku, ntchito yodalirika forging. Pambuyo otentha forging mapindikidwe, zitsulo ndi fibrous minofu; Pambuyo pozizira kozizira, makristasi achitsulo amasonyeza dongosolo.

3. kupangandi kupanga pulasitiki yachitsulo ikuyenda ndi kupanga mawonekedwe ofunikira a workpiece. Kuchuluka kwachitsulo kumakhala kosalekeza pambuyo pa kutuluka kwa pulasitiki chifukwa cha mphamvu yakunja, ndipo chitsulo nthawi zonse chimayenda kumalo osakanizidwa kwambiri. Popanga, mawonekedwe a workpiece nthawi zambiri amawongoleredwa molingana ndi malamulowa kuti azindikire zojambula zokhumudwitsa, kukulitsa dzenje, kupindika, kujambula ndi mapindikidwe ena.

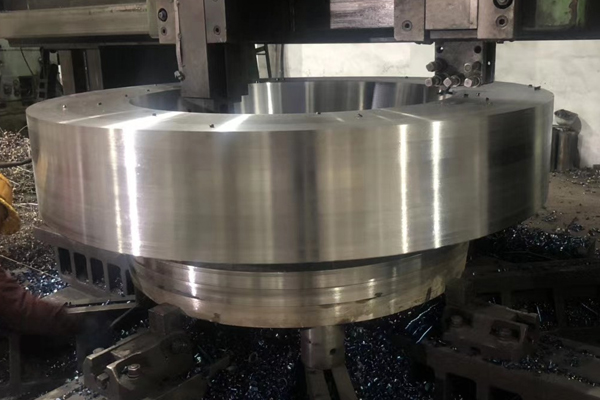

4. kupangakunja kwa workpiece kukula ndi zolondola, zabwino kupanga misa bungwe.Ifa kusaka, extrusion, stamping ndi ntchito zina za nkhungu kupanga kukula molondola, khola. Makina opangira makina opangira makina komanso makina opangira okhawo amatha kugwiritsidwa ntchito kukonza akatswiri opanga misa kapena kupanga misa.

5. kupangakupanga kumaphatikizapo kupanga billet blanking,kupangabillet kutentha ndi pretreatment asanapange; Kutentha mankhwala, kuyeretsa, calibration ndi kuyendera workpiece pambuyo kupanga. Makina opangira omwe amagwiritsidwa ntchito kwambiri amakhala ndi nyundo, makina osindikizira a hydraulic ndi makina osindikizira. Kupanga nyundo kumakhala ndi liwiro lalikulu, lothandizira kuyenda kwazitsulo zapulasitiki, koma kutulutsa kugwedezeka; Makina osindikizira a Hydraulic okhala ndi static forging, amathandizira kupanga zitsulo ndikuwongolera bungwe, ntchito yokhazikika, koma zokolola zochepa; Makina atolankhani okhazikika, osavuta kuzindikira makina ndi makina.

Mtsogolomu,kupangandi kukanikiza ukadaulo udzakulitsa luso lamkati la zida zopangira ndi kukanikiza, kupanga ukadaulo wowongolera ndi kupondaponda, kupanga zida zopangira ndi kupanga mzere wopangira zopanga zapamwamba komanso zodziwikiratu, kukhala zosinthika.kupangandi kukanikiza dongosolo, kupanga latsopanokupangazipangizo ndikupangaprocessing njira. Kuwongolera mkati khalidwe la forging mbali makamaka kusintha makina katundu (mphamvu, plasticity, toughness, kutopa mphamvu) ndi kudalirika. Izi zimafuna bwino ntchito zitsulo pulasitiki mapindikidwe chiphunzitso; Kugwiritsa ntchito zinthu zabwino kwambiri zakuthupi; Zolondolakupanga kaleKutentha ndi kukonza kutentha; Kuyesa kopitilira muyeso komanso kokulirapo kosawononga kwa zida zopangira.

Nthawi yotumiza: Oct-18-2021