1. Kupanga kwa isothermalndi kusunga kutentha kwa billet nthawi zonse popanga ndondomeko.Kupanga kwa isothermalamagwiritsidwa ntchito kupezerapo mwayi pa pulasitiki yapamwamba yazitsulo zina pa kutentha kosasintha kapena kupeza mapangidwe ndi katundu. Isothermal forging imafuna nkhungu ndi billet kuti zisungidwe kutentha kosalekeza palimodzi, zomwe zimafuna mtengo wokwera ndipo zimangogwiritsidwa ntchito popanga komanso kukakamiza, monga kupanga superplastic.

2. Kupangaimatha kusintha kapangidwe kachitsulo ndikuwongolera magwiridwe antchito achitsulo. Pambuyokutentha kwachanguingot, choyambirira kuponyedwa dziko lotayirira, pore, micro crack ndi akaumbike kapena welded; Choyambirira cha dendritic crystal chathyoledwa kuti mbewuyo ikhale yabwino. Panthawi imodzimodziyo, sinthani tsankho lapachiyambi la carbide ndi kugawa kosagwirizana, kuti bungwe likhale yunifolomu, kuti mupeze mkati wandiweyani, yunifolomu, yabwino, yogwira ntchito bwino, yodalirika yogwiritsira ntchito forgings. Pambuyokutentha kwachangumapindikidwe, zitsulo ndi fibrous dongosolo; Pambuyo pa kuzizira kopangira mapindikidwe, makristasi azitsulo amawonetsa dongosolo.

3.kupangandi kupanga pulasitiki zitsulo kuyenda ndi kupanga mu mawonekedwe ankafuna workpiece. Kuchuluka kwachitsulo sikunasinthe pambuyo pa kutuluka kwa pulasitiki ndi mphamvu yakunja, ndipo chitsulo nthawi zonse chimayenda ku gawo laling'ono. Popanga, mawonekedwe a workpiece nthawi zambiri amawongoleredwa molingana ndi malamulowa, ndipo kusinthika kwa zojambula zokhumudwitsa, kubwezeretsanso, kupindika ndi kujambula kozama kumakwaniritsidwa.

4.ndikupanga workpiecekukula ndi kolondola, kothandiza ku bungwe la kupanga misa.Ifa kusaka, extrusion, stamping ndi ntchito zina za kukula kwa nkhungu kupanga ndizolondola komanso zokhazikika. Makina opanga bwino kwambiri komanso makina opangira okhawo amatha kugwiritsidwa ntchito kukonza zida zapadera kapena kupanga misa.

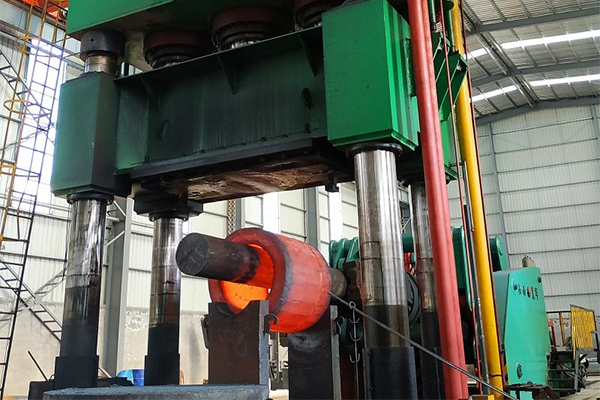

5.Njira yopangakupangakumaphatikizapo kutseka, kutenthetsa ndi kukonzetsera kufota popanda kanthu musanapange; Kutentha mankhwala, kuyeretsa, calibration ndi kuyendera workpiece pambuyo kupanga. Makina opangira omwe amagwiritsidwa ntchito kwambiri amakhala ndi nyundo, makina osindikizira a hydraulic ndi makina osindikizira. Kupanga nyundo kumakhala ndi liwiro lalikulu, lomwe limathandizira kuyenda kwa pulasitiki yachitsulo, koma limatulutsa kugwedezeka; Makina osindikizira a hydraulic amagwiritsa ntchito static forging, amapindula popanga zitsulo ndi bungwe lothandizira, ntchitoyo ndi yokhazikika, koma zokolola ndizochepa; Makina osindikizira ali ndi sitiroko yokhazikika, yomwe ndiyosavuta kuzindikira makina ndi makina.

M'tsogolomu, aukadaulo wopangaadzakonza mkati khalidwe lakupangira magawo, khalani olondolakupangandi luso lolondola kwambiri la masitampu, khazikitsanizida zopangirandikupanga kupangazigwirizane ndi zokolola zapamwamba ndi digiri ya automation, khazikitsaniflexible forgingkupanga dongosolo, ndikupanga zatsopanozida zopangirandikukonza processingnjira. Kupititsa patsogolo khalidwe lamkati lazojambula, makamaka kuwongolera zinthu zawo zamakina (mphamvu, pulasitiki, kulimba, mphamvu ya kutopa) ndi kudalirika. Izi zimafuna bwino ntchito zitsulo pulasitiki mapindikidwe chiphunzitso; Ikani zida zabwino kwambiri; Kuwotchera koyenera koyambirira ndi kukonza kutentha; Kuyesa kopitilira muyeso komanso kozama kosawononga kwa ma forgings.

Nthawi yotumiza: Jan-25-2021