Flange kuwotcherera flangemalinga ndi zomwe mumakondakupangakufa kuyenda, zikhoza kugawidwa mu kugwedezeka akugudubuzika, kusambira rotarykupanga, kugubuduza mpukutu, kupindika mphero, kupindika mphete, kupindika ndi zina zotero. Kukonzekera kolondola kungagwiritsidwenso ntchito pakugudubuza, kugwedera mozungulira komanso kupindika mphete. Ma roll forging and cross rolling atha kugwiritsidwa ntchito ngati chiwongolero cha zida zowonda kuti zithandizire kugwiritsa ntchito zinthu. Monga kufota kwaulere, kufota kozungulira kumapangidwa pang'ono ndipo kumakhala ndi mwayi wopanga ngakhale mphamvu yopangirayo ili yochepa kuposa kukula kwake. Zolemba zovuta zimatha kumalizidwa munjira imodzi kapena zingapo. Chifukwa palibe ma burr m'mphepete, malo opangirako amachepetsedwa ndipo katundu wofunikira amachepetsedwa.

IzikupangaNjirayi imapangitsa kuti zinthu ziwonjezeke kuchokera pafupi ndi flange zikamapangidwa. Chifukwa mtunda wapakati pa kufa ndi malo aulere ndi wosiyana, ndizovuta kutsimikizira kulondola. Chifukwa chake, powongolera mayendedwe a forging kufa ndi njira yokhotakhota pamakompyuta, zinthu zokhala ndi mawonekedwe ovuta komanso kulondola kwambiri zitha kupangidwa. Inde, ndikhoza. Zopezedwa ndi mphamvu zochepa zopangira. Nthunzi turbine masamba ndi mitundu ina ndi lalikulu kukulazojambulakupanga.

Flange kuwotcherera flange kupangaakhoza kugawidwa mfulukupanga, kukwiyitsa, kutulutsa, kupangira kufa, kutsekereza kufa kotsekera komanso kutsekeka kosokoneza. Nthawi zambiri, kupanga mu recrystallization kutentha osiyanasiyana kumatchedwa otentha forging, pa firiji popanda Kutentha forging amatchedwa ozizira forging. Litima flanges otsekemerandizachinyengopa kutentha otsika, miyeso yazojambulaosasintha. Ikapangidwa pansi pa 700 ℃, pafupifupi sikelo ya oxide imapangidwa ndipo palibe decarburization yamtunda yomwe imachitika.

Flange kuwotcherera flangemfundo yosindikiza: malo awiri osindikizira a ma bolts amasindikiza pa flange gasket kuti apange chisindikizo, chomwe chingapangitsenso kuwonongeka kwa chisindikizo. Kuti musunge chisindikizocho, ndikofunikira kusunga mphamvu yayikulu ya bawuti, motero onjezerani bawuti. Zovala zazikulu ziyenera kugwirizana ndi mtedza waukulu. Izi zikutanthauza kuti mudzafunika mabawuti okulirapo kuti mupange mikhalidwe yomangitsa mtedza.

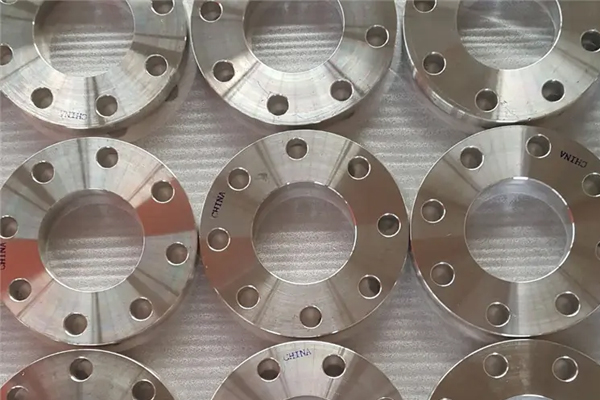

Chidziwitso chaflat kuwotcherera flange

1. Chitsulo chomwe chimagwiritsidwa ntchito popangama flanges otsekemeraamapangidwa ndi kugwiritsidwa ntchito kupyolera mu kuyendera akupanga popanda delamination, kuti azindikire ubwino wabwino ndi mavuto a ntchito, ndi kupanga ndi kuyesedwa malinga ndi zofunikira za khalidwe, mbale yachitsulo ilibe mavuto abwino.

2. Chitsulo chimadulidwa kukhala mizere motsatira njira yozungulira, ndiyeno amapindika ndi matako amawotcherera mu mphete, kupanga chozungulira pamwamba pazitsulo. Silinda. Popanga ma flanges opangidwa ndi lathyathyathya, mbale yachitsulo siyenera kupangidwa molunjika ku khosi la flange, koma imapangidwa ndi makina pogwiritsa ntchito njira inayake.

Nthawi yotumiza: Jun-13-2022