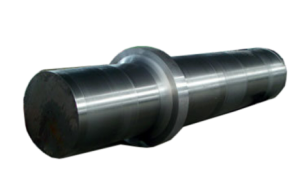

Shaft Yopangidwa

Open Die Forgings Wopanga Ku China

SHAFT YOPHUNZITSIDWA / STEP SHAFT / SPINDLE / AXLE SHAFT

Minda yogwiritsira ntchito forgings shaft ndi

Shaft forgings (makina opangira ma shaft) Zopangira ma shaft ndi zinthu za cylindrical zomwe zimavalidwa pakati pa gudumu kapena pakati pa gudumu kapena pakati pa giya, koma zochepa ndi zazikulu. Shaft ndi gawo lamakina lomwe limathandizira gawo lozungulira ndikuzungulira nalo kuti lipereke kusuntha, torque kapena nthawi yopindika. Nthawi zambiri, ndi mawonekedwe achitsulo, ndipo gawo lililonse limatha kukhala ndi mainchesi osiyanasiyana. Zigawo za makina zomwe zimapanga kayendedwe ka slewing zimayikidwa pamtengo. Chinese dzina kutsinde forging mtundu kutsinde, mandrel, galimoto kutsinde zinthu ntchito 1, carbon zitsulo 35, 45, 50 ndi zina apamwamba mpweya structural zitsulo chifukwa cha mkulu mabuku katundu makina, ntchito zambiri, amene 45 zitsulo ntchito kwambiri. Kuti apititse patsogolo makina ake, normalizing kapena quenching ndi tempering ayenera kuchitika. Pazitsulo zamapangidwe zomwe sizofunikira kapena zokhala ndi mphamvu zochepa, zitsulo zamtundu wa carbon monga Q235 ndi Q275 zingagwiritsidwe ntchito. 2, aloyi chitsulo Aloyi Chitsulo ali apamwamba makina katundu, koma mtengo ndi okwera mtengo, makamaka ntchito shafts ndi zofunika zapadera. Mwachitsanzo, ma shafts othamanga kwambiri omwe amagwiritsa ntchito zitsulo zotsetsereka, zomwe zimagwiritsidwa ntchito kwambiri ndi zitsulo zokhala ndi carbon alloy structural 20Cr ndi 20CrMnTi, zimatha kupititsa patsogolo kukana kwa magazini pambuyo pa carburizing ndi kuzimitsa; shaft ya rotor ya jenereta ya turbo imagwira ntchito pansi pa kutentha kwambiri, kuthamanga kwambiri komanso kulemedwa kwakukulu. Ndi zinthu zabwino zamakina otentha kwambiri, zitsulo zamapangidwe a alloy monga 40CrNi ndi 38CrMoAlA zimagwiritsidwa ntchito nthawi zambiri. Chopanda kanthu cha shaft chimakonda zopangira, zotsatiridwa ndi zitsulo zozungulira; Pazinthu zazikulu kapena zovuta, chitsulo choponyedwa kapena chitsulo cha ductile chingaganizidwe. Mwachitsanzo, kupanga crankshaft ndi camshaft kuchokera ku chitsulo cha ductile kuli ndi ubwino wa mtengo wotsika, kuyamwa kwabwino kwa kugwedezeka, kutsika kwachangu kupsinjika maganizo, ndi mphamvu zabwino. Mtundu wamakina wa shaft ndi mtengo, womwe umazunguliridwa kwambiri, kotero kupsinjika kwake nthawi zambiri kumakhala kozungulira. Mitundu yolephera yomwe ingatheke ndiphatikizira kuthyoka kwa kutopa, kuphulika kwakukulu, komanso kupunduka kwambiri. Ziwalo zina zokhala ndi ma hubs nthawi zambiri zimayikidwa pa shaft, motero ma shaft ambiri ayenera kupangidwa kukhala masitepe opindika okhala ndi makina ambiri. Kapangidwe Kapangidwe Kapangidwe Kapangidwe ka shaft ndi gawo lofunikira pozindikira mawonekedwe oyenera komanso kukula kwake kwa shaft. Zimapangidwa ndi mtundu, kukula ndi malo a gawo lomwe layikidwa pamtengowo, momwe gawolo limapangidwira, chikhalidwe, mayendedwe, kukula ndi kugawa kwa katundu, mtundu ndi kukula kwa chonyamulira, chopanda kanthu cha shaft, kupanga ndi kusonkhana, kukhazikitsa ndi kuyendetsa, shaft The deformation ndi zinthu zina zimagwirizana. Wopanga amatha kupanga molingana ndi zofunikira za shaft. Ngati ndi kotheka, ziwembu zingapo zingafanane ndi kusankha mapangidwe abwino kwambiri.

Zotsatirazi ndi mfundo za kapangidwe ka shaft

1. Sungani zinthu, chepetsani kulemera, ndipo gwiritsani ntchito mawonekedwe ofanana-mphamvu. Dimensional kapena lalikulu gawo coefficient cross-sectional mawonekedwe.

2, yosavuta kuyiyika molondola, kukhazikika, kusonkhanitsa, kusokoneza ndikusintha magawo omwe ali pamtunda.

3. Gwiritsani ntchito njira zosiyanasiyana zamapangidwe kuti muchepetse kupsinjika ndikuwonjezera mphamvu.

4. Zosavuta kupanga ndikuwonetsetsa kulondola.

Kugawika kwa ma shafts Mitsinje wamba imatha kugawidwa m'ma crankshafts, mikwingwirima yowongoka, mikwingwirima yosunthika, mikwingwirima yolimba, mikwingwirima yolimba, mikwingwirima yosunthika (yosinthika) kutengera mawonekedwe a shaft.

Mtsinje wowongoka ukhoza kugawidwa mowonjezereka

1 shaft, yomwe imakhala ndi mphindi yopindika komanso torque, ndipo ndiye shaft yodziwika bwino pamakina, monga ma shafts mu zochepetsera liwiro zosiyanasiyana.

2 mandrel, omwe amagwiritsidwa ntchito kuthandizira mbali zozungulira kuti azinyamula mphindi yopindika popanda kutumiza torque, kuzungulira kwa mandrel, monga chitsulo cha njanji, ndi zina zotero, mandrel ena samazungulira, monga shaft yomwe imathandizira pulley.

3 Transmission shaft, yomwe imagwiritsidwa ntchito makamaka potumiza torque popanda kupindika mphindi, monga ma optical axis mu makina osuntha a crane, shaft yagalimoto, ndi zina zambiri.

Zida za shaft makamaka zimakhala zitsulo za carbon kapena alloy zitsulo, ndi chitsulo cha ductile kapena alloy cast iron angagwiritsidwenso ntchito. Kugwira ntchito kwa shaft nthawi zambiri kumadalira mphamvu ndi kuuma kwake, ndipo kuthamanga kwakukulu kumadalira kukhazikika kwa kugwedezeka. Kugwiritsa Ntchito Kukhwimitsa Kulimba kwa shaft kumawerengeredwa ngati kuchuluka kwa kupindika kwa shaft panthawi yogwira ntchito, kuyeza motengera angle ya torsion pa mita ya kutalika kwa shaft. Kupindika kwa torsional shaft kuyenera kukhudza magwiridwe antchito ndi kulondola kwa makinawo. Mwachitsanzo, ngati mbali ya torsion ya camshaft ya injini yoyaka mkati ndi yaikulu kwambiri, idzakhudza nthawi yoyenera yotsegula ndi kutseka kwa valve; mbali ya torsion ya shaft yopatsira ya gantry crane motion motion imakhudza kulumikizana kwa gudumu loyendetsa; Kulimba kwakukulu kwa torsional kumafunika kwa ma shaft omwe ali pachiwopsezo cha kugwedezeka kwa torsional ndi shaft mu makina opangira.

Zofunikira zaukadaulo 1. Kulondola kwa makina

1) Kulondola kwapang'onopang'ono Kulondola kwa magawo a shaft makamaka kumatanthawuza kukula kwake ndi kulondola kwapang'onopang'ono kwa shaft ndi kulondola kwapang'onopang'ono kwa kutalika kwa shaft. Malinga ndi zofunikira pakugwiritsa ntchito, kulondola kwa mainchesi a magazini nthawi zambiri kumakhala IT6-IT9, ndipo magazini yolondola imafikiranso IT5. Kutalika kwa shaft nthawi zambiri kumatchulidwa ngati kukula kwadzina. Pa kutalika kwa sitepe iliyonse ya shaft yodutsa, kulolerana kungaperekedwe malinga ndi zofunikira zogwiritsira ntchito.

2) Kulondola kwa geometric Magawo a Shaft nthawi zambiri amathandizidwa ndi magazini awiri. Magazini awiriwa amatchedwanso magazini othandizira komanso ndizomwe zimafotokozera za shaft. Kuphatikiza pa kulondola kwa dimensional, kulondola kwa geometric (kuzungulira, cylindricity) kwa magazini yothandizira ndikofunikira nthawi zambiri. Kwa magazini olondola kwambiri, cholakwika cha geometry chiyenera kungokhala pakulolera kwa mainchesi. Pamene zofunikira zili pamwamba, zololera zomwe zimaloledwa ziyenera kufotokozedwa pa gawo lojambula.

3) Kulondola kwanthawi zonse Kugwirizana pakati pa magazini okweretsa (majenale a mamembala osonkhanitsidwa) m'magawo a shaft pokhudzana ndi magazini othandizira ndi chofunikira chodziwika kuti agwirizane bwino. Nthawi zambiri, shaft yolondola mwachizolowezi, kufananiza kofananira ndi kutha kwa magazini yothandizira nthawi zambiri imakhala 0.01-0.03 mm, ndipo shaft yolondola kwambiri ndi 0.001-0.005 mm. Kuonjezera apo, kulondola kwapadziko lonse ndikofanana ndi coaxiality ya mkati ndi kunja kwa cylindrical, perpendicularity ya axially positioned end faces ndi axial line, ndi zina zotero. 2, roughness pamwamba Malinga ndi kulondola kwa makina, liwiro la opareshoni, roughness kufunika kwa mbali shaft ndi osiyana. Kawirikawiri, pamwamba pa roughness Ra wa magazini yothandizira ndi 0.63-0.16 μm; pamwamba pa roughness Ra wa magazini yofananira ndi 2.5-0.63 μ m.

Tekinoloje yopangira 1, kusankha kwa magawo a shaft ya zida za shaft, makamaka kutengera mphamvu, kuuma, kukana kuvala ndi kupanga mapangidwe a shaft, ndikuyesetsa chuma.

Zomwe zimagwiritsidwa ntchito nthawi zambiri: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV| EN 1.4201 | 42CrMo4

SHAFT YOPHUNZITSIDWA

Shaft yayikulu yopangira mpaka 30 T.

●Zitsulo Zonse zili ndi luso lopanga kupanga mphete zopangidwa ndi mitundu iyi ya aloyi:

● Chitsulo chachitsulo

●Chitsulo cha carbon

●Chitsulo chosapanga dzimbiri

ZOPHUNZITSIDWA ZA SHAFT

Zakuthupi

MAX DIAMETER

MAX WIGHT

Carbon, Aloyi Zitsulo

1000 mm

20000 kgs

Chitsulo chosapanga dzimbiri

800 mm

15000 kgs

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., Monga ISO yolembetsa yovomerezeka yopangira zida, zimatsimikizira kuti forgings ndi / kapena mipiringidzo ndi yofanana mumtundu komanso yopanda anomalies yomwe imawononga makina kapena makina opangira zinthu.

Mlandu:

Kalasi yachitsuloBS EN 42CrMo4

BS EN 42CrMo4 Zogwirizana ndi Zitsulo za Alloy ndi Zofananira

| 42CrMo4/1.7225 | C | Mn | Si | P | S | Cr | Mo |

| 0.38-0.45 | 0.60-0.90 | 0.40 max | 0.035 kukula | 0.035 kukula | 0.90-1.20 | 0.15-0.30 |

| Gawo la EN 10250 | Zofunika No. | DIN | ASTM A29 | Chithunzi cha JIS G4105 | Chithunzi cha BS 970-3-1991 | Chithunzi cha BS 970-1955 | Chithunzi cha AS 1444 | AFNOR | GB |

| 42CrMo4 | 1.7225 | 38HM pa | 4140 | Chithunzi cha SCM440 | 708M40 | EN19A | 4140 | Chithunzi cha 42CD4 | 42CrMo |

Gawo lachitsulo 42CrMo4

Mapulogalamu

Malo ena ogwiritsira ntchito EN 1.4021

Zigawo za Pump- ndi ma Vavu, Shafting, Spindels, Ndodo za pisitoni, Zopangira, Stirrers, Bolts, Mtedza

TS EN 1.4021 mphete zopangira - Zopangira zitsulo zosapanga dzimbiri za mphete zowombera

Kukula: φ840 x L4050mm

Kupanga (Ntchito Yotentha) Kuchita , Njira Yochizira Kutentha

| Kupanga | 1093-1205 ℃ |

| Annealing | 778-843 ℃ ng'anjo yozizira |

| Kutentha | 399-649 ℃ |

| Normalizing | 871-898 ℃ mpweya wozizira |

| Austenize | 815-843 ℃ kuzimitsa madzi |

| Kuchepetsa Kupsinjika | 552-663 ℃ |

| Kuzimitsa | 552-663 ℃ |

DIN 42CrMo4 Alloy Steel Mechanical Properties

| Kukula Ø mm | Zokolola kupsinjika | Ultimate tensile Stress, | Elongation | Kuuma kwa HB | Kulimba mtima |

| Rp0.2,N/nn2, min. | Rm,N/n2 | A5,%, min. | KV, Joule, min. | ||

| <40 | 750 | 1000-1200 | 11 | 295-355 | 35 pa 20ºC |

| 40-95 | 650 | 900-1100 | 12 | 265-325 | 35 pa 20ºC |

| > 95 | 550 | 800-950 | 13 | 235-295 | 35 pa 20ºC |

| Rm - Mphamvu yolimba (MPa) (Q +T) | ≥635 |

| Rp0.2 0.2% mphamvu yotsimikizira (MPa) (Q +T) | ≥440 |

| KV - Mphamvu yamphamvu (J) (Q +T) | + 20 ° |

| A - Min. elongation pa fracture (%) (Q +T) | ≥20 |

| Z - Kuchepetsa gawo lapakati pa fracture (%) (N+Q +T) | ≥50 |

| Kulimba kwa Brinell (HBW): (Q +T) | ≤192HB |

ZINA ZOWONJEZERA

PEMBANI MALANGIZO LERO

Kapena Imbani: 86-21-52859349