Industry News

-

What are the forging equipment?

With the development of heavy industry, forging equipment is also diverse. Forging equipment refers to the mechanical equipment used for forming and separating in forging process. Forging equipment: 1. Forging hammer for forming 2. Mechanical press 3. Hydraulic press 4. Screw press and forging ma...Read more -

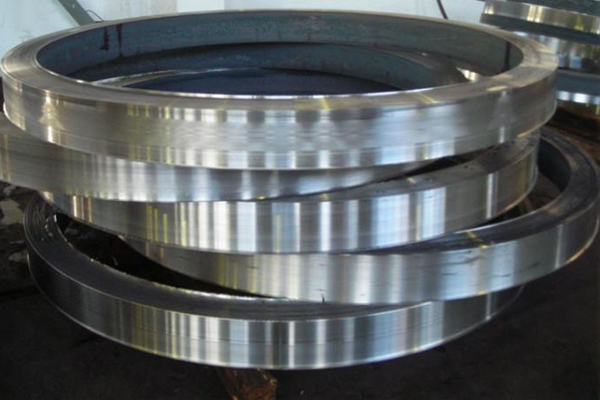

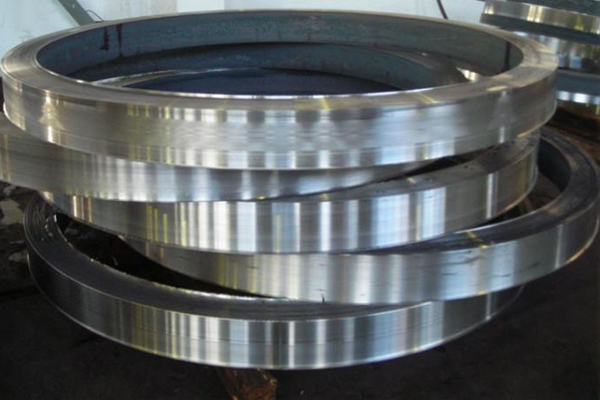

Various forging processes of large diameter flange

There are many types of large diameter flange forging process, and the flange price difference is not small. Large diameter flange forging process is as follows: 1. This process is mainly used for large diameter flanges with the required interface in the center. Although soldered, the basic finis...Read more -

Flange connection

Flange connection is to fix two pipes, pipe fittings or equipment respectively on a flange plate, and the flange pad is added between the two flanges, which is fastened together with bolts to complete the connection. Some pipe fittings and equipment have their own flanges, which are also flange c...Read more -

What should be improved in the production process of forging parts

In today's use of forging parts, if the temperature control is bad or the careless will cause a series of defects in the process of production, this will reduce the quality of the forging parts, in order to eliminate forging pieces of this defect, must be the first to improve the metal parts, in ...Read more -

Factors influencing flange use degree

In the case of common coarseness of flanges, different steel grades and different winding methods have different fatigue limit reduction degrees, such as the decrease degree of hot coil flanges is smaller than hot coil flanges. Practice shows that cadmium plating can greatly increase the fatigue ...Read more -

Cooling and heating methods for stainless steel forgings

According to the different cooling speed, there are three cooling methods of stainless steel forgings: cooling in the air, cooling speed is faster; The cooling rate is slow in lime sand. In the furnace cooling, cooling speed is slowest. 1. Cooling in the air, stainless steel forgings after forgin...Read more -

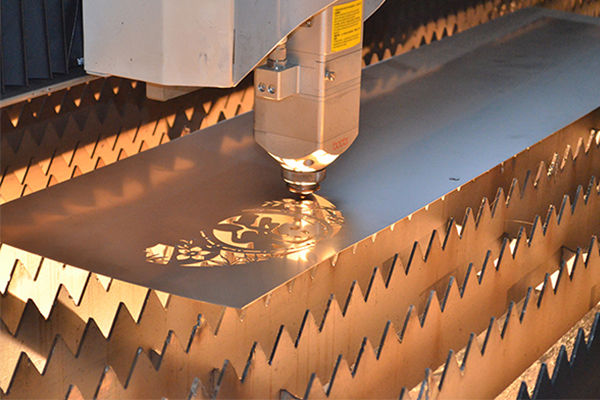

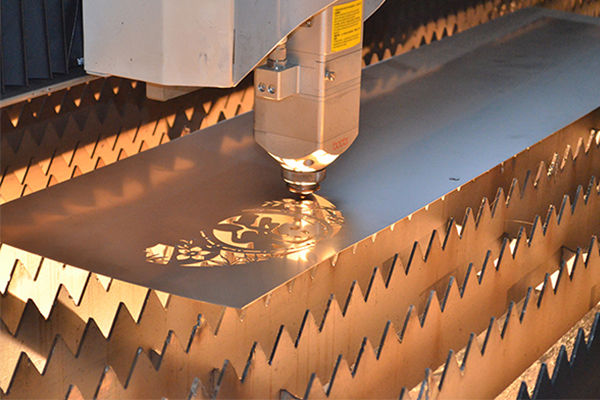

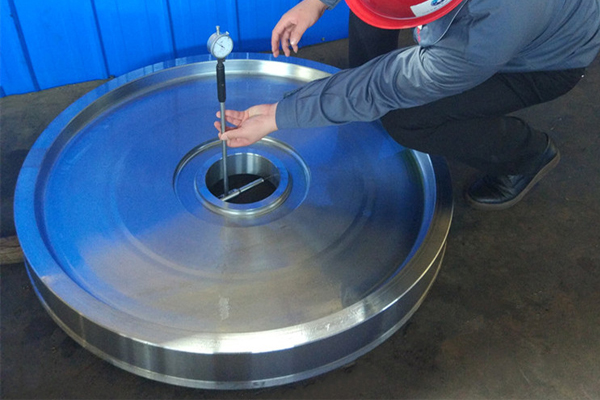

Inspection of appearance quality of forgings

Appearance quality inspection is generally a non-destructive inspection, usually with the naked eye or low magnifying glass inspection, if necessary, also use non-destructive inspection method. The inspection methods of internal quality of heavy forgings can be summarized as: macroscopic organiza...Read more -

What should we pay attention to in terms of safety during forging processing?

During the forging process, in terms of safety, we should pay attention to: 1. forging production is carried out in the state of metal burning (for example, 1250~750℃ range of low carbon steel forging temperature), because of a lot of manual labor, accidentally burning may occur. 2. The heating f...Read more -

Forging: How to forge good forgings?

Now the fittings in the industry mostly use forging way, DHDZ provides high-quality forgings, so now when forging, what raw materials are used? The forging materials are mainly carbon steel and alloy steel, followed by aluminum, magnesium, copper, titanium and their alloys. The original state of ...Read more -

What should we pay attention to in terms of safety during forging processing?

During the forging process, in terms of safety, we should pay attention to: 1. forging production is carried out in the state of metal burning (for example, 1250~750℃ range of low carbon steel forging temperature), because of a lot of manual labor, accidentally burning may occur. 2. The heating f...Read more -

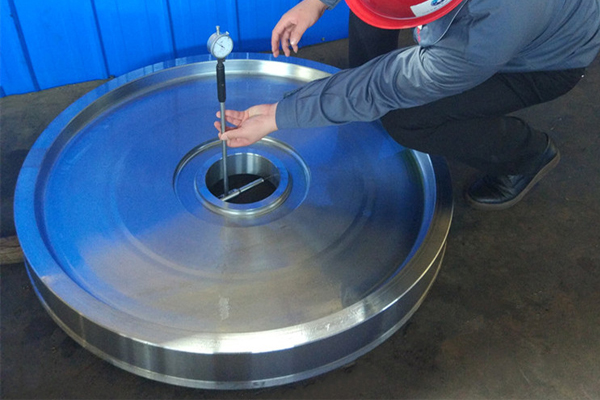

Is there a requirement for hardness of shaft forgings?

Surface hardness and uniformity of shaft forgings are the main items of technical requirements and routine inspection. The hardness of the body shows the wear resistance, etc., in production, the resilience shore D hardness value HSd is used to express. The hardness requirements of shaft forgings...Read more -

What are the quality checks for forgings?

In order to ensure the quality of forgings to meet the requirements of design and use of the indicators, it is necessary to forgings (blank, semi-finished products and finished products) quality inspection. The content of forgings quality inspection includes: chemical composition inspection, appe...Read more