Industry News

-

Installation sequence of butt welding flanges

Butt welding flange, also known as high neck flange, is a kind of pipe fitting, refers to the neck and a round pipe transition and pipe butt welding flange connection. Welding flange is not easy to deformation, good sealing, widely used, suitable for pressure or temperature fluctuation of pipelin...Read more -

How to prevent flange cracking

First of all, the cracking of stainless steel flange chemical composition analysis, analysis results indicate that the chemical composition of the stainless steel flange and welding data are in accordance with the relevant specifications. The brinell hardness of the flange neck surface and sealin...Read more -

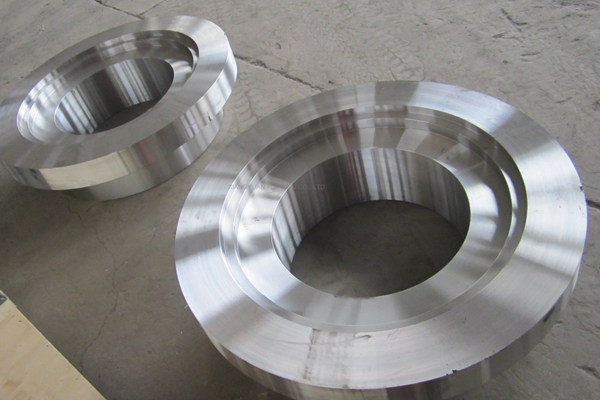

What are the analysis methods of forging quality?

The main task of forgings quality inspection and quality analysis is to identify the quality of forgings, analyze the causes of forgings defects and preventive measures, analyze the causes of forgings defects, put forward effective prevention and improvement measures, which is an important way to...Read more -

Flange manufacturer’s connection sealing treatment

There are three types of high-pressure flange sealing surface: plane sealing surface, suitable for low pressure, non-toxic media occasions; Concave and convex sealing surface, suitable for slightly higher pressure occasions; Tenon groove sealing surface, suitable for flammable, explosive, toxic m...Read more -

Does common carbon steel flange have anticorrosion function?

Flanges are also called flanges or flanges. According to the different materials, can be divided into carbon steel flange, stainless steel flange and alloy steel flange. Carbon steel flange is the flange containing carbon steel material, according to the different content of trace elements, can b...Read more -

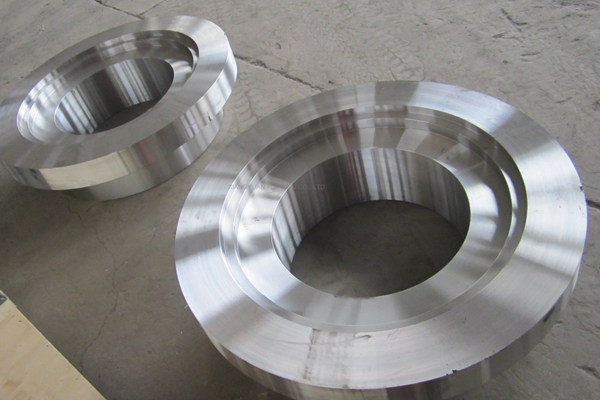

What is the use of wind power flange?

Wind turbine flange is a structural part connecting each section of tower cylinder or tower cylinder and hub, hub and blade, usually connected by bolts. Wind power flange is simply wind turbine flange. Wind power flange is also called tower flange, its process mainly has the following steps: 1. r...Read more -

Internal quality inspection of stainless steel forgings

Because stainless steel forgings are often used in the key position of the machine, so the internal quality of stainless steel forgings is very important. Because the internal quality of stainless steel forgings can not be tested by intuitive method, so special physical and chemical inspection me...Read more -

Alloy flange manufacturers: stainless steel flange rust spot how to deal with

Alloy flange manufacturer: generally supporting in water supply and drainage accessories (common on the expansion joint), the factory has a piece of flange at both ends of the expansion joint, directly connected with the pipeline and equipment in the project with bolts. That is, the kind of flang...Read more -

Flange basic use of common sense summary

To assemble a flat-welded flange, insert the pipe end into 2/3 of the inner diameter of the flange and spot weld the flange to the pipe. If it is a degree tube, spot weld from above, then check the position of the calibration flange from different directions using a 90° square and convert the sea...Read more -

Flange connection quality requirements

Flange selection must meet the design requirements. When the design does not require, should be in accordance with the system of high working pressure, high working temperature, working medium, flange material grade and other factors comprehensive selection of appropriate form and specifications ...Read more -

How to avoid oxidation problems of forging parts

Due to the forging parts is produced by forging process, so the forging can be divided into hot forging and cold forging, hot forging is above the metal recrystallization temperature forging, raise the temperature can improve the plasticity of metal, improve the immanent quality of workpiece, mak...Read more -

Free forgings production forgings several points for attention

The tools and equipment used for free forging are simple, universal and low cost. Compared with casting blank, free forging eliminates shrinkage cavity, shrinkage porosity, porosity and other defects, so that the blank has higher mechanical properties. Forgings are simple in shape and flexible in...Read more