Industry News

-

Analysis of butt welding flange production process

1, butt welding flange annealing temperature is up to the specified temperature, butt welding flange treatment is generally taken solution heat treatment, that is, people usually so-called "annealing", the temperature range is 1040~1120℃. You can also observe through the annealing furnace observa...Read more -

Rust removal tool for stainless steel flange

1. file: flat, triangular and other shapes, mainly used to remove welding slag and other prominent hard objects. 2. Wire brush: it is divided into long handle and short handle. The end face of the brush is made of thin steel wire, which is used to remove the rust and residue left after scraping b...Read more -

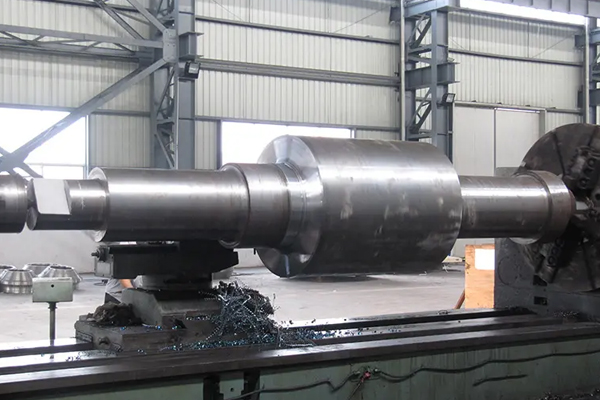

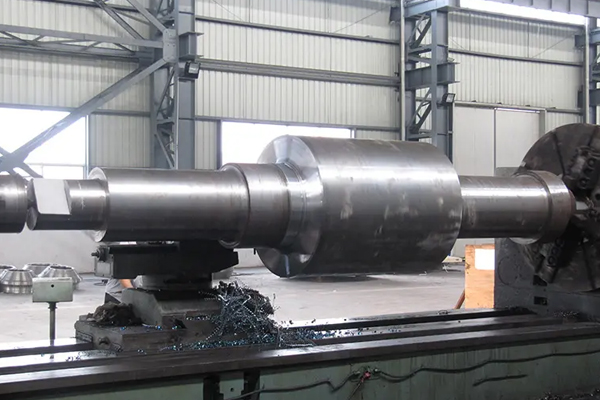

Forging flange production process

The forging process usually includes the following steps: selection of high quality billet blanking, heating, forming and forging cooling. Forging processes include free forging, die forging and thin film forging. During production, different forging methods are selected according to the quality ...Read more -

Flange connection and process flow

1. Flat welding: only welding the outer layer, do not need to weld the inner layer; Generally used in medium and low pressure pipelines, the nominal pressure of pipe fittings should be less than 2.5mpa. There are three kinds of sealing surface of flat welding flange, respectively smooth type, con...Read more -

Application of carbon steel flange in making steel plate

Carbon steel flange itself compact structure, simple structure, maintenance is also very convenient, sealing surface and spherical surface is often in a closed state, not easy to be washed by the medium, easy operation and maintenance, suitable for solvents, acid, water and natural gas and other ...Read more -

China gb neck flange manufacturer – quality win

DHDZ is the national standard with neck flange manufacturers. The company has strong technical force, can design and manufacture various special specifications of pipe fitting products according to user requirements. With metallographic inspection, physical experiment, chemical analysis, non-dest...Read more -

How to identify flange quality

Shop around. How do you compare? Just comparing prices? Can you guarantee the quality of the flange you buy? The following flange manufacturer teaches you how to identify the quality of the flange. In order to buy more cost-effective flange products. 1. Price comparison, when much lower than the ...Read more -

Stainless steel flange and carbon steel flange material how to identify

Stainless steel flange and carbon steel flange material how to identify? How to distinguish the roughly material of two kinds of flanges is relatively simple. The following DHDZ flange manufacturer takes you to simply understand the simple way to distinguish the material of two kinds of products....Read more -

What are the four factors that affect the flange process

Four factors affecting the flange process are: 1. Annealing temperature reaches the specified temperature. Flange processing is generally adopted solution heat treatment, temperature range of 1040~1120℃ (Japanese standard). You can also observe through the annealing furnace observation hole, the ...Read more -

What problems will be encountered in the forging process

Forging processing process may encounter a variety of problems, we will introduce in detail. One, aluminum alloy oxide film: The oxide film of aluminum alloy is usually located on the die forged web, near the parting surface. The surface of the fracture has two characteristics: first, it is flat ...Read more -

Surface heat treatment of steel

⑴ Surface quenching: Is the surface of the steel through rapid heating to the critical temperature above, but the heat has not had time to spread to the core before the rapid cooling, so that the surface layer can be quenched in martensitic tissue, and the core has not undergone phase transformat...Read more -

What are the advantages of forgings and why do we choose forgings?

Forgings belong to the building materials industry, its use is more widely, from the concept of: forgings is the metal is applied pressure, through plastic deformation to shape the required shape or the appropriate compression force of the object. Forging is the use of the forging equipment to th...Read more