Industry News

-

How to check forging raw materials

Forgings before forging processing, need to go through a procedure, have to test the quality of its raw materials, to ensure that the raw materials have no quality problems before the next process, now we will look at what requirements it has. 一. General requirements for forging raw materials. 1...Read more -

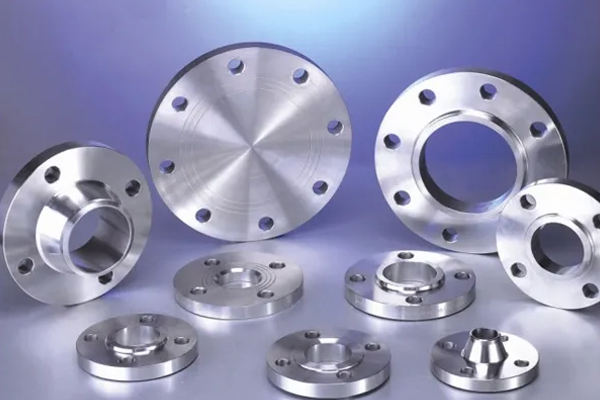

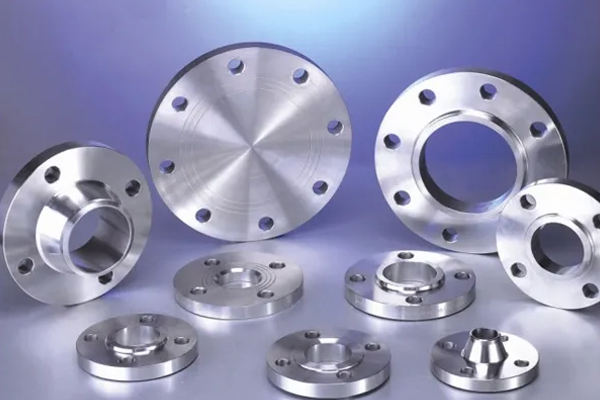

The advantages of stainless steel flanges are introduced

(1) Stainless steel flanges have low hardness and good toughness data, such as low carbon steel and aluminum alloy. It has low hardness and good toughness. It is difficult to cut chips and easy to form chips during cutting, which affects the quality of the surface. Therefore, stainless steel flan...Read more -

What is the cause of flange leakage?

What is the cause of flange leakage? French factory staff summarized the following seven leakage reasons, hoping to help friends in need. 1, flange leakage reason: wrong mouth A staggered joint is where the pipe and flange are perpendicular, but the two flanges are not concentric. The flange is n...Read more -

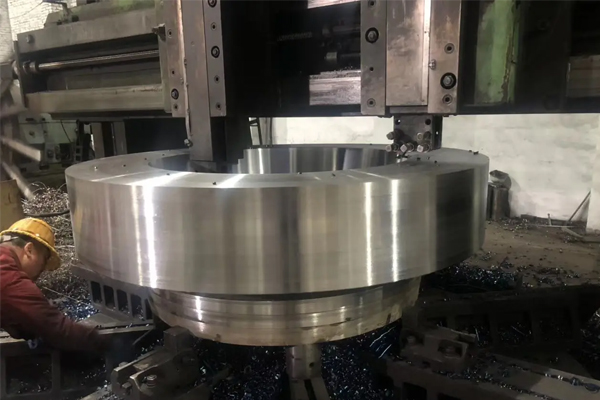

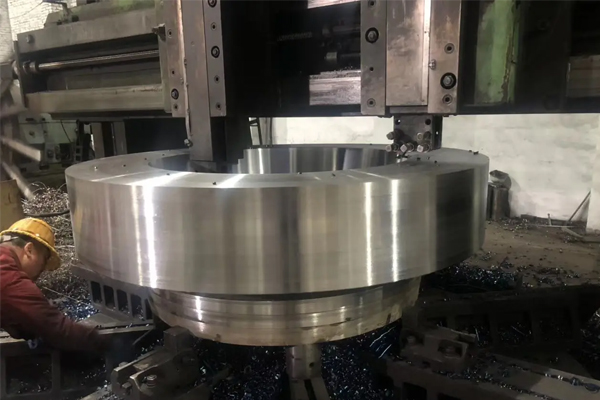

Stainless steel flange die forging equipment and application characteristics

The mechanical properties of the forgings are higher than those produced on the hammer. High productivity; Less metal loss; Hammer forging die is composed of two parts of the upper and lower die, horizontal machine is composed of punch and by two half of the composite of a total of three parts of...Read more -

What are the uses of forgings?

Forgings are workpiece or blank obtained by forging deformation of metal billets. The mechanical properties of metal billets can be changed by applying pressure to produce plastic deformation. Forgings can be divided into cold forging warm forging and hot forging according to the temperature of t...Read more -

Forging stamping production technology characteristics

Stamping is one of the basic methods of metal plastic processing. It is mainly used for processing sheet forgings, so it is often called sheet stamping. Because this method is carried out at room temperature, it is also called cold stamping. Although the above two names are not very precise stamp...Read more -

How to identify the quality of forging

The main task of forgings quality inspection and quality analysis is to identify the quality of forgings, analyze the causes of forgings defects and preventive measures, analyze the causes of forgings defects, put forward effective prevention and improvement measures, which is an important way to...Read more -

There are three types of flange sealing surfaces

The part that connects the pipe to the pipe is connected to the pipe end. There are holes in the flange and bolts hold the two flanges together. Gasket seals between flanges. Flanged pipe fittings refer to pipe fittings with flanges (flanges or joints). It may be cast, threaded or welded. The fla...Read more -

Standard system for flange

The international pipe flange standard mainly has two systems, namely the European pipe flange system represented by German DIN (including the former Soviet Union) and the American pipe flange system represented by American ANSI pipe flange. In addition, there are Japanese JIS pipe flanges, but i...Read more -

Knowledge of flange blanks

Flange blank, flange blank is a more common form of production at present, liaocheng development zone hongxiang stamping parts factory compared with the traditional flange production process, has the following obvious advantages 1) raw materials according to customer demand all using standard ma...Read more -

Specification for heating ingot steel used in forging

Large free forgings and high alloy steel forgings are mainly made of steel ingot, which can be divided into large ingot and small ingot according to the specification of steel ingot. Generally the mass is greater than 2t ~ 2.5t, diameter is greater than 500mm ~ 550mm ingot called large ingot, oth...Read more -

Butt-welding flange sealing is reliable

High pressure butt welding flange is one of the most demanding flange products in the market. The general pressure grade of high-pressure butt welding flange is between 0.5MPA-50mpa. The structural form of high-pressure butt welding flange is divided into unit flange, integral flange, and insulat...Read more