Industry News

-

The difference between WN and SO Flange

SO flange is an inner hole machined slightly larger than the outside diameter of the pipe, the pipe inserted in the welding.Butt welding flange is the end of the pipe diameter and wall thickness of the same as the pipe to be welded, welding the same as the two pipes. SO and butt welding refers to...Read more -

The Precision Forging Advantage

Precision forging normally means close-to-final form or close-tolerance forging. It is not a special technology, but a refinement of existing techniques to a point where the forged part can be used parts2cmykwith little or no subsequent machining. Improvements cover not only the forging method it...Read more -

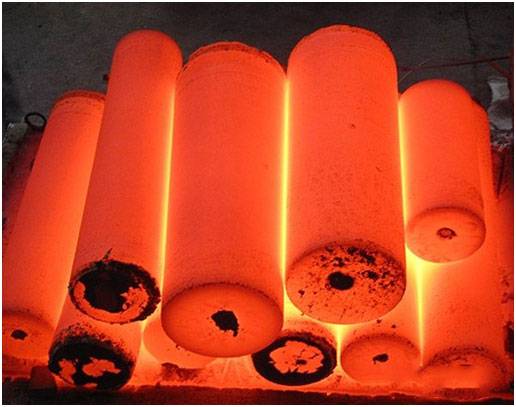

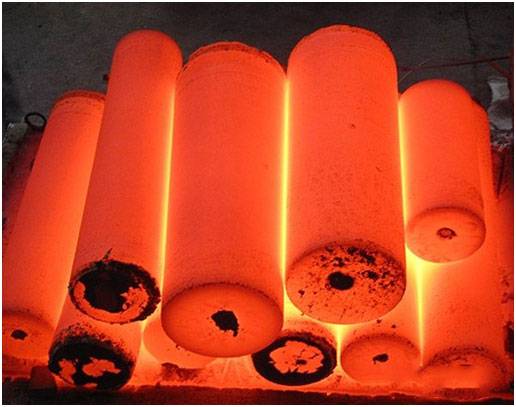

50 c8 Ring -Forging quenching.

The ring is Quenching + tempering. The forged-ring is heated to an appropriate temperature (quenching temperature 850℃, tempering temperature 590℃)and kept for a period of time, and then immersed in the medium to quickly cool down. https://www.shdhforging.com/uploads/Forging-quenching.mp4 50 c8 ...Read more -

how are forgings produced

Forging--metal shaping by plastic deformation--spans a myriad of equipment and techniques. Knowing the various forging operations and the characteristic metal flow each produces is key to understanding forging design. Hammer and Press Forging Generally, forged components are shaped either by a ha...Read more -

Hydraulic presses for forging ring blanks

The first forging operation when manufacturing seamless rings is forging ring blanks. Ring rolling lines turn these into the precursors for bearing shells, crown gears, flanges, turbine disks for jet engines and various highly stressed structural elements. Hydraulic presses are particularly well ...Read more -

168 Forging mesh: What are the principles and methods of forging die renovation?

In forging die work, if the main parts of forging die are found to be too badly damaged to be repaired randomly, the forging die should be removed and repaired by the die maintainer. 1.The principles of renovation are as follows: (1) Die parts exchange or part update, must meet the forging die de...Read more -

What should be noticed before forging heat treatment?

The inspection of forgings before heat treatment is the pre-inspection procedure for the finished products specified in the forging drawings and process CARDS after the completion of the forging process, including their surface quality, appearance dimension and technical conditions.Shellfish insp...Read more -

RAISED FACE FLANGE (RF)

A raised face flange (RF) is easy to recognize as the gasket surface area is positioned above the bolting line of the flange. A raised face flange is compatible with a wide range of flange gaskets, ranging from flat to semi-metallic and metallic types (as, for example, jacketed gaskets and spiral...Read more -

flange designs

Commonly used flange designs have a soft gasket squeezed between harder flange surfaces to form a leak-free seal. The various gasket materials are rubbers, elastomers (springy polymers), soft polymers covering a springy metal (e.g., PTFE covered stainless steel), and soft metal (copper or aluminu...Read more -

Flange seals provide the front-face static sealing function within flange connections.

Flange seals provide the front-face static sealing function within flange connections. There are two major design principles available, either for internal or external pressure. Various designs in a broad range of compounds provide individual features. flange seals offer enhanced sealing performa...Read more -

Knowledge of machining forged circle

Forging circle belongs to a kind of forgings, in fact, to put it simply, it is the forging of round steel. Forged circles are obviously different from other steel in industry, and forged circles can be divided into three categories, but many people do not have a special understanding of forged ci...Read more -

Changes in microstructure and properties of forgings during tempering

Forgings after quenching, martensite and retained austenite is unstable, they have a spontaneous organization transformation trend to stability, such as the supersaturated carbon in martensite to precipitate residual austenite decomposition in order to promote the shift, such as for tempering tem...Read more