Industry News

-

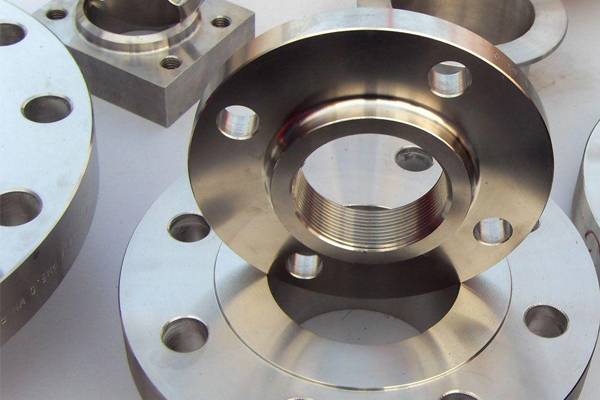

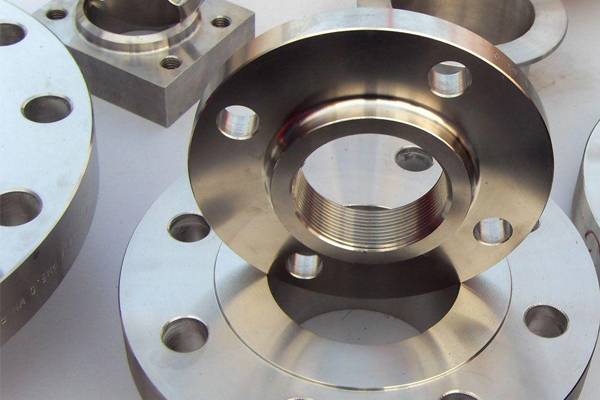

Detailed classification of commonly used flanges in China

1. According to the standard of mechanical industry, flange types are: plate type flat-welded flange, butt-welded flange, integral flange, butt-welded ring-plate type loose sleeve flange, flat-welded ring-plate type loose sleeve flange, flanged ring-plate type loose sleeve flange, flange cover. 2...Read more -

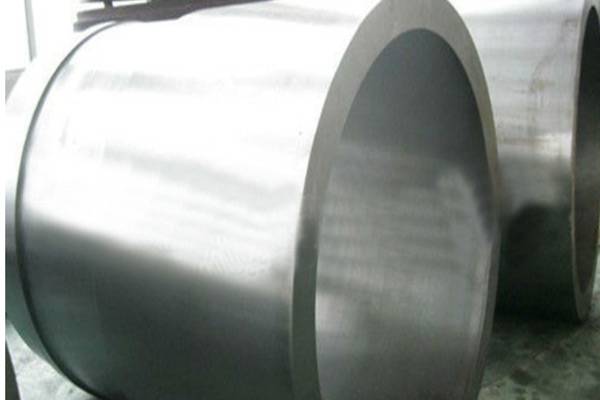

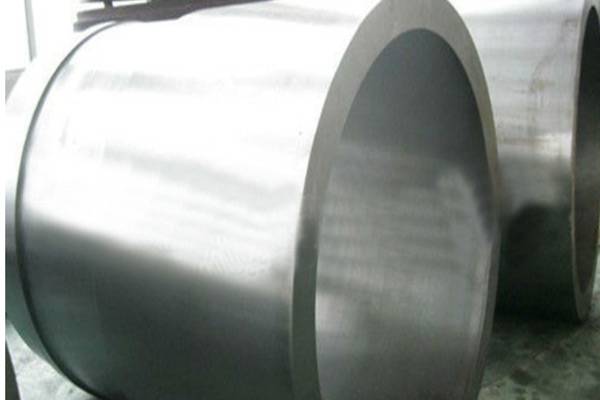

What kind of shaft forgings meet the requirements?

Axial forging is a kind of wide application of forgings, such as axial plus has good processability, m any porosity in practice, there is no other flaws, thus not only has good appearance, with fine, here is how to introduce you to conform to the requirements of axial forgings to be popular. Firs...Read more -

The sealing method of hydraulic cylinder forging

The reason why the hydraulic cylinder forgings need to be sealed is because of the existence of internal leakage and external leakage. When there is internal leakage and external leakage in the hydraulic cylinder, it will lead to the volume of the hydraulic cylinder's cavity and the efficiency wi...Read more -

What forging technology does the flange factory have?

Flange factory is a production enterprise producing flanges. Flanges are parts connected between pipes, which are used for the connection between pipe ends. It is also useful for the flange on the inlet and outlet of the equipment for the connection between two devices. The production technology ...Read more -

How to forge stainless steel forgings?

The precision of rough or stainless steel forgings is higher. The application of advanced technology and equipment can achieve little or no cutting. The metal materials used in forging should have good plasticity, so that under the action of external force, plastic deformation can be produced wit...Read more -

The sealing principle and characteristics of flange

Sealing of flat-welded flanges has always been a hot issue related to the production cost or economic benefit of enterprises. However, the main design disadvantage of flat-welded flanges is that they are not leakproof. This is a design flaw: the connection is dynamic, and periodic loads, such as ...Read more -

What should be noted in the examination of die forgings before heat treatment?

The inspection before solution heat treatment is a pre-inspection procedure to check the finished product's surface quality and dimensions according to the technical conditions, die forging drawing and process card after the forging forming process is finished. Specific inspection should pay atte...Read more -

How to find the processing difficulties of stainless steel flange

First of all, before choosing the drill bit, take a look at the difficulties in stainless steel flange processing. Find out the difficulty can be very accurate, very fast to find the use of the drill. What are the difficulties in stainless steel flange processing? Sticky knife: stainless steel pr...Read more -

What is the process of forging?

1. Isothermal forging is to keep the temperature of billet constant during the whole forming process. Isothermal forging is used to take advantage of the high plasticity of certain metals at constant temperature or to obtain specific structures and properties. Isothermal forging requires the mold...Read more -

The main disadvantages of water as a quenching cooling medium for forgings ?

1) in the austenite isothermal transformation diagram of the typical area, that is, about 500-600℃, water in the steam film stage, the cooling rate is not fast enough, often cause uneven cooling and insufficient cooling speed forgings and the formation of the "soft point".In the martensite transf...Read more -

What kind of bolt connection does stainless steel flange use?

Customers often ask: stainless steel flange connection whether to choose stainless steel bolts? Now I will write what I have learned to share with you: Material has nothing to do with the material of flange bolts, according to the European system HG20613-97 "steel pipe flange with fasteners (the...Read more -

How to use welding flange correctly

Flanges With the rapid development of domestic foreign minister pipeline construction, pipeline pressure test has become an essential important link, before and after the pressure test, must pass the ball sweep line for each section of the pipeline, the number of times is generally 4~5. Especiall...Read more