Industry News

-

Three elements of heat treatment for forgings

1. Size effect: The mechanical properties of forged steel vary with its shape and size. Generally, the larger the size, the shallower the quenching depth and the lower the mechanical properties of the heat treatment in the same cooling medium. 2. Mass Effect Refers to the quality (weight) of the ...Read more -

What are the main disadvantages of water as a quenching cooling medium for forgings?

1) in the austenite isothermal transformation map of the typical area, that is, about 500-600℃, water in the steam film stage, cooling speed is not fast enough, often cause uneven forging cooling and insufficient cooling speed and the formation of the "soft point". In the martensite transformatio...Read more -

Flat – welded flanges and butt-welded flanges

The difference in structure between neck flat welding flanges and neck butt welding flanges lies in the different connection modes of the nooks and flanges. Neck flat welding flanges are generally nooks and flanges Angle connection, while neck butt welding flanges are flanges and nooks butt conne...Read more -

What are the causes of flange leakage?

The reasons for flange leakage are as follows: 1. Deflection, refers to the pipe and flange are not vertical, different center, flange surface is not parallel. When the internal medium pressure exceeds the load pressure of the gasket, flange leakage will occur. This situation is mainly caused in ...Read more -

How is the sealing effect of the flange

Carbon steel flange, namely the body material is carbon steel flange or end flange connector. Which contains carbon steel flange, known as carbon steel flange. Common material is cast carbon steel grade WCB, forging A105, or Q235B, A3, 10#, #20 steel, 16 manganese, 45 steel, Q345B and so on. Ther...Read more -

Frequent problems in stainless steel flange processing

The processing of stainless steel flange needs to understand and pay attention to the following problems: 1, weld defects: stainless steel flange weld defects are more serious, if it is to use manual mechanical grinding treatment method to make up, then the grinding marks, resulting in uneven sur...Read more -

What are the grade requirements for butt-welded flanges

Butt-welding flange is the pipe diameter and wall thickness of the interface end are the same as the pipe to be welded, and the two pipes are welded as well. Butt-welding flange connection is easy to use, can withstand relatively large pressure. For butt-welded flanges, the materials are not the ...Read more -

DHDZ:What are the annealing processes for forgings?

The annealing process of forgings can be divided into complete annealing, incomplete annealing, spheroidizing annealing, diffusion annealing (homogenizing annealing), isothermal annealing, de-stress annealing and recrystallization annealing according to the composition, requirements and purpose o...Read more -

The eight major properties of forging

Forgings are generally forged after forging, cutting, heat treatment and other procedures. In order to ensure the manufacturing quality of the die and reduce the production cost, the material should have good malleability, machinability, hardenability, hardenability and grindability; It should al...Read more -

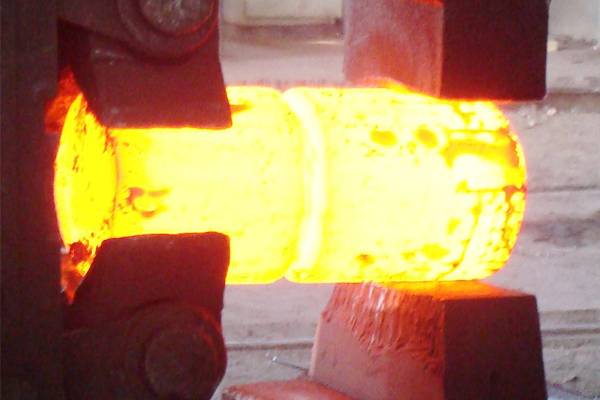

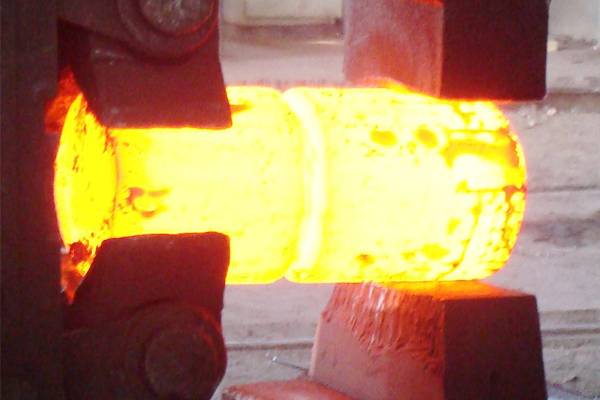

How many heating methods do you know about forgings before forging?

Preforging heating is an important link in the whole forging process, which has a direct influence on improving forging productivity, ensuring forging quality and reducing energy consumption. The proper choice of heating temperature can make the billet forming in a better plasticity state. Forgin...Read more -

Cooling and heating methods for stainless steel forgings

According to the different cooling speed, there are three cooling methods of stainless steel forgings: cooling in the air, cooling speed is faster; The cooling speed is slow in the sand; Cooling in the furnace, cooling rate is the slowest. 1. Cooling in the air. After forging, stainless steel for...Read more -

Knowledge of machining and forging round

Forging round belongs to a kind of forgings, in fact, a simple point is the round steel forging processing. Forging round has obvious difference with other steel industry, and forging round can be divided into three categories, but many people do not know about forging round, so let's understand ...Read more