Industry News

-

Details to note when using threaded flanges

Threaded flange refers to a flange connected by thread and pipe. During design, it can be handled according to loose flange. The advantage is that no welding is required, and the additional torque produced by the flange deformation on the cylinder or pipe is very small. The disadvantage is that t...Read more -

Why do you choose 304 butt welded stainless steel flanges

Let's start with a fact: Austenitic stainless steel pipes are commonly used in a variety of corrosive environments. However, if you are careful, you will find that in the design documents of some units, as long as DN≤40, all kinds of materials are basically adopted. In the design documents of oth...Read more -

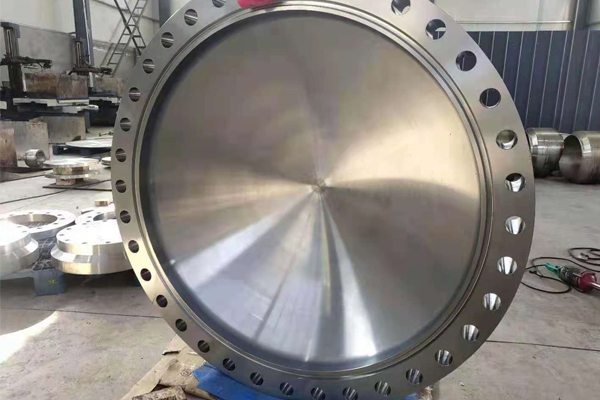

How to identify the quality of forging

The main task of forgings quality inspection and quality analysis is to identify the quality of forgings, analyze the causes of forgings defects and preventive measures, analysis and research It is an important way to improve and guarantee the quality of forgings to investigate the causes of defe...Read more -

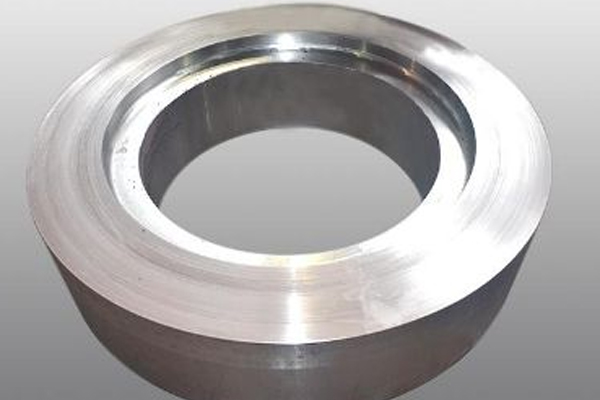

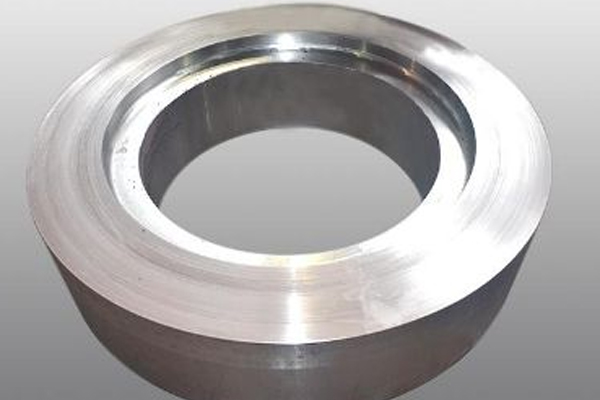

Three methods of carbon steel flange sealing

There are three types of carbon steel flange sealing surface, which are: 1, tenon sealing surface: suitable for flammable, explosive, toxic media and high pressure occasions. 2, plane sealing surface: suitable for pressure is not high, non-toxic medium occasions. 3, concave and convex sealing sur...Read more -

Do you know the four fires of heat treatment in forging technology?

Forgings in the forging process, heat treatment is the most important link, heat treatment roughly annealing, normalizing, quenching and tempering four basic processes, commonly known as metal heat treatment of the "four fire". one, metal heat treatment of the fire - annealing: 1, annealing is t...Read more -

Factors affecting oxidation of forgings

The oxidation of forgings is mainly affected by the chemical composition of the heated metal and the internal and external factors of the heating ring (such as furnace gas composition, heating temperature, etc.). 1) Chemical composition of metal materials The amount of oxide scale formed is close...Read more -

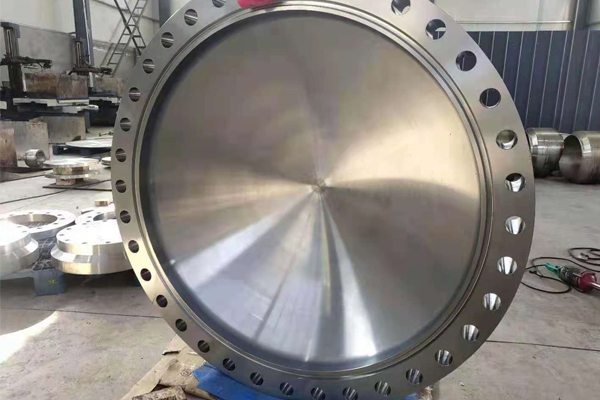

Methods for inspection of large forgings

Due to the high cost of raw materials for large forgings, as well as the production process, if defects occur, they will affect the follow-up processing or poor processing quality, and some affect the performance and use of forgings strictly, even reducing the service life of the finished parts, ...Read more -

Injection molding of stainless steel flanges

Stainless steel flanged ball valve, globe valve, gate valve when used, only for fully open or closed, do not allow to do flow regulation, so as to avoid sealing surface erosion, accelerated wear. Gate valves and upper screw globe valves have reverse sealing device, hand wheel to the top to the us...Read more -

What’s different killed steel and Rimmed steel!!!

Killed steel is steel that has been completely deoxidized by the addition of an agent before casting such that there is practically no evolution of gas during solidification. It is characterized by a high degree of chemical homogeneity and freedom from gas porosities. Semi-killed steel i...Read more -

How is the flange welded?

1. Flat welding: only welding the outer layer, without welding the inner layer; Generally used in medium and low pressure pipelines, the nominal pressure of the pipeline is less than 0.25mpa. There are three kinds of sealing surface of flat welding flange, which are smooth type, concave and conve...Read more -

There are problems in the processing of stainless steel forgings

Weld defects: weld defects are serious, manual mechanical grinding processing method is used to compensate, resulting in grinding marks, resulting in uneven surface, affect the appearance. Inconsistent surface: only pickling and passivation of the weld will cause uneven surface and affect the app...Read more -

The reason of sliding or crawling of hydraulic cylinder piston and the treatment method

Hydraulic cylinder piston sliding or crawling will make the hydraulic cylinder work instability. Do you know the reason for it? Do you know what to do with it? The following article is mainly for you to talk about. (1) hydraulic cylinder internal astringency. Improper assembly of the internal par...Read more