In the field of pipeline engineering, flanges, as key components for connecting pipelines, have a wide variety of types and functions. Among them, butt welded flanges have become the "star products" in industrial pipeline systems due to their excellent performance and wide application scenarios.

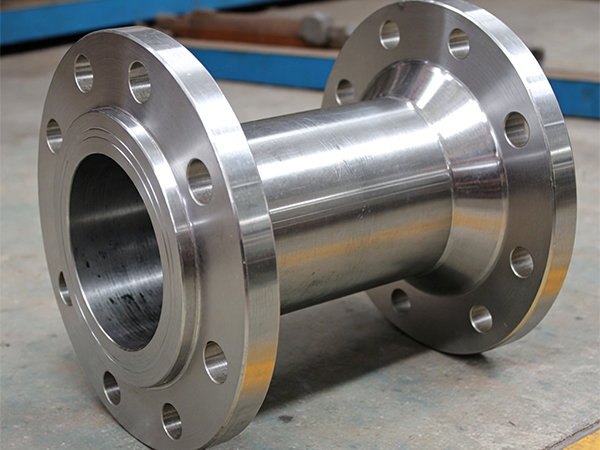

Welding flange, also known as high neck flange, is unique in that a long and inclined high neck extends from the welding point between the flange and the pipe (as shown in the schematic diagram). The clever design of this high neck not only enhances the rigidity and strength of the flange, but also effectively alleviates stress discontinuities, ensuring the stability and sealing of the flange in high-pressure, high-temperature, or low-temperature environments. The inner hole design is slightly larger than the outer diameter of the pipeline, making it easier for butt welding, while the circumferential weld seam spans both the inside and outside of the flange, further enhancing the sealing performance.

Due to these design advantages, butt welded flanges are particularly suitable for high-pressure, high-temperature, or low-temperature pipeline systems in industrial fields such as petroleum, chemical, and shipbuilding. It can withstand severe fluctuations in pressure and temperature, ensuring the stable operation of the pipeline. Meanwhile, butt welded flanges are also commonly used in pipelines for transporting flammable, explosive, or toxic media, and their reliable sealing performance provides strong guarantees for the safe transportation of the media.

In terms of manufacturing standards, butt welded flanges must comply with strict requirements such as JB4726-4728. According to the different nominal pressures and materials, the forging grades range from Grade I to Grade III to ensure the performance of the flange in different working environments. In addition, the outer slope of the neck of the welded flange should not exceed 70 °. This design detail helps to strictly control technical parameters during production and welding processes, fully utilizing the role and value of the flange.

Post time: Mar-25-2025