The sealing problem of flat welded flange has always been a hot issue related to the production cost or economic benefit of enterprises, so the sealing principle of flat welded flange has been improved and improved.However, the main design shortcoming of flat welded flange is that it cannot prevent leakage.This is a design flaw: the connection is dynamic, and periodic loads, such as thermal expansion and fluctuating loads, can cause the flange faces to move each other, affecting the function of the flange, thereby compromising the integrity of the flange and ultimately leading to leakage.

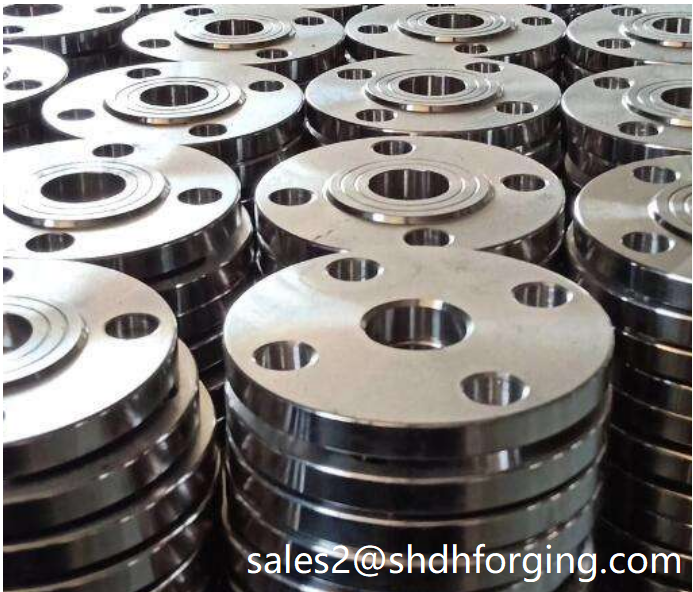

Any product is impossible to have no defects, but try to control the defects of the product to the minimum, so the company in the production of flat welding flange as much as possible to improve the performance of the product, play the greatest role.Characteristics of flat welding flange: flat welding flange not only save space, reduce weight, and ensure that the joints without leakage, good sealing performance.By reducing the sealing diameter, the size of the compact flange is reduced and the sealing section is reduced.

Next, replace the flange gasket with a sealing ring to ensure that the sealing surface matches the sealing surface.In this way, only a small amount of pressure is needed to tighten the sealing surface.As the required pressure is reduced, the size and number of the bolt is less, so we design a small volume, light weight of the new product, can reduce the weight of the traditional flange ー 70% 80%. Therefore, flat welding flange is a flange products is high quality, reduces the quality and space, and played an important role in industry application.

Sealing principle of flat welded flange: the two sealing faces of the bolt squeeze flange gasket to form a seal, but this can also cause seal damage.In order to keep the seal, you must maintain a large bolt force, and in order to do this, you must make the bolt larger.The larger bolt matches the larger nut, which means a larger bolt diameter is needed to create conditions for tightening the nut.However, the larger the diameter of the bolt, the bent flange will occur, the only way is to increase the flange part of the wall thickness.

The sealing problem of flat welded flange has always been a hot issue related to the production cost or economic benefit of enterprises, so the sealing principle of flat welded flange has been improved and improved.However, the main design shortcoming of flat welded flange is that it cannot prevent leakage.This is a design flaw: the connection is dynamic, and periodic loads, such as thermal expansion and fluctuating loads, can cause the flange faces to move each other, affecting the function of the flange, thereby compromising the integrity of the flange and ultimately leading to leakage.

Any product is impossible to have no defects, but try to control the defects of the product to the minimum, so the company in the production of flat welding flange as much as possible to improve the performance of the product, play the greatest role.Characteristics of flat welding flange: flat welding flange not only save space, reduce weight, and ensure that the joints without leakage, good sealing performance.By reducing the sealing diameter, the size of the compact flange is reduced and the sealing section is reduced.

Next, replace the flange gasket with a sealing ring to ensure that the sealing surface matches the sealing surface.In this way, only a small amount of pressure is needed to tighten the sealing surface.As the required pressure is reduced, the size and number of the bolt is less, so we design a small volume, light weight of the new product, can reduce the weight of the traditional flange ー 70% 80%. Therefore, flat welding flange is a flange products is high quality, reduces the quality and space, and played an important role in industry application.

Sealing principle of flat welded flange: the two sealing faces of the bolt squeeze flange gasket to form a seal, but this can also cause seal damage.In order to keep the seal, you must maintain a large bolt force, and in order to do this, you must make the bolt larger.The larger bolt matches the larger nut, which means a larger bolt diameter is needed to create conditions for tightening the nut.However, the larger the diameter of the bolt, the bent flange will occur, the only way is to increase the flange part of the wall thickness.

From:168 forgings net

Post time: Apr-20-2020