News

-

How to dehydrogen annealing forgings

Post-forging heat treatment of large forgings after forging forming, immediately after the heat treatment is called post-forging heat treatment. The purpose of post-forging heat treatment of large ...Read more -

What are the advantages and disadvantages of free forging classification?

One. Introduction to free forging Free forging is a forging method that makes the metal between the upper and lower anvil iron produce plastic deformation under the action of impact force or pressu...Read more -

The principle of forging blank selection

Forging blank processing is a process of forging production, forging blank quality, productivity level, will have an important impact on forging quality, performance, life and economic benefits of ...Read more -

Forging processing characteristics of forging products

Forging plant forging products are plastic deformation through forging processing, forging processing is the use of external force to produce plastic deformation of forging raw materials, forging s...Read more -

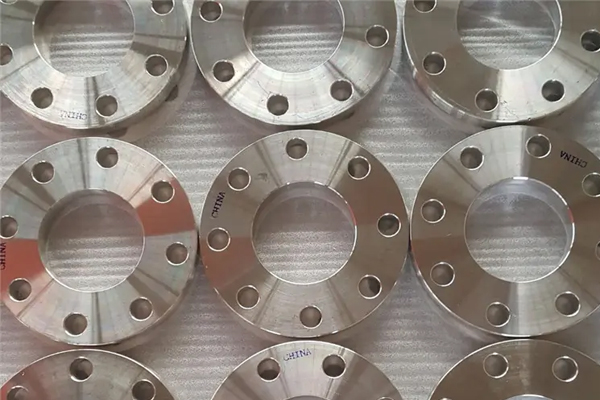

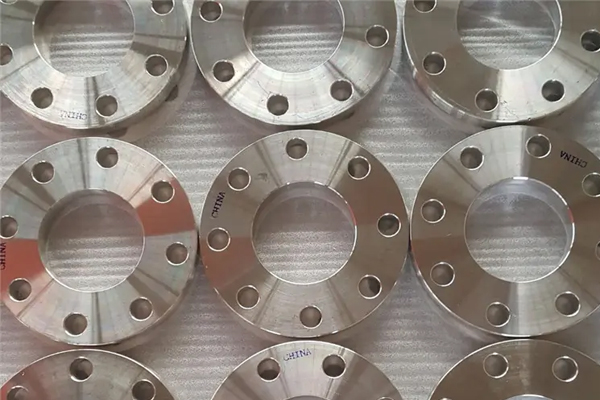

Value and mechanical properties of carbon steel flange

Carbon steel flange refers to the mechanical properties of the carbon content of the steel, and generally do not add a lot of alloy elements of steel, sometimes also known as plain carbon steel or ...Read more -

TUBE & WIRE to be held in Düsseldorf, Germany from JUNE 20-24, 2022.

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD. will be attending Wire & Tube 2022 – International Wire and Tube Trade Fair. –TUBE & WIRE to be held in Düsseldorf, Germany from J...Read more -

Flat welding flange forging method and matters needing attention

Flat welding flange according to your favorite forging die movement, it can be divided into swing rolling, swing rotary forging, roll forging, wedge rolling, ring rolling, cross rolling and so on. ...Read more -

The principle of forging blank selection

Forging blank processing is a process of forging production, forging blank quality, productivity level, will have an important impact on forging quality, performance, life and economic benefits of ...Read more -

Large caliber stainless steel flange how much?

Large diameter stainless steel flange with simple maintenance, easy maintenance, excellent material, connection is not easy to deformation characteristics, is a kind of very popular with the custom...Read more -

How to check forging raw materials

Forgings before forging processing, need to go through a procedure, have to test the quality of its raw materials, to ensure that the raw materials have no quality problems before the next process,...Read more -

The advantages of stainless steel flanges are introduced

(1) Stainless steel flanges have low hardness and good toughness data, such as low carbon steel and aluminum alloy. It has low hardness and good toughness. It is difficult to cut chips and easy to ...Read more -

What is the cause of flange leakage?

What is the cause of flange leakage? French factory staff summarized the following seven leakage reasons, hoping to help friends in need. 1, flange leakage reason: wrong mouth A staggered joint is ...Read more