News

-

DHDZ forging 2020 year-end review meeting and 2021 welcome party for freshmen

2020 is an extraordinary year, the outbreak of the epidemic, the whole country is difficult, big state organs and some enterprises, small to every employee and ordinary people, all bear a huge test...Read more -

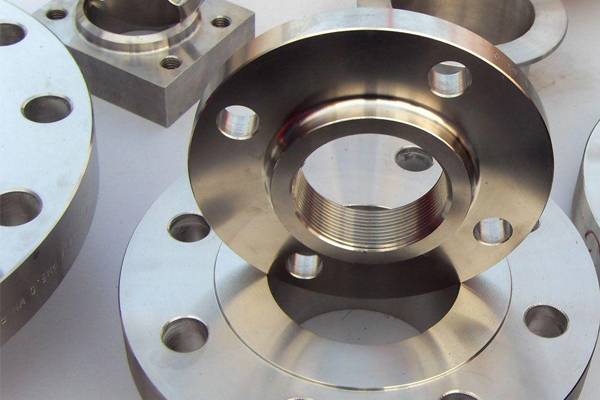

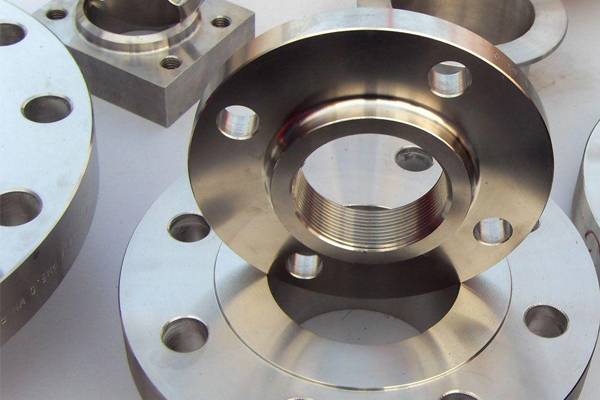

How to find the processing difficulties of stainless steel flange

First of all, before choosing the drill bit, take a look at the difficulties in stainless steel flange processing. Find out the difficulty can be very accurate, very fast to find the use of the dri...Read more -

What is the process of forging?

1. Isothermal forging is to keep the temperature of billet constant during the whole forming process. Isothermal forging is used to take advantage of the high plasticity of certain metals at consta...Read more -

The main disadvantages of water as a quenching cooling medium for forgings ?

1) in the austenite isothermal transformation diagram of the typical area, that is, about 500-600℃, water in the steam film stage, the cooling rate is not fast enough, often cause uneven cooling an...Read more -

What kind of bolt connection does stainless steel flange use?

Customers often ask: stainless steel flange connection whether to choose stainless steel bolts? Now I will write what I have learned to share with you: Material has nothing to do with the material...Read more -

How to use welding flange correctly

Flanges With the rapid development of domestic foreign minister pipeline construction, pipeline pressure test has become an essential important link, before and after the pressure test, must pass t...Read more -

Applications of hardenability and hardenability of forgings

Hardenability and hardenability are the performance indexes that characterize the quenching ability of forgings, and they are also the important basis for selecting and using materials.Hardenabilit...Read more -

The way to improve the plasticity of forging and reduce the deformation resistance

In order to facilitate the flow forming of metal billet, reduce the deformation resistance and save equipment energy, the following methods are generally adopted in forging process: 1) Grasp the ma...Read more -

Flange standard

Flange standard: National standard GB/T9115-2000, Ministry of Machinery STANDARD JB82-94, Ministry of Chemical Industry standard HG20595-97HG20617-97, Ministry of Electric Power standard GD0508 ~ 0...Read more -

What are the methods of forging cleaning

Forgings cleaning is the process of removing surface defects of forgings by mechanical or chemical means. In order to improve the surface quality of forgings, improve the cutting conditions of forg...Read more -

Defects and Countermeasures of large forgings: Uneven microstructure and properties

Large forgings, due to their large size, many processes, long cycle, non-uniformity in the process, and many unstable factors, often cause serious non-uniformity in the microstructure, so that they...Read more -

Defects and Countermeasures of large forgings: Forging cracks

In large forging, when the quality of raw materials is poor or forging process is not at the right time, forging cracks are often easy to occur. The following introduces several cases of forging cr...Read more