News

-

How many heating methods do you know about forgings before forging?

Preforging heating is an important link in the whole forging process, which has a direct influence on improving forging productivity, ensuring forging quality and reducing energy consumption. The p...Read more -

Cooling and heating methods for stainless steel forgings

According to the different cooling speed, there are three cooling methods of stainless steel forgings: cooling in the air, cooling speed is faster; The cooling speed is slow in the sand; Cooling in...Read more -

Knowledge of machining and forging round

Forging round belongs to a kind of forgings, in fact, a simple point is the round steel forging processing. Forging round has obvious difference with other steel industry, and forging round can be ...Read more -

Knowledge of grain size of forgings

Grain size refers to the grain size within a grain size crystal. The grain size can be expressed by the average area or average diameter of the grain. The grain size is expressed by the grain size ...Read more -

What are the methods of forging cleaning?

Forging cleaning is the process of removing surface defects of forgings by mechanical or chemical methods. In order to improve the surface quality of forgings, improve the cutting conditions of for...Read more -

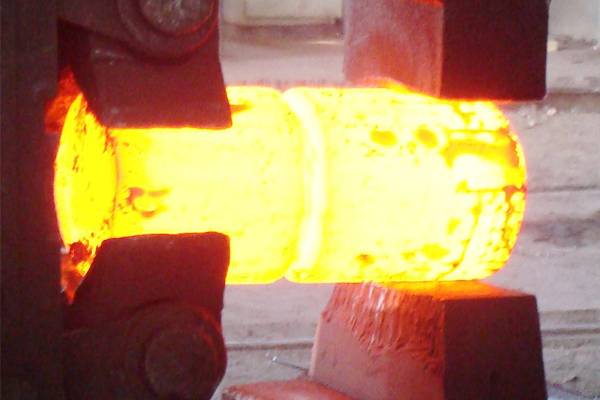

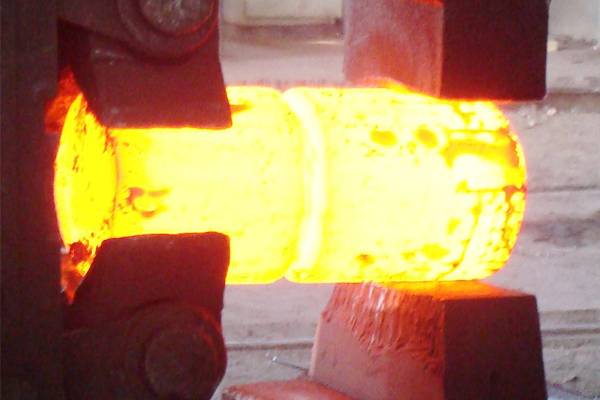

Defects in forgings when heated

1. Beryllium oxide: beryllium oxide not only loses a lot of steel, but also reduces the surface quality of the forgings and the service life of the forging die. If pressed into the metal, the forgi...Read more -

DHDZ: What should be paid attention to when determining the forging process size design?

Forging process size design and process selection are carried out at the same time, therefore, in the design of process size should pay attention to the following points: (1) Follow the law of cons...Read more -

What is forging oxidation? How to prevent oxidation?

When the forgings are heated, the residence time is too long at high temperature, the oxygen in the furnace and the oxygen in the water vapor combine with the iron atoms of the forgings and the phe...Read more -

What are the considerations in the design of custom flan?

Today's flange, is to become our life and many industries, can be used to seal products. Therefore, today's flange application or a very wide range of customized flanges has become a product that c...Read more -

What is the future development trend of cold forging process?

Cold forging is a kind of precision plastic forming technology, with machining incomparable advantages, such as good mechanical properties, high productivity and high material utilization, particul...Read more -

Why do die forgings fail?

The so-called forging die failure refers to the forging die can not be repaired to restore its use function of damage, that is, caused by the damage or scrap of the commonly said forging die. Becau...Read more -

What is the inspection procedure for forging products?

The inspection procedure of forged products is as follows: ① All forgings should be cleaned before acceptance of finished products. Free forgings may not be cleaned. ② Before the acceptance of fini...Read more