News

-

Free forgings production forgings several points for attention

The tools and equipment used for free forging are simple, universal and low cost. Compared with casting blank, free forging eliminates shrinkage cavity, shrinkage porosity, porosity and other defec...Read more -

What are the forging equipment?

With the development of heavy industry, forging equipment is also diverse. Forging equipment refers to the mechanical equipment used for forming and separating in forging process. Forging equipment...Read more -

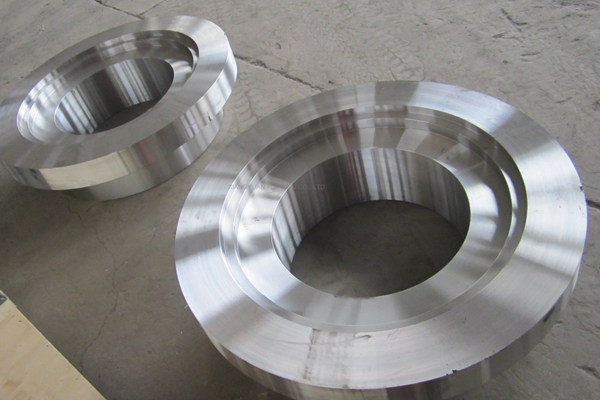

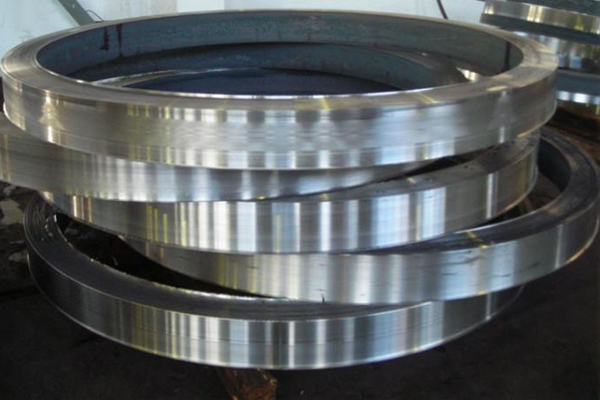

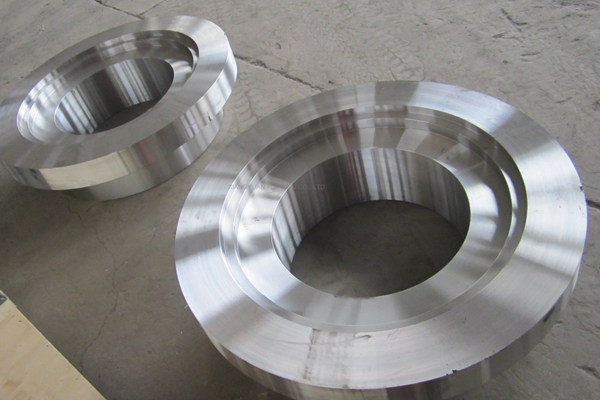

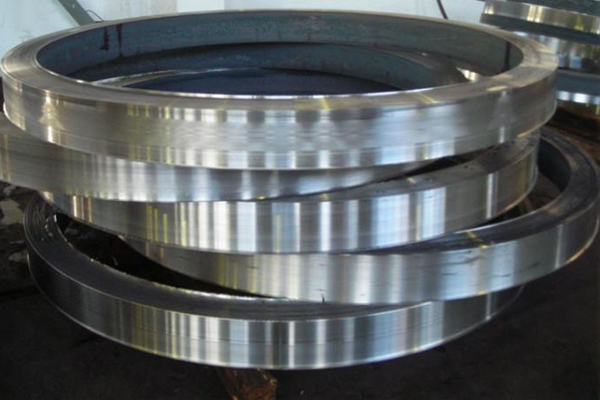

Various forging processes of large diameter flange

There are many types of large diameter flange forging process, and the flange price difference is not small. Large diameter flange forging process is as follows: 1. This process is mainly used for ...Read more -

Flange connection

Flange connection is to fix two pipes, pipe fittings or equipment respectively on a flange plate, and the flange pad is added between the two flanges, which is fastened together with bolts to compl...Read more -

What should be improved in the production process of forging parts

In today's use of forging parts, if the temperature control is bad or the careless will cause a series of defects in the process of production, this will reduce the quality of the forging parts, in...Read more -

Factors influencing flange use degree

In the case of common coarseness of flanges, different steel grades and different winding methods have different fatigue limit reduction degrees, such as the decrease degree of hot coil flanges is ...Read more -

Cooling and heating methods for stainless steel forgings

According to the different cooling speed, there are three cooling methods of stainless steel forgings: cooling in the air, cooling speed is faster; The cooling rate is slow in lime sand. In the fur...Read more -

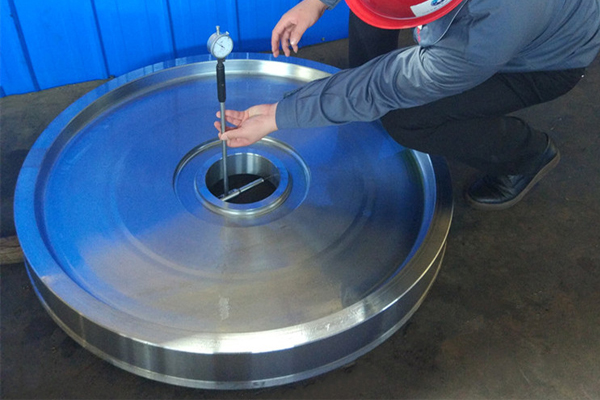

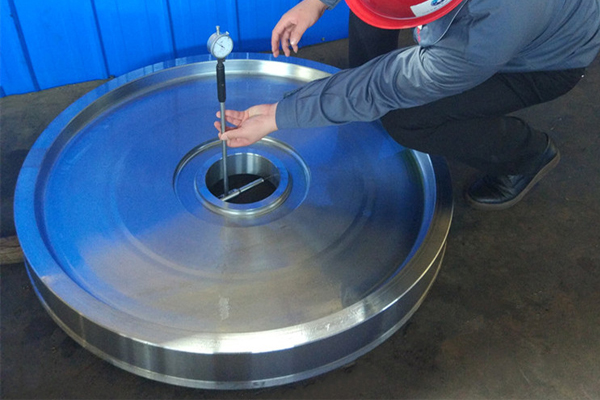

Inspection of appearance quality of forgings

Appearance quality inspection is generally a non-destructive inspection, usually with the naked eye or low magnifying glass inspection, if necessary, also use non-destructive inspection method. The...Read more -

What should we pay attention to in terms of safety during forging processing?

During the forging process, in terms of safety, we should pay attention to: 1. forging production is carried out in the state of metal burning (for example, 1250~750℃ range of low carbon steel forg...Read more -

Forging: How to forge good forgings?

Now the fittings in the industry mostly use forging way, DHDZ provides high-quality forgings, so now when forging, what raw materials are used? The forging materials are mainly carbon steel and all...Read more -

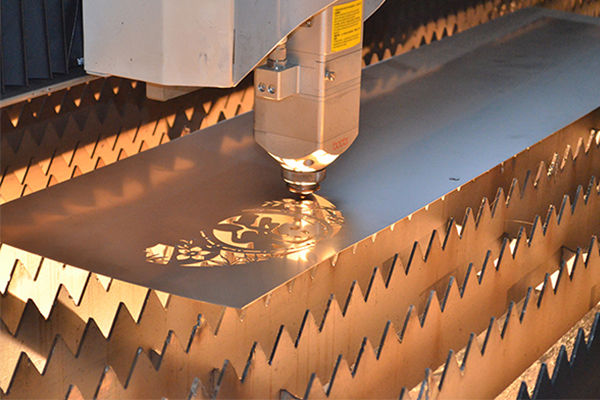

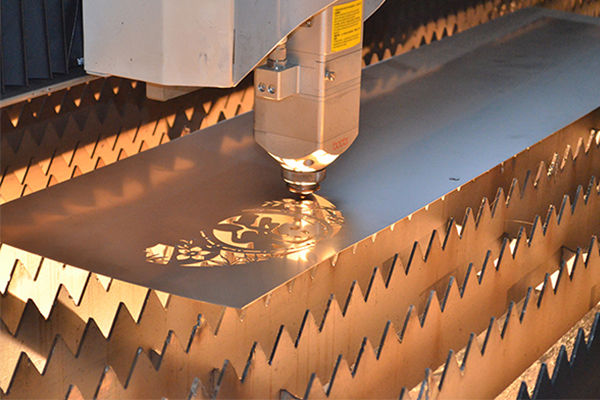

Focus media | DHDZ dingxiang comprehensive newspaper front page news headlines!

On September 30th (Thursday), the general section of Dingxiang News carried a headline on Shanxi Donghuang Wind Power Flange Manufacturing Co.,Ltd introducing LASER cutting machine for CNC machine ...Read more -

What should we pay attention to in terms of safety during forging processing?

During the forging process, in terms of safety, we should pay attention to: 1. forging production is carried out in the state of metal burning (for example, 1250~750℃ range of low carbon steel forg...Read more