1, butt welding flange annealing temperature is up to the specified temperature, butt welding flange treatment is generally taken solution heat treatment, that is, people usually so-called "annealing", the temperature range is 1040~1120℃. You can also observe through the annealing furnace observation hole, the flange fittings in the annealing area should be incandescent, but there is no softening sagging.

2, annealing atmosphere, butt welding flange is generally used as pure hydrogen annealing atmosphere, the purity of the atmosphere is more than 99.99%, if the other part of the atmosphere is inert gas, the purity can also be a little lower, but can not contain too much oxygen, water vapor.

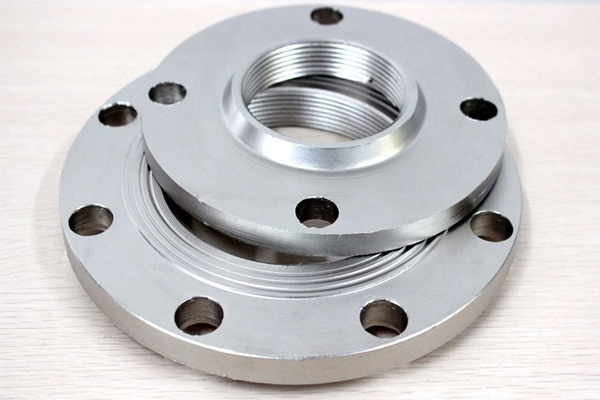

Butt welding flange

3, butt welding flange protection gas pressure, in order to prevent butt welding flange leakage, the furnace protection gas should maintain a certain positive pressure, if it is hydrogen protection gas, generally requires more than 20kBar.

4, welding flange processing water vapor in the casting furnace, on the one hand, check whether the furnace material is dry, the furnace material must be dried for the first time; The second is whether the flange pipe fittings into the furnace remain too much water stains, especially if there are holes in the flange pipe fittings, do not leak in, otherwise the furnace atmosphere will be completely destroyed.

5, butt welding flange furnace body sealing, butt welding flange bright annealing furnace should be closed, isolated from the outside air; With hydrogen as a protective gas, only one vent is open. The method of inspection can be used to wipe the cracks of each joint in the annealing furnace with soap and water to see whether to run; Among them, the place that is easy to run is the place where the annealing furnace enters the pipe and the place where the pipe comes out. The sealing ring in this place is especially easy to wear and tear, so it should be checked and changed frequently.

Post time: Apr-12-2022