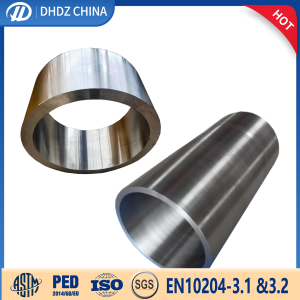

Peratra Gear Steel Alloy

Product Details:

Toerana niaviany: Shanxi

Anaran'ny marika: DHDZ

Fanamarinana: ASME, JIS, DIN, GB, BS, EN, AS, SABS, ASTM A370, API 6B, API 6C

Tatitra fitsapana: MTC, HT, UT, MPT, Tatitra momba ny refy, Fitsapana hita maso, EN10204-3.1, EN10204-3.2

Kaomandy kely indrindra: 1 piece

Fonosana fitaterana: Kitapo plywood

Vidiny: azo ifanarahana

Fahaizana famokarana: 100PCS / Volana

| singa ara-materialy | C | Mn | P | S | SI | Cr | NI | Mo | Cu | N |

| 4140 | 0.43 | 1.0 | <0,030 | <0,040 | <0.35 | 0.8-1.1 | <0,030 | 0.15-0.25 | <0,030 | / |

| F6Mn | ≤ 0.05 | 1.0 | ≤ 0.03 | ≤0.03 | ≤0.60 | 11-14 | 3.5-5.5 | 0.5-1 | / | / |

| 09G2S ( 09Г2С ) | ≤ 0.12 | 1.3-1.7 | ≤ 0.03 | ≤ 0,035 | 0.5-0.8 | ≤ 0.3 | ≤ 0.3 | / | ≤ 0.3 | ≤ 0,008 |

| 35NiCrMoV12-5 | 0.30-0.40 | 0.4-0.7 | ≤ 0,015 | ≤ 0,015 | ≤ 0.35 | 1.0-1.4 | 2.5-3.5 | 0.35-0.65 | / | / |

| 20MnMo | 0.17-0.23 | 1.1-1.4 | ≤0.025 | ≤0.015 | 0.17-0.37 | ≤0.030 | ≤0.030 | 0.20-0.35 | / | / |

| 20MnMoNo | 0.16-0.23 | 1.2-1.5 | ≤0.035 | ≤0.035 | 0.17-0.37 | / | / | 0.45-0.60 | / | 0.20-0.45 |

| Fananana mekanika | Dia.(mm) | TS/Rm (Mpa) | YS/Rp0.2 (Mpa) | EL/A5 (%) | RA/Z (%) | Notch | Hery misy fiantraikany | HBW |

| 4140 | Ф10 | >1080 | >930 | > 25 | > 45 | V | ≥25J(-60 ℃) | <217 |

| F6Mn | / | ≥790 | ≥620 | ≥15 | ≥45 | V | / | ≤295 |

| 09G2S ( 09Г2С ) | Ф25 | 900-1050 | ≥700 | ≥10 | ≥50 | V | / | / |

| 35NiCrMoV12-5 | Ф12.5 | ≥1100 | ≥850 | ≥8.0 | / | V | / | / |

| 20MnMo | Ф10 | ≥605 | ≥475 | ≥25 | / | V | ≥180 | / |

| 20MnMoNo | Ф10 | ≥635 | ≥490 | ≥15 | / | U | ≥47 | 187-229 |

Fomba famokarana:

Fanaraha-maso ny kalitaon'ny fikorianan'ny fizotry ny fizotry ny fikorianan'ny rivotra: ingot vy akora manta ao anaty trano fanatobiana entana (mitsapa ny votoaty simika) → fanapahana → fanafanana (fitsapana ny mari-pana ao amin'ny lafaoro) → fitsaboana hafanana aorian'ny fametahana (fitsapana ny mari-pana ao amin'ny lafaoro) Esory ny lafaoro (fanitsiana banga) → Machining → Inspection (UT). ,MT, Visal diamention, hamafin'ny)→ QT→ Fanaraha-maso (UT, toetra mekanika, hamafin'ny, haben'ny voa)→ Vita machining → Inspection (dimension) → Fonosana sy marika (marika vy, marika) → Fitehirizana entana

Tombontsoa:

Toetra mekanika tsara,

Fandeferana dimensional avo lenta,

Mifehy tsara ny fomba famokarana,

Fitaovana fanamboarana mandroso sy fitaovana fanaraha-maso,

Tena toetra ara-teknika,

Mamokatra refy samihafa mifototra amin'ny filan'ny mpanjifa,

Tandremo ny fiarovana ny fonosana,

Serivisy feno kalitao.