Theproblema obsignationisFlanges planae conglutinatae semper res calida fuit, sive ad sumptum productionis sive ad commodum oeconomicum societatum pertinens, itaque principium obsignationis flanges planae conglutinatae emendatum et emendatum est. Attamen, principale vitium designandi flanges planae conglutinatae est quod effusionem impedire non potest. Hoc vitium designandi est: conexio dynamica est, et onera periodica, ut expansio thermalis et onera fluctuantia, possunt causare...flangefacies inter se moveri impellunt, functionem flangis afficientes, ita integritatem flangis corrumpentes et tandem ad effluxum ducentes.

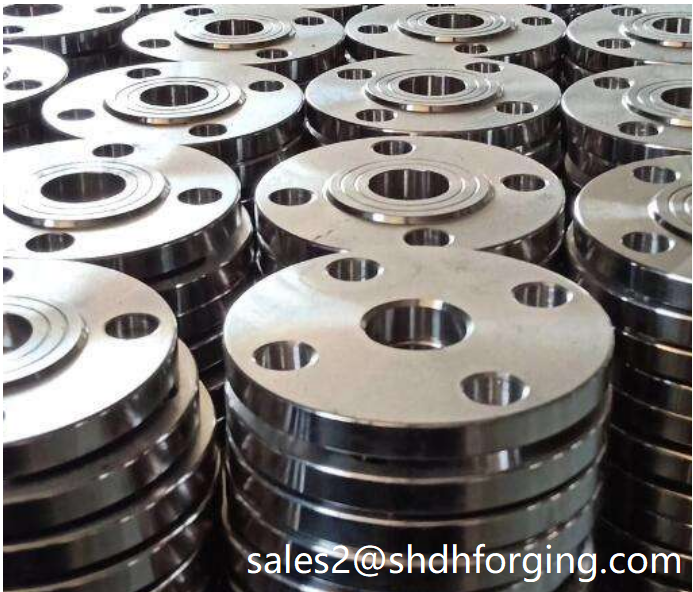

Nullum productum sine vitiis esse potest, sed conare vitia producti ad minimum cohibere, ergo societas in productione flangarum planarum sudatoriarum, quantum fieri potest, maximum munus agit ad efficaciam producti emendandam. Proprietates flangarum planarum sudatoriarum: flanga plana sudatoria non solum spatium conservat, pondus minuit, et iuncturas sine effluxu, bonam efficaciam obsignationis efficit. Diametro obsignationis reducto, magnitudo flangae compactae et sectio obsignationis minuuntur.

Deinde, obturamentum flangis anulo obturante substituendum est, ut superficies obturans superficiei obturanti congruat. Hoc modo, parva tantum vis necessaria est ad superficiem obturantem stringendam. Cum pressio requisita minuitur, magnitudo et numerus clavorum minores fiunt, itaque parvum volumen et leve pondus novi producti designamus, pondus flangis traditionalis ー 70%-80% reducere possumus. Ergo, flanges planae ad soldandum sunt producti flangis altae qualitatis, qualitatem et spatium minuerunt, et magnum munus in applicatione industriali gesserunt.

Principium obturationis flangis planae sudatae: duae facies obturantes clavorum obturationem flangis comprimunt ad obturationem formandam, sed hoc etiam damnum obturationis causare potest. Ad obturationem servandam, magnam vim clavorum servare debes, et ad hoc faciendum, clavum maiorem facere debes. Clavus maior maiori nuci respondet, quod significat diametrum clavorum maiorem requiri ad condiciones creandas ad nucem stringendam. Sed quo maior diameter clavorum, eo curvatura flangis fiet; sola via est crassitudinem parietis partis flangis augere.

Quaestio obsignationis flangarum planarum conglutinatarum semper res calida fuit, sive ad sumptus productionis sive ad commodum oeconomicum societatum pertinens. Itaque principium obsignationis flangarum planarum conglutinatarum emendatum et emendatum est. Attamen, principale vitium designandi flangarum planarum conglutinatarum est quod effusionem impedire non potest. Hoc vitium designandi est: conexio dynamica est, et onera periodica, ut expansio thermalis et onera fluctuantia, superficies flangarum inter se movere possunt, functionem flangarum afficientes, ita integritatem flangarum corrumpens et tandem ad effusionem ducens.

Nullum productum sine vitiis esse potest, sed conare vitia producti ad minimum cohibere, ergo societas in productione flangarum planarum sudatoriarum, quantum fieri potest, maximum munus agit ad efficaciam producti emendandam. Proprietates flangarum planarum sudatoriarum: flanga plana sudatoria non solum spatium conservat, pondus minuit, et iuncturas sine effluxu, bonam efficaciam obsignationis efficit. Diametro obsignationis reducto, magnitudo flangae compactae et sectio obsignationis minuuntur.

Deinde, obturamentum flangis anulo obturante substituendum est, ut superficies obturans superficiei obturanti congruat. Hoc modo, parva tantum vis necessaria est ad superficiem obturantem stringendam. Cum pressio requisita minuitur, magnitudo et numerus clavorum minores fiunt, itaque parvum volumen et leve pondus novi producti designamus, pondus flangis traditionalis ー 70%-80% reducere possumus. Ergo, flanges planae ad soldandum sunt producti flangis altae qualitatis, qualitatem et spatium minuerunt, et magnum munus in applicatione industriali gesserunt.

Principium obturationis flangis planae sudatae: duae facies obturantes clavorum obturationem flangis comprimunt ad obturationem formandam, sed hoc etiam damnum obturationis causare potest. Ad obturationem servandam, magnam vim clavorum servare debes, et ad hoc faciendum, clavum maiorem facere debes. Clavus maior maiori nuci respondet, quod significat diametrum clavorum maiorem requiri ad condiciones creandas ad nucem stringendam. Sed quo maior diameter clavorum, eo curvatura flangis fiet; sola via est crassitudinem parietis partis flangis augere.

A: 168 fabricae reticulatae

Tempus publicationis: XX Aprilis MMXX