Inspectio qualitatis speciei plerumque est inspectio non destructiva, plerumque oculo nudo vel vitro amplificante humili inspectio; si opus est, etiam methodo inspectionis non destructiva utitur.

Methodi inspectionis qualitatis internaefabricae gravesSummari possunt sic: inspectio ordinationis macroscopicae, inspectio ordinationis microscopicae, inspectio proprietatum mechanicarum, analysis compositionis chemicae, et probationes non destructivae.

Examen microstructurae macroscopicae est genus probationis ad observandas et analysandas proprietates microstructurae parvae potentiae.fabricatioper vitrum amplificans visuale vel parvae potentiae. Methodi vulgo adhibitae ad inspectionem structurae macroscopicaefabricaesunt methodus corrosionis parvae potentiae (inter quas corrosio thermalis, corrosio frigida et methodus corrosionis electrolytica), probatio fracturae et methodus impressionis sulphuris.

Regula inspectionis microstructurae est microscopio lucido uti ad microstructuram inspiciendam.fabricaevariarum materiarum. Res inspiciendae plerumque magnitudinem grani intrinsecam, vel magnitudinem grani ad temperaturam definitam, id est magnitudinem grani actualem, inclusionem non-metallicam, microstructuram ut stratum decarburizationis, inhomogeneitatem carburi eutectici, supercalefactionem, superustionem et aliam microstructuram requisitam, etc. comprehendunt.

Proprietates mechanicae et inspectio effectus processus ultima curatio caloris fuisse dicitur.fabricaeet partes probationis in exemplum definitum processae sunt post usum machinae probationis tensile, machinae probationis impactus, machinae probationis tolerantiae, machinae probationis lassitudinis, probatoris duritiei, aliorumque instrumentorum ad proprietates mechanicas et valores effectuum processus determinandos.

Examen compositionis chemicae plerumque adhibetur analysis chemica vel spectralis partium fabricatarum. Cum scientia et technologia evolutis, et analysis chemica et spectralis instrumenta analytica progressum fecerunt. In analysi spectrali, non solum methodus spectralis et spectroscopica ad analysin partium perficiendam adhibetur; spectrometri photoelectrici non solum celeritatem analysis, sed etiam accuratiam magnopere aucti sunt. Spectrometri photoelectrici plasmatici autem accuratiam analysis magnopere auxerunt, cuius accuratio ad gradum 10-6 pervenire potest. Haec methodus valde efficax est ad vestigia impuritatum noxiarum, ut Pb, As, Sn, Sb, Bi, in fabricatis supermixtis analyticis analysanda.

Supra dictum, methodus probationis, ordinatio macroscopica, et probatio sive effectus sive methodus compositionis sive microstructurae, omnia ad methodum probationis destructivae pertinent, nam nonnullae partes graves fabricatae methodorum destructivarum requisitis inspectionis qualitatis plene accommodari non possunt, ex una parte, quia non sunt oeconomicae, ex altera parte praecipue ad vitandam unilateralitatem probationis destructivae. Progressus technologiae NDT media magis provecta et perfecta praebet ad...fabricatioinspectio qualitatis

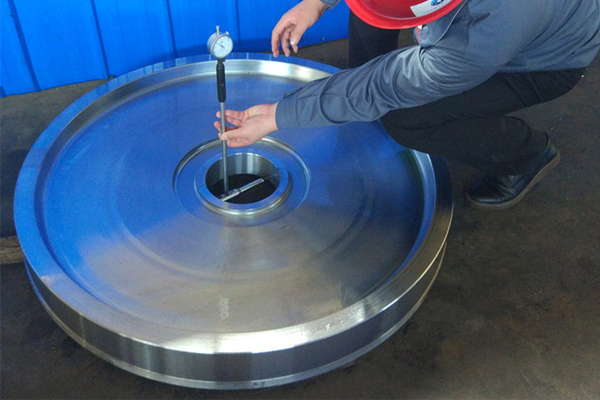

Methodi probationum non destructivarum ad inspiciendum qualitatem fabricationis plerumque sunt: methodus inspectionis pulveris magnetici, methodus inspectionis penetrationis, methodus inspectionis currentis turbillonarii, methodus inspectionis ultrasonica.

Methodus inspectionis particularum magneticarum late adhibetur ad vitia superficialia vel prope superficiem metalli vel mixturae ferromagneticae inspicienda.fabricae, ut fissurae, rugæ, maculae albae, inclusiones non metallicae, delaminatio, plicatura, fasciae carburi vel ferriticae, etc. Haec methodus tantum apta est ad inspectionem ferromagneticarumfabricae, sed non pro cudendo ex chalybe austenitico facto.

Methodus inspectionis penetrantis non solum materias magneticas fabricatas inspicere potest, sed etiam vitia superficialia materiae non ferromagneticae.fabricae, ut fissurae, laxitas, plicaturae, etc. Generaliter, tantum ad vitia superficialia materiarum non ferromagneticarum fabricatarum examinanda adhibetur, nec vitia occulta sub superficie invenire potest. Probatio currentium turbillonariarum ad vitia superficialia vel prope superficiem materiarum conductivarum examinanda adhibetur.

Methodus inspectionis ultrasonicae adhibetur ad vitia interna fragmentorum fabricatorum inspicienda, ut cavitas contractionis, macula alba, fissura in medio, inclusio scoriae, et cetera. Quamquam haec methodus commoda, celeris et oeconomica est, difficile est accurate naturam vitiorum determinare.

Tempus publicationis: XVII Kalendas Decembres, MMXXI