1. isothermal uzuzubụ na usoro dum nke ịmepụta okpomọkụ billet iji nọgide na-enwe uru mgbe niile.Isothermal ịgha mkpụrụbụ iji nnukwu plasticity nke ụfọdụ ọla mee ihe n'ụzọ zuru ezu n'otu okpomọkụ, ma ọ bụ iji nweta microstructure na ihe onwunwe kpọmkwem. Isothermal forging chọrọ mgbe niile okpomọkụ nke anwụ na billet ọnụ, nke na-achọ nnukwu ego na-eji naanịpụrụ iche forgingusoro, dị ka superplastic akpụ.

2.ịgha ụghanwere ike ịgbanwe nhazi ígwè, melite arụmọrụ ígwè. Mgbena-ekpo ọkụ foring, ihe nkedo mbụ ahụ rụrụ arụ, pores, micro-cracks na ihe ndị ọzọ na-ejikọta ma ọ bụ welded; A na-agbaji kristal dendritic mbụ na ọka na-adị mma. N'otu oge ahụ na-agbanwe mbụ carbide nkewa na-erughị eru nkesa, na-eme ka Ọdịdị edo, otú iji nweta esịtidem ok, edo, ezi, ezi keukwu arụmọrụ, a pụrụ ịdabere na ojiji nke forging. Mgbe na-ekpo ọkụ forging deformation, metal bụ fibrous anụ ahụ; Mgbe emechara nrụrụ oyi, kristal ọla na-egosi usoro.

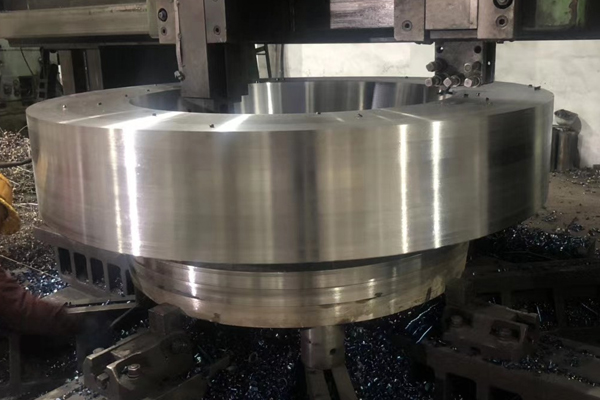

3. ịgha ụghabụ ime ka metal plastic na-eruba na-eme ka a chọrọ udi nke workpiece. Olu nke ígwè na-adịgide adịgide mgbe plastik na-asọpụta site na ike mpụga, na ígwè ahụ na-aga n'ihu mgbe niile na akụkụ ahụ na-eguzogide obere ihe. Na mmepụta, na workpiece udi na-emekarị na-achịkwa dị ka ndị a iwu na-aghọta iwe iwe ịbịaru, oghere ịgbasa, ekwe, ịbịaru na ndị ọzọ deformation.

4. ịgha ụghanke workpiece size bụ ezi, na-eme ka uka mmepụta nzukọ.Nwuo ịgha ụgha, extrusion, stamping na ngwa ndị ọzọ nke ebu akpụ size ezi, kwụsiri ike. Enwere ike iji igwe na-arụ ọrụ dị elu na-arụ ọrụ na-arụ ọrụ na-emepụta ahịrị na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe ma ọ bụ mmepụta oke ọkachamara.

5. ịgha ụghausoro mmepụta gụnyere ịgha mkpụrụ billet,ịgha ụghakpo oku billet na pretreatment tupu akpụ; Okpomọkụ ọgwụgwọ, ihicha, calibration na nnyocha nke workpiece mgbe akpụ. Igwe eji akpụ akpụ a na-ejikarị nwere hama, igwe igwe mmiri na igwe igwe. Hama a na-akpụ akpụ nwere nnukwu mmetụta ọsọ ọsọ, na-enyere aka na-asọba plastik metal, mana ọ ga-emepụta mkpọtụ; Hydraulic press na static forging, na-eme ka akpụpụta site na ígwè ma melite nzukọ, ọrụ kwụsiri ike, mana obere nrụpụta; Mechanical pịa ọrịa strok edobere, dị mfe ịghọta igwe na akpaaka.

N'ọdịnihu,ịgha ụghana ịpị teknụzụ ga-azụlite iji melite n'ime àgwà nke forging na ịpị akụkụ, ịzụlite nkenke forging na stamping technology, ịzụlite forging ngwá na forging mmepụta akara na elu arụpụtaghị na akpaaka, ịzụlite mgbanwe mgbanwe.ịgha ụghana ịpị usoro, mepụta ọhụrụịgha ụghaihe naịgha ụghausoro nhazi. Iji melite esịtidem àgwà nke forging akụkụ bụ tumadi ka mma ha n'ibu Njirimara (ike, plasticity, siri ike, ike ọgwụgwụ ike) na ntụkwasị obi. Nke a na-achọ ka mma ngwa nke metal plastic deformation tiori; Ngwa nke ihe kacha mma n'ime; ziri ezitupu ịgha ụghakpo oku na ịgha ọgwụgwọ okpomọkụ; Nnwale siri ike na nke sara mbara na-adịghị emebi emebi nke akụkụ adịgboroja.

Oge nzipu: Ọktoba 18-2021