Nleba anya ọdịdị ọdịdị bụ nleba anya na-adịghị emebi emebi, na-ejikarị anya gba ọtọ ma ọ bụ nleba anya dị ala, ọ bụrụ na ọ dị mkpa, na-ejikwa usoro nyocha na-adịghị emebi emebi.

The nnyocha ụzọ nke esịtidem àgwà nkearọ forgingsnwere ike ichikota dị ka: macroscopic nzukọ nnyocha, microscopic nzukọ nnyocha, n'ibu Properties nnyocha, chemical mejupụtara analysis na-abụghị mbibi ule.

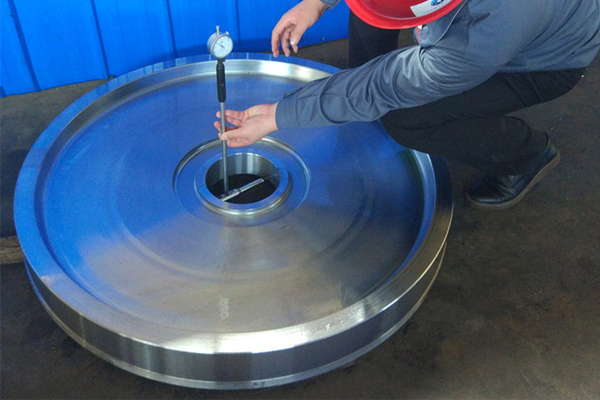

Nnwale macroscopic microstructure bụ ụdị nnwale iji lelee na nyochaa njirimara microstructure dị ala nkeịgha ụghasite na anya ma ọ bụ obere ike na-ebuli elu. A na-ejikarị ụzọ maka nyocha ihe owuwu macroscopic nkeforgingsbụ usoro nrụrụ dị ala (gụnyere corrosion thermal, corrosion oyi na usoro corrosion electrolytic), ule mgbaji na usoro mbipụta sọlfọ.

Iwu nleba anya nke microstructure bụ iji mikroskopu ọkụ lelee microstructure nkeforgingsnke ihe dị iche iche. Ihe nyocha n'ozuzu na-agụnye oke ọka intrinsic, ma ọ bụ nha ọka na okpomọkụ a kapịrị ọnụ, ya bụ nha ọka n'ezie, nsonye na-abụghị ọla, microstructure dị ka oyi akwa decarburization, eutectic carbide inhomogeneity, oke ọkụ, oke ọkụ na ihe ndị ọzọ achọrọ microstructure, wdg.

Mechanical Njirimara na usoro nyocha ọrụ bụ na ọ bụla ọgwụgwọ okpomọkụ ikpeazụ nkeforgingsna mpempe ule esichara n'ime a kpọmkwem sample mgbe ojiji nke tensile ule igwe, mmetụta ule igwe, ntachi obi ule igwe, ike ọgwụgwụ ule igwe, hardness tester na ndị ọzọ ngwá iji chọpụta n'ibu Njirimara na hazie arụmọrụ ụkpụrụ.

Nnwale ihe mejupụtara kemịkalụ bụ n'ozuzu iji nyocha kemịkalụ ma ọ bụ spectral analysis of forging components analysis and test, na mmepe nke sayensị na teknụzụ, ma nyocha kemịkalụ na nyocha spectral nke nyocha ya pụtara na-enwe ọganihu. N'ihi na spectral analysis, ugbu a ọ bụghị nanị iji spectral usoro na spectroscopic usoro iji mepụta akụrụngwa analysis, mpụta nke photoelectric spectrometer ọ bụghị naanị ngwa ngwa nyocha, ma na-mma nke ukwuu izi ezi, na mpụta nke plasma photoelectric spectrometer emewo ka nke ọma analysis ziri ezi, ya analysis ziri ezi nwere ike iru 10-6 larịị, usoro a dị irè nke ukwuu maka nyocha nke P, dị ka S na-emerụ ahụ. superalloy forgings.

E kwuru n'elu, usoro nke ule, macroscopic nzukọ, na mejupụtara na microstructure ule ma ọ bụ arụmọrụ ma ọ bụ usoro, niile bụ nke na-ebibi ule usoro, n'ihi na ụfọdụ arọ forgings nke na-ebibi ụzọ enweghị ike kpamkpam imeghari ka chọrọ nke àgwà nnyocha, n'otu aka ahụ, nke a bụ n'ihi na ọ bụghị aku na uba, na n'aka nke ọzọ bụ tumadi iji zere otu-akụkụ ule mbibi. Mmepe nke teknụzụ NDT na-enye ụzọ dị elu na nke zuru oke makaịgha ụghaàgwà nnyocha.

Uzo nnwale na-adịghị emebi emebi maka nyocha ịdị mma bụ n'ozuzu: usoro nyocha ntụ ntụ magnetik, usoro nyocha ntinye, usoro nyocha nke ugbu a, usoro nyocha ultrasonic.

A na-eji usoro nyocha ihe ndọta ọtụtụ ebe iji nyochaa elu ma ọ bụ nso ntụpọ elu nke metal ferromagnetic ma ọ bụ alloy.forgings, dị ka cracks, wrinkles, na-acha ọcha tụrụ, na-abụghị ọla inclusions, delamination, mpịachi, carbide ma ọ bụ ferritic bands, wdg Usoro a bụ naanị kwesịrị ekwesị maka nnyocha nke ferromagnetic.forgings, ma ọ bụghị maka forging mere nke austenitic ígwè.

Usoro nyocha penetrant nwere ike ọ bụghị naanị lelee ihe ndọta ndọta, kamakwa lelee ntụpọ elu nke ihe na-abụghị ferromagnetic.forgings, dị ka cracks, looseness, mpịachi, wdg N'ozuzu, ọ na-eji naanị na-elele n'elu ntụpọ nke na-abụghị ferromagnetic ihe forgings, na-apụghị ịhụ zoro ezo ntụpọ n'okpuru elu. A na-eji nnwale Eddy ugbu a iji lelee ntụpọ elu ma ọ bụ nso ntụpọ nke ihe ndị na-eduzi.

A na-eji usoro nyocha nke Ultrasonic iji lelee ntụpọ esịtidem nke forgings dị ka oghere shrinkage, ntụpọ ọcha, mgbape isi, nsonye slag, wdg.

Oge nzipu: Nov-17-2021