Flange ịgbado ọkụ dị larịịdị ka ọkacha mmasị gị si dịịgha ụghaanwụ ije, ọ nwere ike kewaa n'ime swing rolling, swing rotaryịgha ụgha, mpịakọta forging, wedge mpịakọta, mgbanaka Rolling, cross Rolling na na. Enwere ike iji ịhịa aka nke ọma mee ihe n'ịgbagharị, ịgbagharị rotary forging na mgbanaka mgbanaka. Enwere ike iji ịhịa aka n'ahụ na ịfegharị obe mee ihe dị ka ọgwụgwọ maka ihe ndị dị gịrịgịrị iji melite ojiji ihe. Dị ka akpụ akpụ n'efu, a na-emepụta rotary forging na-enwekwa uru nke ịmepụta ọ bụrụgodị na ike ịgha ahụ erughị nha akpụ. Enwere ike ịmechaa forgings mgbagwoju anya n'otu usoro ma ọ bụ karịa. N'ihi na ọ dịghị akụkụ burr, ebe a na-emepụta ihe na-emepụta ihe na-ebelata ma na-ebelata ibu achọrọ.

Nke aịgha ụghausoro na-eme ka ihe ahụ gbasaa site na nso flange mgbe a na-arụ ya. N'ihi na anya dị n'etiti anwụ anwụ na elu free dị iche iche, ọ na-esiri ike ikwenye nkenke. Ya mere, site n'ịchịkwa ije ntụziaka nke forging anwụ na rotary forging usoro site na kọmputa, ngwaahịa ndị nwere mgbagwoju udi na elu nkenke nwere ike ịmepụta. Ee, enwere m ike ime ya. Enwetara ya na ike ịgha mkpụrụ dị ala. Uzuoku turbine agụba na ụdị ndị ọzọ na nnukwu nhaforgingsmmepụta ihe.

Flange ịgbado ọkụ dị larịị ịgha ụghaenwere ike kewaa n'efuịgha ụgha, iwe iwe , extrusion , anwụ forging , mechiri emechi anwụ forging na mechiri emechi iwe iwe forging . N'ozuzu, a na-akpọ ịgha n'ime recrystallization okpomọkụ nso a na-akpọ forging na-ekpo ọkụ, na ụlọ okpomọkụ na-enweghị kpo oku forging ka a na-akpọ oyi forging. Mgbe oleflanges welded dị larịịbụemegorona obere okpomọkụ, akụkụ nkeforgingso siri ike ịgbanwe. Mgbe emechara n'okpuru 700 ℃, ọ fọrọ nke nta ka ọ bụrụ na ọ nweghị ọnụ ọgụgụ oxide etolite na enweghị decarburization elu.

Flange ịgbado ọkụ dị larịịakara akara: abụọ akara n'elu nke bolts pịa na flange gasket na-etolite a akara, nke nwekwara ike iduga akara mmebi. Iji nọgide na-enwe akara, ọ dị mkpa iji nọgide na-enwe nnukwu ihe mgbochi, ya mere na-amụba ihe mkpuchi ahụ. Nnukwu bolts kwesịrị dakọtara na nnukwu mkpụrụ. Nke a pụtara na ị ga-achọ bolts dayameta buru ibu iji mepụta ọnọdụ maka imechi akị ahụ.

Mara makaflange ịgbado ọkụ ewepụghị

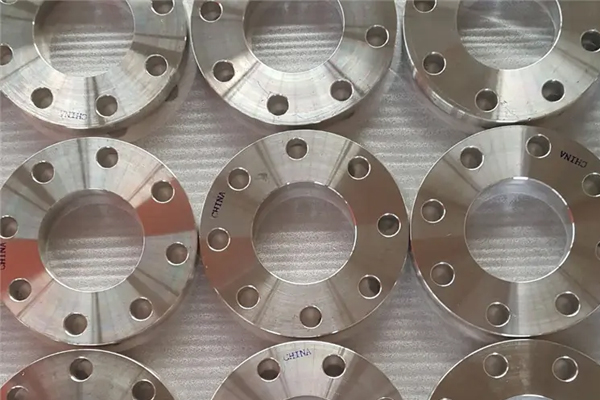

1. Efere ígwè eji arụ ọrụflanges welded dị larịịa na-emepụta ma jiri ya mee ihe site na nyocha ultrasonic na-enweghị delamination, iji chọpụta àgwà dị mma na nsogbu arụmọrụ, na-arụpụta ma na-anwale dị ka ihe dị mma chọrọ, efere ígwè anaghị enwe nsogbu dị mma.

2. A na-egbutu ígwè n'ime mpekere n'akụkụ ntụgharị ntụgharị, wee gbadaa na butt welded n'ime mgbanaka, na-akpụ elu okirikiri na nchara. The cylinder. N'ịmepụta flanges dị larịị, efere ígwè ekwesịghị ka a na-eji ya eme ihe ozugbo na flange olu, kama nke a na-emepụta ya ma jiri usoro a kapịrị ọnụ rụọ ya.

Oge nzipu: Jun-13-2022