Hot Sale for Forged Pipe - Forged Bars – DHDZ

Hot Sale for Forged Pipe - Forged Bars – DHDZ Detail:

Open Die Forgings Manufacturer In China

Forged Bars

Common used material: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV12

FORGED BAR SHAPES

Round bars, Square bars, Flat bars and Hex bars. All Metals has the forging capabilities to produce bars from the following alloy types:

● Alloy steel

● Carbon steel

● Stainless steel

FORGED BAR CAPABILITIES

ALLOY

MAX WIDTH

MAX WEIGHT

Carbon, Alloy

1500mm

26000 kgs

Stainless Steel

800mm

20000 kgs

FORGED BAR CAPABILITIES

The maximum length for forged round bars and hex bars is 5000 mm, with a maximum weight of 20000 kgs.

The maximum length and width for flat bars and square bars is 1500mm, with a maximum weight of 26000 kgs.

A forged bar or a rolled bar is produced by taking an ingot and forging it down to size by, generally, two opposing flat dies. Forged metals tend to be stronger, harder and more durable than cast forms or machined parts. You can get a wrought grain structure throughout all sections of the forgings, increasing parts ablitity to withstand warping and wearing.

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., as an ISO registered certified forging manufacturer, guarantee that the forgings and/or bars are homogenous in quality and free of anomalies which are detrimental to the mechanical properties or machining properies of the material.

Case:

Steel Grade EN 1.4923 X22CrMoV12-1

Structure Martensitic

|

Chemical composition % of steel X22CrMoV12-1 (1.4923): EN 10302-2008 |

||||||||

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

V |

|

0.18 - 0.24 |

max 0.5 |

0.4 - 0.9 |

0.3 - 0.8 |

max 0.025 |

max 0.015 |

11 - 12.5 |

0.8 - 1.2 |

0.25 - 0.35 |

Applications

Powerplant, Machine engineering, Power generation.

Components for pipe-lines, steam boilers and turbines.

Delivery form

Round bar, Rolled Forgings Rings, Bored roundbars, X22CrMoV12-1 Forged bar

Size: φ58x 536L mm.

Forging (Hot Work ) Practice

Materials are loaded in furnace and heated. When the temperture reaches 1100℃, metal will be forged. It refers to any mechanical process that shapes metal ulilizing one or more dies, e.g. open/closed die forging, extrusion, rolling, etc. During this process, the temperture of metal falls. When it decreases to 850℃, metal will be heated again. Then repeat hot work at that elevated temperature(1100℃). The minimum ratio for hot work ratio from ingot to billet is 3 to 1.

Heat Treatment Procedure

Load the preheat treat machining material into heat treatment furance. Heat to temperature of 900 ℃. Hold at temp for 6 hours 5 minutes. Oil quench and temper at 640℃.Then Air-cool.

Mechanical properties of X22CrMoV12-1 forged bar (1.4923).

| Rm - Tensile strength (MPa) (+QT) |

890 |

| Rp0.2 0.2% proof strength (MPa) (+QT) |

769 |

| KV - Impact energy (J) (+QT) |

-60° 139 |

| A - Min. elongation at fracture (%) (+QT) |

21 |

| Brinell hardness (HBW): (+A) | 298 |

Any material grades, other than above mentioned, can be forged as per the customer's requirement.

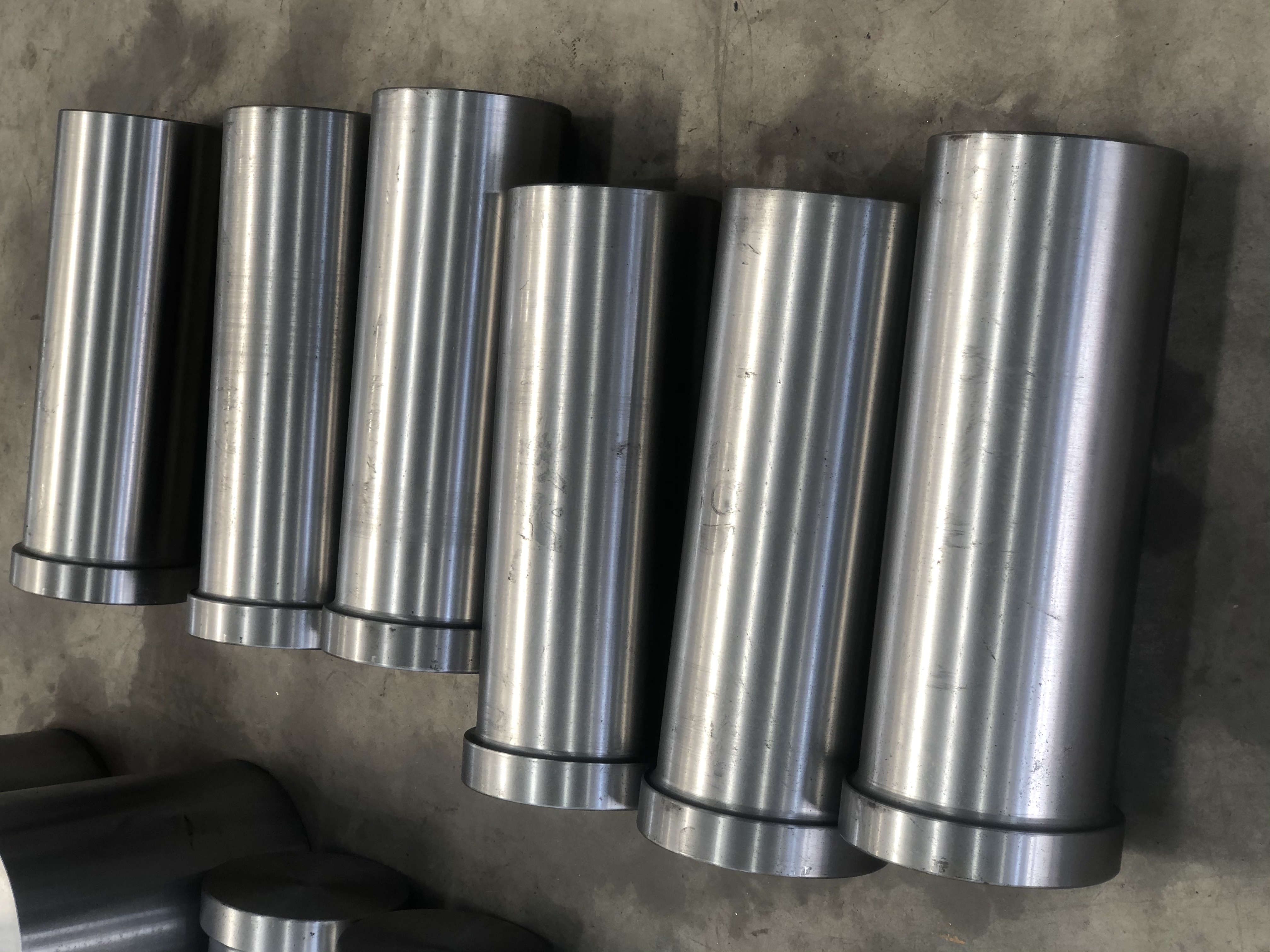

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future jointly with your esteemed company for Hot Sale for Forged Pipe - Forged Bars – DHDZ , The product will supply to all over the world, such as: Borussia Dortmund, Paraguay, Egypt, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!