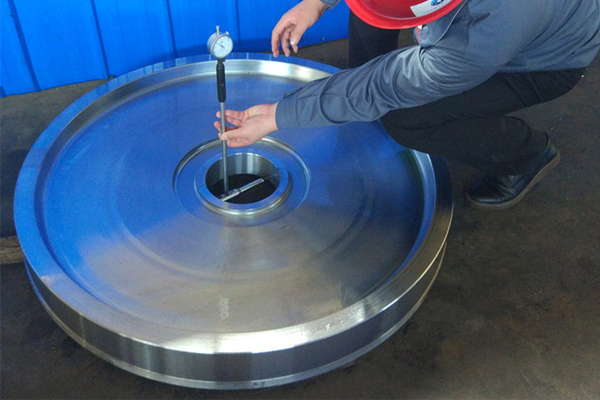

Kev soj ntsuam zoo yog feem ntau yog ib qho kev tshuaj xyuas tsis muaj kev puas tsuaj, feem ntau yog nrog qhov muag liab qab lossis tsis tshua pom iav tsom iav, yog tias tsim nyog, kuj siv txoj kev tshuaj ntsuam xyuas uas tsis muaj kev puas tsuaj.

Kev soj ntsuam txoj hauv kev zoo ntawmhnyav forgingstuaj yeem sau tau raws li: kev tshuaj xyuas lub koom haum macroscopic, kev tshuaj xyuas lub koom haum microscopic, kev tshuaj xyuas cov khoom siv tshuaj, tshuaj lom neeg muaj pes tsawg leeg thiab kev kuaj tsis muaj kev puas tsuaj.

Macroscopic microstructure test yog ib hom kev ntsuam xyuas los soj ntsuam thiab txheeb xyuas cov yam ntxwv ntawm lub zog qis ntawm microstructureforginglos ntawm qhov muag pom lossis lub zog qis zog iav. Feem ntau siv txoj hauv kev rau kev tshuaj xyuas cov qauv macroscopicforgingsyog txoj kev siv hluav taws xob tsawg (xws li thermal corrosion, txias corrosion thiab electrolytic corrosion txoj kev), fracture test thiab sulfur printing method.

Kev tshuaj xyuas microstructure txoj cai yog siv lub teeb tsom iav los xyuas qhov microstructure ntawmforgingsntawm ntau yam ntaub ntawv. Cov khoom tshuaj ntsuam xyuas feem ntau suav nrog cov nplej loj, lossis cov nplej loj ntawm qhov ntsuas kub, piv txwv li cov nplej loj, cov khoom tsis yog xim hlau, microstructure xws li decarburization txheej, eutectic carbide inhomogeneity, overheat, overburn thiab lwm yam yuav tsum tau microstructure, thiab lwm yam.

Mechanical zog thiab cov txheej txheem kev soj ntsuam kev ua tau zoo yog kom tau txais kev kho cua sov kawg ntawm qhovforgingsthiab cov khoom kuaj ua tiav rau hauv cov qauv ntsuas tom qab siv lub tshuab ntsuas tensile, kev ntsuas lub cav, kev ntsuas lub zog, lub zog ntsuas tshuab, hardness tester thiab lwm yam cuab yeej los txiav txim siab cov khoom siv thiab cov txheej txheem kev ua tau zoo.

Kev ntsuam xyuas tshuaj muaj pes tsawg leeg feem ntau yog siv tshuaj ntsuam xyuas lossis spectral tsom xam ntawm forging Cheebtsam tsom xam thiab kev sim, nrog rau kev txhim kho ntawm kev tshawb fawb thiab thev naus laus zis, ob qho tib si tshuaj ntsuam xyuas thiab spectral tsom xam ntawm nws txoj kev tsom xam txhais tau tias muaj kev vam meej. Rau kev tsom xam spectral, tam sim no tsis yog tsuas yog siv txoj kev spectral thiab spectroscopic txoj kev los ua cov tshuaj tiv thaiv, qhov tshwm sim ntawm photoelectric spectrometer tsis tsuas yog kev soj ntsuam ceev, tab sis kuj zoo heev txhim kho qhov raug, thiab qhov tshwm sim ntawm plasma photoelectric spectrometer tau zoo heev txhim kho qhov kev soj ntsuam qhov tseeb, nws qhov kev tsom xam qhov tseeb tuaj yeem ncav cuag 10-6 qhov kev ntsuam xyuas zoo li no, Pb, As, Sn, Sb, Bi hauv superalloy forgings.

Hais saum toj no, cov txheej txheem ntawm kev xeem, macroscopic lub koom haum, thiab muaj pes tsawg leeg thiab microstructure xeem los yog kev ua tau zoo los yog txoj kev, tag nrho cov nyob rau hauv txoj kev ntsuam xyuas kev puas tsuaj, rau ib co hnyav forgings ntawm kev puas tsuaj tsis tuaj yeem hloov mus rau qhov yuav tsum tau muaj kev soj ntsuam zoo, ntawm ib sab, qhov no yog vim nws tsis yog kev lag luam, ntawm qhov tod tes, feem ntau yog kom tsis txhob muaj kev puas tsuaj ntawm ib sab. Kev txhim kho ntawm NDT thev naus laus zis muab ntau dua thiab txhais tau tias zoo meej rauforgingkev soj ntsuam zoo.

Nondestructive xeem txoj kev forging zoo soj ntsuam yog feem ntau: sib nqus hmoov tshuaj xyuas txoj kev, nkag mus soj ntsuam txoj kev, eddy tam sim no soj ntsuam txoj kev, ultrasonic soj ntsuam txoj kev.

Magnetic particle soj ntsuam txoj kev yog dav siv los tshuaj xyuas qhov chaw los yog ze ntawm qhov chaw ntawm ferromagnetic hlau los yog alloy.forgings, xws li cov kab nrib pleb, wrinkles, dawb me ntsis, tsis yog xim hlau inclusions, delamination, folding, carbide los yog ferritic bands, thiab lwm yam. Txoj kev no tsuas yog tsim nyog rau kev soj ntsuam ntawm ferromagnetic.forgings, tab sis tsis yog rau forging ua los ntawm austenitic hlau.

Penetrant tshuaj xyuas txoj kev tuaj yeem tsis tsuas yog xyuas cov khoom sib nqus forgings, tab sis kuj xyuas qhov tsis xws ntawm cov khoom tsis-ferromagnetic.forgings, xws li cov kab nrib pleb, looseness, folding, thiab lwm yam. Feem ntau, nws tsuas yog siv los xyuas qhov tsis xws luag ntawm cov khoom tsis yog ferromagnetic forgings, thiab tsis tuaj yeem pom qhov tsis xws luag hauv qab ntawm qhov chaw. Eddy kev ntsuam xyuas tam sim no yog siv los txheeb xyuas qhov chaw lossis ze ze ntawm qhov tsis xws luag ntawm cov khoom siv hluav taws xob.

Ultrasonic tshuaj xyuas txoj kev yog siv los xyuas qhov tsis xws luag ntawm forgings xws li shrinkage kab noj hniav, qhov chaw dawb, core crack, slag inclusion, thiab lwm yam.

Post lub sij hawm: Nov-17-2021