Cov cuab yeej thiab cov cuab yeej siv rau kev forging dawb yog qhov yooj yim, universal thiab tus nqi qis. Piv nrog rau casting dawb paug,dawb forgingtshem tawm qhov shrinkage kab noj hniav, shrinkage porosity, porosity thiab lwm yam tsis xws luag, yog li ntawd lub blanks muaj ntau dua mechanical zog.Forgingsyog cov qauv yooj yim thiab hloov tau yooj yim hauv kev ua haujlwm. Yog li ntawd, nws yog ib qho tseem ceeb tshwj xeeb hauv kev tsim cov tshuab hnyav thiab cov khoom tseem ceeb.

Daim ntawv thov teb

Dawb forgingsyog tswj los ntawm phau ntawv ua haujlwm ntawm cov duab thiab qhov loj ntawmforgings, yog li ntawdforging precisiontsis tshua muaj, kev ua haujlwm pub dawb yog qhov loj, kev siv zog ua haujlwm loj, kev tsim khoom tsis siab, yog li nws yog siv rau hauv ib qho, me me batch ntau lawm.

1) Qhov loj ntawm billet thiab nruab nrab loj yuav tsum ua raws li cov ntsiab lus ntawm kev khiav hauj lwm ntawm txhua tus txheej txheem, xws li qhov siab-inch ratio (H / D) ntawm cov khoom ua ntej upsetting yog 2-2.5, thiab cov ntaub ntawv empirical ntawm seem transformation thaum kos tawm.

2) Nws yog ib qho tsim nyog los kwv yees qhov kev hloov pauv ntawm qhov khoob loj hauv qhovforging txheej txheem,Piv txwv li, qhov siab dawb paug yog txo thaum xuas nrig ntaus, feem ntau 1.1 npaug ntawm qhov siab forging; Thaum lub core ncej reaming qhov siab yog nce.

3) seem indentation, yuav tsum xyuas kom meej tias txhua feem ntawm lub forging muaj txaus ntim, xws li nyob rau hauv lub kauj ruam ncej, crankshaft los yog iav tus thawj billet, ua ib tug zoo txoj hauj lwm ntawm lub ntim faib ntawm txhua feem.

4) Thaumforgingnrog ntau qhov hluav taws kub, kev saib xyuas yuav tsum tau them rau qhov muaj peev xwm ua kom sov txhua qhov hluav taws kub hauv nruab nrab. Yog tiasforgingsyog rub ntev heev thaum pib, qhov cub loj loj tsis txaus los muab tso rau hauv qhov ntev forgings thaum lub sijhawm cua sov thib ob. Txhawm rau kom ntseeg tau tias qhov loj thiab qhov zoo ntawm forgings, kev saib xyuas tshwj xeeb yuav tsum tau them rau qhov deformation ntawm qhov hluav taws kub tom qab Z thiab tswj qhov kub thiab txias ntawm thawj thiab zaum kawg forging tom qab Z.

5) Nws yog ib qho tsim nyog los xyuas kom meej tias muaj cov nyiaj txiav txaus txaus tom qab ua tiav tom qab Z, thiab yuav tsum tau them nyiaj rau:

(1) Vim hais tias nyob rau hauv tus txheej txheem ntawm nias lub xub pwg nyom, tshem tawm, xuas nrig ntaus thiab lwm yam, muaj ib tug tshwm sim ntawm kev kos duab thiab shrinking nyob rau hauv qhov dawb paug, uas yuav tsum tau tawm ib tug hnav khaub ncaws pub nyob rau hauv nruab nrab txheej txheem;

(2) Forging ntevncej forgings(xws li crankshafts, thiab lwm yam) thiabforgingsnrog concave blocks, vim hais tias lawv qhov ntev me me tsis tuaj yeem ntxhov siab dua, nws yuav tsum tau kwv yees tias qhov loj ntawm qhov ntev ntawm qhov kev taw qhia yuav raug ncua me ntsis hauv kev hnav khaub ncaws thiab ua rau tsis muaj kev zam.

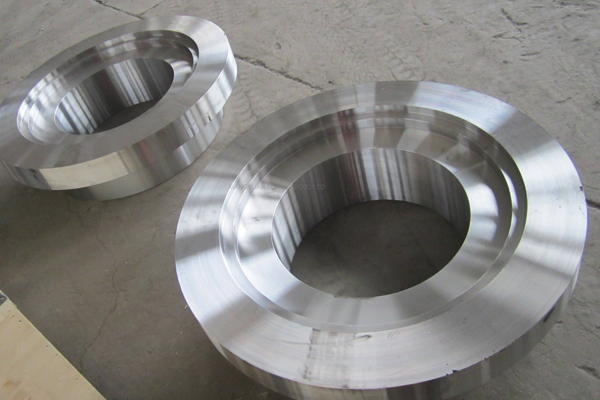

Forging.

6) Thaum xaiv cov cuab yeej, cov menyuam yaus yuav tsum siv cov cuab yeej dav dav. Thaum cov batch ntau lawm loj, cov cuab yeej tshwj xeeb lossis cov log tsheb tuaj yeem ua tau los txhim kho qhov zoo thiab cov khoom tsim tawm ntawm forgings.

7) Raws li qhov loj thiab qhov zoo ntawm qhov khoob, xaiv cov khoom siv uas twb muaj lawm hauv kev cob qhia.

Post lub sij hawm: Dec-15-2021