1. hana ʻana i ka isothermalaia i ke kaʻina holoʻokoʻa o ka hana ʻana i ka wela billet e mālama i ka waiwai mau.ʻO ka hana ʻana i ka isothermalʻo ia ka hoʻohana piha ʻana i ka plasticity kiʻekiʻe o kekahi mau metala i ka mahana like, a i ʻole e loaʻa i kahi microstructure a me nā waiwai. Pono ka hoʻoheheʻe Isothermal i ka mahana mau o ka make a me ka billet, pono ke kumukūʻai kiʻekiʻe a hoʻohana wale ʻiakuʻi kuikawanā kaʻina hana, e like me ka hana ʻana i ka superplastic.

2.ke kalaiwa anahiki ke hoʻololi i ke ʻano metala, hoʻomaikaʻi i ka hana metala. Ma hopehoʻopaʻa wela, ua hoʻopaʻa ʻia a hoʻopaʻa ʻia ka mea hoʻolei mua, pores, micro-cracks a pēlā aku; Ua haki ʻia nā kristal dendritic mua a maikaʻi nā hua. I ka manawa like e hoʻololi i ka hoʻokaʻawale ʻana o ka carbide a me ka hoʻokaʻawale ʻole ʻana, e hana i ke ʻano like ʻole, i mea e loaʻa ai ka paʻa o loko, ʻaʻahu, maikaʻi, maikaʻi maikaʻi ka hoʻohana ʻana i ka forging. Ma hope o ka wela forging deformation, metala mea fibrous kikokiko; Ma hope o ka hoʻololi ʻana o ka hoʻoheheʻe ʻana i ke anuanu, hōʻike nā kristal metala i ke ʻano.

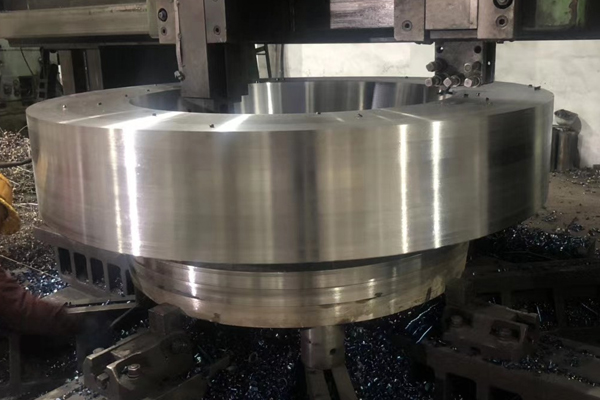

3. ke kalaiwa anaʻo ia ka hoʻoheheʻe ʻana i ka plastik metala a hana i ke ʻano i makemake ʻia o ka mea hana. Hoʻomau ka nui o ka metala ma hope o ke kahe ʻana o ka plastic i hana ʻia e ka ikaika o waho, a kahe mau ka metala i ka ʻāpana me ka liʻiliʻi loa. I ka hana ʻana, hoʻomalu pinepine ʻia ke ʻano o ka mea hana e like me kēia mau lula no ka ʻike ʻana i ke kaha kiʻi huhū, ka hoʻonui ʻana o ka lua, ke kulou, ke kaha kiʻi a me nā deformation ʻē aʻe.

4. ke kalaiwa anaʻO ka nui o ka mea hana he pololei, kūpono i ka hui hana nui.Make forging, extrusion, stamping a me nā noi ʻē aʻe o ka mold forming size correct, stable. Hiki ke hoʻohana ʻia nā mīkini forging kiʻekiʻe a me ka laina hana forging maʻalahi e hoʻonohonoho i ka hana nui a i ʻole ka hana nui.

5. ke kalaiwa anaʻO ke kaʻina hana e pili ana i ka hana ʻana i ka billet blanking,ke kalaiwa anaka hoʻomehana billet a me ka hoʻomaʻamaʻa mua ʻana ma mua o ka hana ʻana; Hoʻomaʻamaʻa wela, hoʻomaʻemaʻe, calibration a nānā i ka mea hana ma hope o ka hana ʻana. ʻO nā mīkini forging maʻamau i hoʻohana ʻia he hāmare forging, hydraulic press a me mechanical press. He hopena nui ka wikiwiki o ka hāmare forging, kūpono i ke kahe metala plastic, akā e hoʻopuka i ka haʻalulu; Hydraulic press me static forging, ua conducive i forging ma o ka metala a hoʻomaikaʻi i ka hui, paʻa hana, akā, haʻahaʻa huahana; Mechanical press stroke paʻa, maʻalahi e hoʻomaopopo i ka mechanization a me ka automation.

I ka wā e hiki mai ana,ke kalaiwa anaa e hoʻomohala ka ʻenehana kaomi e hoʻomaikaʻi i ka maikaʻi o loko o ka forging a me ke kaomi ʻana i nā ʻāpana, hoʻomohala i ka ʻenehana forging a me ka stamping, hoʻomohala i nā mea hana forging a me ka forging production line me ka kiʻekiʻe o ka huahana a me ka automation, hoʻomohala i ka maʻalahi.ke kalaiwa anaa me ka ʻōnaehana kaomi, hoʻomohala houke kalaiwa anamea a meke kalaiwa anakaʻina hana. No ka hoʻomaikaʻi ʻana i ka maikaʻi o loko o nā ʻāpana forging ʻo ia ka hoʻomaikaʻi ʻana i kā lākou mau waiwai mechanical (ikaika, plasticity, paʻakikī, ikaika luhi) a me ka hilinaʻi. Pono kēia i ka hoʻohana maikaʻi ʻana i ke kumumanaʻo deformation metala plastic; ʻO ka hoʻohana ʻana i nā mea waiwai maikaʻi loa; Pololeihana muaka hoʻomaʻamaʻa ʻana a me ka hana ʻana i ka wela; ʻOi aku ka paʻakikī a me ka nui o ka hoʻāʻo ʻole luku ʻana i nā ʻāpana forging.

Ka manawa hoʻouna: ʻOkakopa-18-2021