ʻO ka nānā ʻana i ka maikaʻi o ka hiʻohiʻona ʻo ia ka nānā ʻole luku ʻole, maʻamau me ka maka ʻōlohelohe a i ʻole ka nānā aniani hoʻonui haʻahaʻa, inā pono, e hoʻohana pū i ke ʻano nānā ʻole luku.

Nā ʻano nānā o ka maikaʻi o loko onā kalaiwa kaumahahiki ke hōʻuluʻulu ʻia e like me: ka nānā ʻana i ka hui macroscopic, ka nānā ʻana i ka hui microscopic, ka nānā ʻana i nā waiwai mechanical, ka nānā ʻana i ka haku mele a me ka hoʻāʻo ʻole luku.

ʻO ka hoʻāʻo macroscopic microstructure kahi ʻano hoʻāʻo e nānā a nānā i nā ʻano microstructure haʻahaʻa haʻahaʻake kalaiwa anama ke aniani hoʻonui ʻike a i ʻole ka mana haʻahaʻa. ʻO nā ʻano hana maʻamau no ka nānā ʻana i ka hale macroscopicnā kalaiwaʻO ke ʻano hana ʻino haʻahaʻa haʻahaʻa (me ka hoʻoheheʻe wela, ka corrosion anuanu a me ke ʻano ʻino electrolytic), ka hoʻāʻo ʻana a me ke ʻano paʻi sulfur.

ʻO ke kānāwai nānā microstructure e hoʻohana i ka microscope māmā e nānā i ka microstructure onā kalaiwao na mea like ole. Loaʻa nā mea nānā i ka nui o ka palaoa intrinsic, a i ʻole ka nui o ka palaoa i ka mahana i ʻōlelo ʻia, ʻo ia hoʻi ka nui o ka palaoa maoli, ka hoʻokomo ʻole ʻana i ka metallic, microstructure e like me ka decarburization layer, eutectic carbide inhomogeneity, overheat, overburn a me nā microstructure e pono ai, etc.

Mechanical waiwai a me ke kaʻina hana nānā 'ana ua i ka hope wela lapaʻau o kanā kalaiwaa me nā ʻāpana hoʻāʻo i hana ʻia i loko o kahi laʻana i ʻōlelo ʻia ma hope o ka hoʻohana ʻana i ka mīkini hoʻāʻo tensile, ka mīkini hoʻāʻo hopena, ka mīkini hoʻāʻo hoʻomanawanui, ka mīkini hoʻāʻo luhi, ka mea hōʻike paʻakikī a me nā mea hana ʻē aʻe e hoʻoholo ai i nā waiwai mechanical a me ke kaʻina hana waiwai.

ʻO ka hoʻāʻo ʻana i ka haku mele ʻana ka hoʻohana ʻana i ka loiloi kemika a i ʻole ka spectral analysis o ka forging component analysis a me ka hoʻāʻo ʻana, me ka hoʻomohala ʻana o ka ʻepekema a me ka ʻenehana, ua holomua ka loiloi kemika a me ka spectral analysis o kāna ʻano loiloi. No ka nānā ʻana i nā spectral, ʻaʻole ia e hoʻohana wale i ke ʻano spectral a me ke ʻano spectroscopic e hoʻokō i ka nānā ʻana i nā ʻāpana, ʻo ka puka ʻana mai o ka spectrometer photoelectric ʻaʻole wale ka nānā wikiwiki ʻana, akā hoʻomaikaʻi nui hoʻi i ka pololei, a ʻo ka puka ʻana mai o ka plasma photoelectric spectrometer ua hoʻomaikaʻi maikaʻi loa i ka pololei o ka nānā ʻana, hiki i kāna hōʻiliʻili pololei ke hiki i ka pae 10-6, ʻo kēia ʻano hana he maikaʻi loa no ka nānā ʻana, ʻo ia hoʻi. Sb, Bi i nā mea hoʻoheheʻe superalloy.

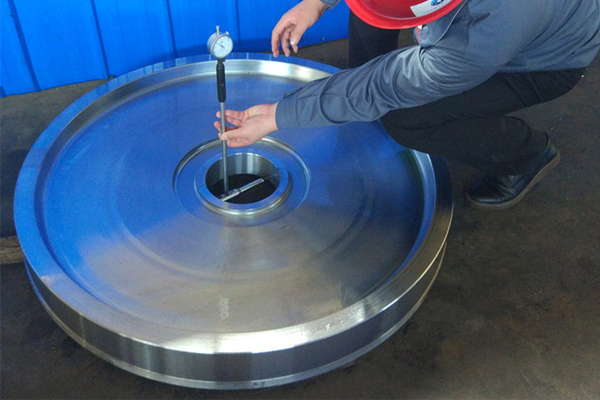

Ua ʻōlelo ʻia ma luna, ʻo ke ʻano o ka hoʻāʻo, ka hui macroscopic, a me ka hoʻohui ʻana a me ka microstructure hōʻike a i ʻole ka hana a i ʻole ke ʻano, aia nā mea āpau i ke ʻano hoʻāʻo luku, no ka mea, ʻaʻole hiki ke hoʻololi pono i kekahi mau hana hoʻomāinoino i ke koi o ka nānā ʻana i ka maikaʻi. ʻO ka hoʻomohala ʻana o ka ʻenehana NDT e hāʻawi i nā ala ʻoi aku ka holomua a me ka maikaʻi noke kalaiwa ananānā maikaʻi.

ʻO nā ʻano hoʻāʻo nondestructive no ka hoʻopaʻa ʻana i ka nānā ʻana i ka maikaʻi ma ke ʻano maʻamau: ke ʻano o ka nānā ʻana i ka pauka magnetic, ke ʻano o ka nānā ʻana i ke komo ʻana, ke ʻano o ka nānā ʻana i kēia manawa, ke ʻano nānā nānā ultrasonic.

Hoʻohana nui ʻia ke ʻano o ka nānā ʻana i nā ʻāpana magnetik e nānā i ka ʻili a i ʻole kokoke i nā hemahema o ka metala ferromagnetic a i ʻole ka alloy.nā kalaiwa, e like me nā māwae, wrinkles, keʻokeʻo keʻokeʻo, non-metallic inclusions, delamination, folding, carbide or ferritic bands, etc. He kūpono wale kēia ala no ka nānā ʻana i ka ferromagnetic.nā kalaiwa, akā, ʻaʻole no ka hana ʻana i ke kila austenitic.

ʻAʻole hiki ke nānā i ke ʻano o ka nānā ʻana Penetrant wale nō i ka hoʻopaʻa ʻana i nā mea magnetic, akā e nānā pū kekahi i nā hemahema o nā mea non-ferromagnetic.nā kalaiwa, e like me nā māwae, looseness, folding, etc. ʻO ka mea maʻamau, hoʻohana wale ʻia ia e nānā i nā hemahema o ka ʻili o nā mea hoʻoheheʻe ʻole ferromagnetic, a ʻaʻole hiki ke ʻike i nā hemahema huna ma lalo o ka ʻili. Hoʻohana ʻia ka hoʻāʻo ʻana o Eddy i kēia manawa e nānā i ka ʻili a kokoke i nā hemahema o ka ʻili o nā mea conductive.

Hoʻohana ʻia ke ʻano loiloi kani ultrasonic e nānā i nā hemahema o loko o ka forgings e like me ka shrinkage cavity, keʻokeʻo keʻokeʻo, core crack, slag inclusion, etc. ʻOiai ua maʻalahi kēia ʻano, wikiwiki a me ka waiwai, paʻakikī ke hoʻoholo pololei i ke ʻano o nā hemahema.

Ka manawa hoʻouna: Nov-17-2021