Flange wiliwili palahalahae like me kāu punaheleke kalaiwa anaka neʻe ʻana o ka make, hiki ke hoʻokaʻawale ʻia i loko o ka swing rolling, swing rotaryke kalaiwa ana, kaʻa ʻana i ka ʻōwili, ka ʻōwili wedge, ka ʻōwili apo, ka ʻōwili keʻa a pēlā aku. Hiki ke hoʻohana ʻia ka hoʻopololei pololei ʻana i ka swing rolling, swing rotary forging and ring rolling. Hiki ke hoʻohana ʻia ka ʻōwili ʻana a me ka ʻōwili keʻa ma ke ʻano he hoʻomaʻamaʻa mua ʻana no nā mea lohi e hoʻomaikaʻi ai i ka hoʻohana ʻana i nā mea. E like me ka forging manuahi, ʻo ka rotary forging ka mea i hana ʻia a loaʻa ka pōmaikaʻi o ka hana ʻana inā ʻoi aku ka ikaika o ka forging ma mua o ka nui forging. Hiki ke hoʻopau ʻia nā forging paʻakikī i hoʻokahi a ʻoi aku paha kaʻina hana. No ka mea, ʻaʻohe ʻaoʻao burr, ua hoʻemi ʻia ka ʻāpana forging bearing a hoʻemi ʻia ka ukana i koi ʻia.

ʻO kēiake kalaiwa anaʻO ke ala e hoʻonui ai i ka mea mai kahi kokoke i ka flange ke hana ʻia. No ka mea ʻokoʻa ka mamao ma waena o ka ʻili make a me ka ʻili manuahi, paʻakikī ke hōʻoia i ka pololei. No laila, ma ke kaohi ʻana i ka neʻe ʻana o ka forging die a me ka rotary forging process e ka kamepiula, hiki ke hana ʻia nā huahana me ke ʻano paʻakikī a me ka pololei kiʻekiʻe. ʻAe, hiki iaʻu ke hana. Loaʻa me ka mana forging haʻahaʻa. ʻO nā ʻūhā turbine mahu a me nā ʻano ʻē aʻe a me ka nui nuinā kalaiwahana hana.

Flange wiliwili palahalaha ke kalaiwa anahiki ke maheleia i kaawaleke kalaiwa ana, upsetting , extrusion , make forging , pani paʻa make forging a pani upsetting forging . Ma keʻano laulā, ua kapa ʻia ʻo forging i loko o ka recrystallization temperature range he hot forging, ma ka lumi wela me ka hoʻomehana ʻole ʻana ua kapa ʻia ʻo ke anuanu. I ka manawapalahalaha welded flangeshehoopunipunima ka wela haʻahaʻa, nā ana o kanā kalaiwahiki ole ke hoololi. Ke hana ʻia ma lalo o 700 ℃, ʻaneʻane ʻaʻohe unahi oxide i hoʻokumu ʻia a ʻaʻohe hana decarburization.

Flange wiliwili palahalahake kumu hoʻopaʻa paʻa: ʻo nā ʻili hoʻopaʻa ʻelua o nā bolts e kaomi ma luna o ka flange gasket e hana i kahi sila, a hiki ke alakaʻi i ka hōʻino sila. No ka mālamaʻana i ka sila, pono e mālama i ka ikaika nui o ka bolt, no laila e hoʻonui i ka pahu. Pono nā bolts nui i nā hua nui. ʻO ia ke ʻano e pono ai ʻoe i nā bolts anawaena nui aʻe e hana i nā kūlana no ka hoʻopaʻa ʻana i ka nati.

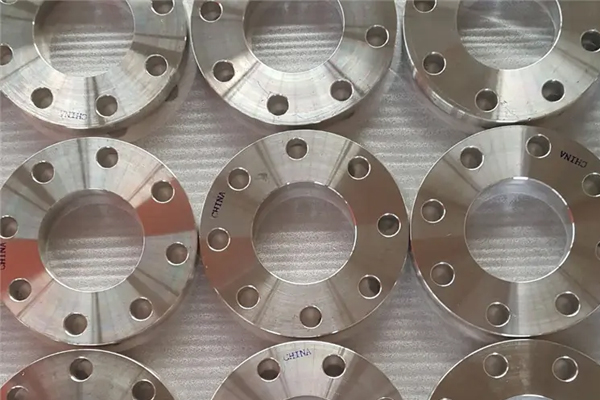

Nānā nowiliwili palahalaha

1. ʻO ka pā kila i hoʻohanaʻia no ka hanaʻanapalahalaha welded flangeshana ʻia a hoʻohana ʻia ma o ka nānā ʻana i ka ultrasonic me ka ʻole o ka delamination, i mea e ʻike ai i ka maikaʻi maikaʻi a me nā pilikia hana, a hana ʻia a hoʻāʻo ʻia e like me nā koi kikoʻī kikoʻī, ʻaʻohe pilikia o ka pā kila.

2. Ua ʻoki ʻia ke kila i mau ʻāpana ma ka ʻaoʻao o ka ʻōwili ʻana, a laila e kulou a hoʻopaʻa ʻia ke kī i loko o nā apo, e hana ana i ka ʻili pōʻai ma ke kila. ʻO ke kinikini. I ka hana ʻana i nā flanges flat-welded, ʻaʻole pono e hoʻopili pololei ʻia ka pā kila i ka ʻāʻī o ka ʻāʻī, akā hana ʻia a hana ʻia me ka hoʻohana ʻana i kahi ʻenehana kikoʻī.

Ka manawa hoʻouna: Iune-13-2022