Labaran Masana'antu

-

Dalilin zamewa ko rarrafe na piston silinda mai ruwa da kuma hanyar magani

Na'ura mai aiki da karfin ruwa piston zamewa ko rarrafe zai sa na'ura mai aiki da karfin ruwa Silinda aiki rashin zaman lafiya. Kun san dalilin hakan? Kun san abin da za ku yi da shi? Labari na gaba shine a gare ku ku yi magana akai. (1) na'ura mai aiki da karfin ruwa Silinda ciki astringency. Haɗin kai na cikin gida mara kyau ...Kara karantawa -

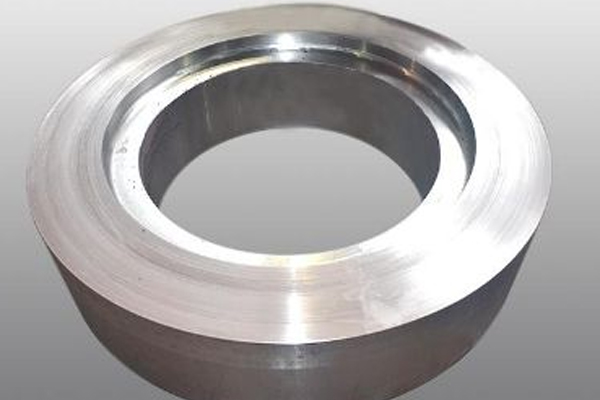

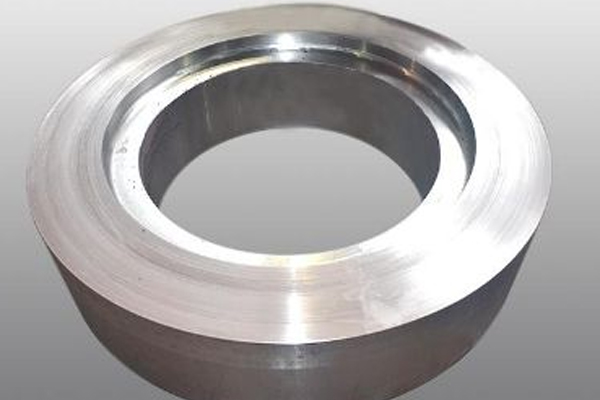

Fasalolin Flange da amfani da hankali

Flanges sassa ne masu siffar faifai da aka fi amfani da su wajen bututu. Ana amfani da flanges cikin nau'i-nau'i kuma tare da flanges masu dacewa akan bawuloli. A cikin injiniyan bututun, ana amfani da flange musamman don haɗa bututun. A cikin buƙatar haɗa bututun, kowane nau'in shigarwa na flange, ƙananan pip ...Kara karantawa -

Yadda za a inganta ingantaccen samarwa na ƙirƙira maganin zafi

【DHDZ】 Kamar yadda muka sani, maganin zafi yana da muhimmiyar hanyar haɗin gwiwa a cikin tsarin ƙirƙira, mai alaƙa da taurin ƙirƙira da sauran matsalolin, don haka ta yaya za a inganta haɓakar samar da ingantattun magungunan zafi? Inganta ingancin samar da maganin zafi, ta hanyar haɓaka cajin tanderu ...Kara karantawa -

Menene ya kamata a lura da shi a cikin jarrabawar ƙirƙira ta mutu kafin maganin zafi?

The dubawa kafin bayani zafi magani ne pre-duba hanya don duba ƙãre samfurin ta surface ingancin da girma bisa ga fasaha yanayi, mutu ƙirƙira zane da kuma aiwatar da katin bayan ƙirƙira kafa tsari da aka gama. Takamaiman dubawa yakamata ya biya atte ...Kara karantawa -

Hanyoyin haɗi daban-daban na gwiwar gwiwar flange

Flanges, ko flanges, sifofi ne masu kama da faifai masu ma'ana da ake amfani da su don haɗa bututu ko ƙayyadaddun sassa na inji. Yawancin lokaci ana gyara su da kusoshi da zaren. Ciki har da flange da bakin karfe flange gwiwar hannu, ba ku taƙaitaccen gabatarwar flange da haɗin bututu ta hanyoyi da yawa. Na f...Kara karantawa -

Yin aiki na bakin karfe flange yana buƙatar fahimta da kula da wasu matsalolin

1, Weld lahani: bakin karfe flange weld lahani ne mafi tsanani, idan shi ne don amfani da manual inji nika magani Hanyar gyara, da nika alamomi, sakamakon m surface, zai shafi bayyanar; 2, polishing da polishing passivation ba uniform: pickling passivat ...Kara karantawa -

Forgings na pickling da tsaftar fashewa

Ana amfani da jabu sosai a masana'antu, kamar jiragen sama, motoci da sauransu. Tabbas, ana kuma tsaftace jabun jabun, abubuwan da ke biyo baya shine don ba ku labarin ilimin pickling da harbe-harbe. Ɗauka da tsaftacewa na jabu: Cire ƙarfe oxides ta hanyar sinadarai ...Kara karantawa -

Menene bambanci tsakanin welded flanges, lebur welded flanges da soket welded flanges?

A cikin HG, flanges-welded, flanges-welded flanges da soket welded flanges suna da ma'auni daban-daban. Abubuwan da ake amfani da su sun bambanta, bugu da ƙari, flange-welding shine diamita bututu da kauri na bangon ƙarshen dubawa kuma iri ɗaya ne da bututun da za a yi walda, kuma bututun biyu suna welded ...Kara karantawa -

Menene halayen karfe na musamman?

Idan aka kwatanta da ƙarfe na yau da kullun, ƙarfe na musamman yana da ƙarfi da ƙarfi da ƙarfi, kaddarorin jiki, kaddarorin sinadarai, biocompatibility da aikin aiwatarwa. Amma karfe na musamman yana da wasu halaye daban-daban daga karfe na yau da kullun. Ga karfe na yau da kullun mutane da yawa sun fi fahimta, amma f...Kara karantawa -

Matsayin zaɓi na kayan da aka yi amfani da su don flange mara kyau

Non-misali flanges ne wadanda ba karfe kayan tare da refractory digiri na ba kasa da 1587 ℃. Ya kamata a karbe shi bisa ga buƙatun ƙirar samfur, kuma yakamata ya dace da ƙa'idodin kayan ƙasa na yanzu. Flanges marasa daidaituwa suna shafar jiki da na inji ...Kara karantawa -

Muhimmin rawar da kayan ƙirƙira shaft

Gear shaft forgings bisa ga siffar axis, da shaft za a iya raba crankshaft da madaidaiciya shaft biyu Categories. Dangane da ƙarfin ɗaukar hoto, ana iya ƙara raba shi zuwa: (1) Juyawa mai juyawa, lokacin aiki, yana ɗaukar lokacin lanƙwasa da juzu'i. Shi ne...Kara karantawa -

Yadda za a zabi ƙirƙira mai nauyi?

Manyan jabun jabun suna taka muhimmiyar rawa wajen aikin injiniya, don haka yadda ake sarrafa manyan jabun jabun ya zama abin da kowa ke jan hankalin kowa, sannan mu kawo muku wasu hanyoyin sarrafa manyan jabu. Nau'in zobe mai nauyi shine a mirgine da jabun zuwa siffa mai zagaye, wanda zai iya asali...Kara karantawa