1. Isothermal ƙirƙirashine kiyaye zafin billet ɗin akai-akai yayin aiwatar da tsari gabaɗaya.Isothermal ƙirƙiraana amfani da shi don cin gajiyar babban filastik na wasu karafa a yawan zafin jiki ko don samun takamaiman tsari da kaddarorin. Isothermal ƙirƙira yana buƙatar ƙirƙira da billet ɗin da za a adana su a koyaushe tare, wanda ke buƙatar tsada mai tsada kuma ana amfani da shi kawai don ƙirƙira da latsawa na musamman, kamar ƙirar superplastic.

2. Ƙirƙirazai iya canza tsarin karfe kuma inganta aikin karfe. Bayanƙirƙira mai zafiingot, asalin simintin simintin gyare-gyare na asali na sako-sako, pore, micro crack an compacted ko welded; Asalin kiristocin dendritic ya karye don sanya hatsi ya yi kyau. A lokaci guda, canza asali carbide segregation da m rarraba, sabõda haka, kungiyar ne uniform, don samun na ciki m, uniform, lafiya, mai kyau m yi, m amfani da forgings. Bayanƙirƙira mai zafinakasawa, karfe shine tsarin fibrous; Bayan nakasar ƙirƙira sanyi, lu'ulu'u na ƙarfe suna nuna tsari.

3.ƙirƙirashine a sanya karfen filastik ya kwarara kuma an sanya shi cikin siffar da ake so na workpiece. Ƙarfin ƙarfe ba ya canzawa bayan kwararar filastik ta ƙarfin waje, kuma ƙarfe koyaushe yana gudana zuwa ɓangaren mafi ƙarancin juriya. A cikin samarwa, ana sarrafa sifar aikin sau da yawa bisa ga waɗannan dokoki, kuma an gane nakasar zane mai ban haushi, reaming, lankwasawa da zane mai zurfi.

4.daƙirƙira workpiecegirman daidai yake, yana dacewa da tsarin samar da taro.Mutu ƙirƙira, extrusion, stamping da sauran aikace-aikace na mold kafa size ne daidai da barga. Ana iya amfani da injunan ƙirƙira ingantattun injunan ƙirƙira da layin samar da ƙirƙira ta atomatik don tsara ƙirar ƙira ta musamman ko samar da taro.

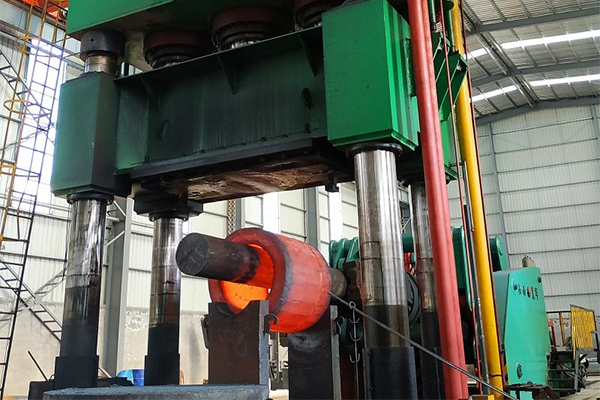

5.Tsarin samarwa naƙirƙiraya haɗa da ƙulle-ƙulle, dumama da pretreatment na ƙirƙira blan kafin kafa; Heat magani, tsaftacewa, calibration da dubawa na workpiece bayan forming. Injunan juzu'i da aka fi amfani da su suna da guduma, latsa ruwa da injin injin. Hammer mai ƙirƙira yana da babban tasiri mai saurin tasiri, wanda ke dacewa da kwararar filastik karfe, amma zai haifar da girgiza; Latsa na'ura mai aiki da karfin ruwa yana amfani da ƙirƙira ƙirƙira, yana da fa'ida ga ƙirƙira ta hanyar ƙarfe da ƙungiyar haɓakawa, aikin yana da ƙarfi, amma yawan aiki yana da ƙasa; Latsa injin yana da kafaffen bugun jini, wanda ke da sauƙin gane injina da sarrafa kansa.

A nan gaba, dafasahar jabuzai inganta ingancin ciki nasassa masu ƙirƙira, haɓaka daidaitoƙirƙirada madaidaicin fasaha na stamping, haɓakakayan aikin ƙirƙirakumaƙirƙira samarwalayi tare da mafi girma yawan aiki da digiri na atomatik, haɓakam ƙirƙirakafa tsarin, da kuma inganta sabonkayan ƙirƙirakumasarrafa jabuhanyoyin. Don inganta ingancin ciki naƙirƙira, shi ne yafi inganta su inji Properties (ƙarfi, plasticity, tauri, gajiya ƙarfi) da kuma AMINCI. Wannan yana buƙatar mafi kyawun aikace-aikacen ka'idar lalata filastik karfe; Aiwatar da ingantattun kayan inganci; Gyara pre-zurfafa dumama da ƙirƙira maganin zafi; Karin tsauraran gwaje-gwaje marasa lalacewa na jabu.

Lokacin aikawa: Janairu-25-2021