Thekayan ƙirƙiraakasari sun hada da karfen carbon da gami da karfe, sai kuma aluminium, da magnesium, da tagulla, da titanium da sauran kayan aikinsu. Asalin yanayin kayan shine mashaya, ingot, foda na ƙarfe da ƙarfe na ruwa. Matsakaicin yanki na giciye na ƙarfe kafin da bayan nakasawa ana kiransa daƙirƙira rabo. Madaidaicin zaɓi naƙirƙira rabo, Madaidaicin zafin jiki na dumama da lokacin riƙewa, madaidaicin zafin ƙirƙira na farko da zafin ƙirƙira na ƙarshe, madaidaicin adadin lalacewa da saurin nakasawa suna da babban tasiri akan haɓaka ingancin samfur da rage farashi.

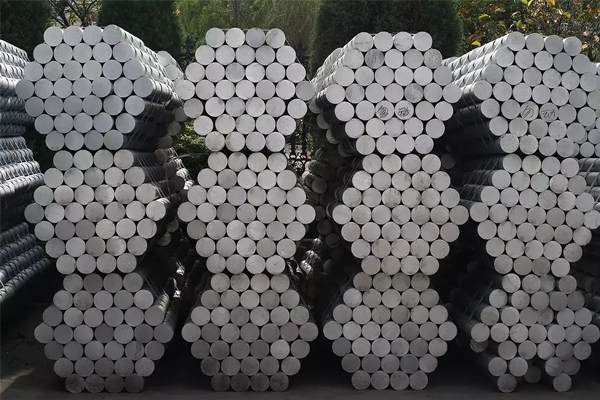

Gabaɗaya ƙarami kumamatsakaici forgingssanduna ne zagaye ko murabba'ai kamar billet. A sanduna da uniform tsarin hatsi da kyau inji Properties, m siffar da girman, mai kyau surface quality, dace da taro samar. Idan dai ana sarrafa yanayin zafi mai zafi da nakasawa, yana da kyauƙirƙiraza a iya ƙirƙira ba tare dababban ƙirƙiranakasawa.

Ana amfani da Ingot don kawaimanyan ƙirƙira. Ingot shine tsarin simintin simintin gyare-gyare tare da manyan lu'ulu'u na ginshiƙai da wuraren kwance. Sabili da haka, dole ne a karya lu'ulu'u na columnar zuwa cikin hatsi mai kyau ta hanyar manyan lahani na filastik, kuma rashin daidaituwa na iya samun kyakkyawan tsari na karfe da kaddarorin inji.

Za a iya yin ƙirƙira foda daga pre- made powder metallurgy preforms bayan dannawa da harbe-harbe a ƙarƙashin yanayin zafi tamutu ƙirƙiraba tare da tafawa ba.Forgingsfoda yana kusa da yawa na talakawamutu forgings, tare da kyawawan kayan aikin injiniya da madaidaicin madaidaici, wanda zai iya rage yankan na gaba. Forgings foda tare da tsari na ciki iri ɗaya kuma babu rarrabuwa da za a iya amfani da shi don kera ƙananan gears da sauran kayan aiki. Duk da haka, farashin foda yana da yawa fiye da na mashaya na yau da kullum, don haka aikace-aikacensa a cikin samarwa yana iyakance. ,

Siffar da ake so da kaddarorinmutu forgingsza a iya samu ta hanyar yin amfani da matsa lamba a tsaye ga ƙarfe na ruwa yana zubowa a cikin ɗakin mutu don sanya shi ƙarfafa, crystallize, kwarara, nakasar filastik da tsari a ƙarƙashin aikin matsa lamba. Ƙarfe mai ƙirƙira ƙirƙira hanya ce ta samar da ita tsakanin simintin gyare-gyare da mutun ƙirƙira, musamman dacewa da ɓangarorin ɓangarorin sirara waɗanda ke da wahalar ƙirƙirar ta talakawa.mutu ƙirƙira.

Ƙirƙirakayan ban da kayan da aka saba da su, kamar nau'ikan nau'ikan carbon karfe da gami da ƙarfe, gami da aluminum, magnesium, jan ƙarfe, titanium da gami, babban zafin jiki ƙarfe tushe gami, nickel base superalloy, nakasar superalloy na tushen cobalt na gami kuma yana amfani da hanyar ƙirƙira ko mirgina, kawai gami saboda yankin filastik ɗin sa yana da kunkuntar, don hakaƙirƙiraWahala za ta kasance in mun gwada da girma, Daban-daban kayan zafi zafin jiki, buɗaɗɗen zafin jiki na ƙirƙira da zafin ƙirƙira na ƙarshe suna da takamaiman buƙatu.

Lokacin aikawa: Maris 14-2022