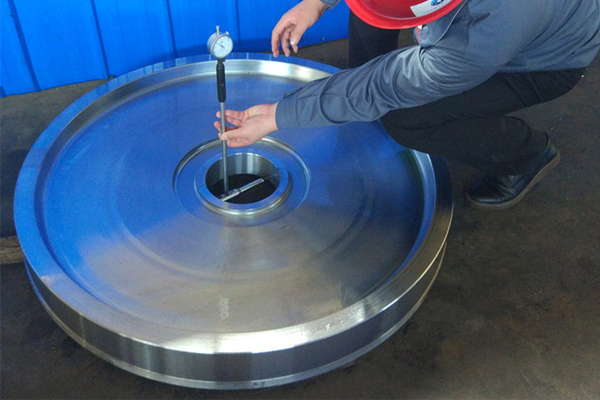

Duban ingancin bayyanar gabaɗaya dubawa ce mara lalacewa, yawanci tare da tsiraicin ido ko ƙaramin gilashin ƙara girman, idan ya cancanta, kuma a yi amfani da hanyar dubawa mara lalacewa.

Hanyoyin dubawa na ingancin ciki naƙirƙira mai nauyiza a iya taƙaita shi kamar: binciken ƙungiyar macroscopic, duban ƙungiyoyin microscopic, duba kaddarorin inji, nazarin abubuwan sinadaran da gwajin marasa lalacewa.

Macroscopic microstructure gwajin wani nau'i ne na gwaji don dubawa da kuma nazarin halayen ƙananan ƙananan ƙananan ƙarfiƙirƙirata hanyar gani ko ƙaramar gilashin ƙara girma. Hanyoyin da aka saba amfani da su don duba tsarin macroscopic naƙirƙiraHanyar lalata ce mara ƙarfi (ciki har da lalatawar thermal, lalatawar sanyi da hanyar lalatawar electrolytic), gwajin karyewa da hanyar buga sulfur.

Ka'idar duba tsarin ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun tsarin shine a yi amfani da microscope mai haske don bincika ƙananan ƙirarƙirƙirana abubuwa daban-daban. Abubuwan dubawa gabaɗaya sun haɗa da girman hatsi na ciki, ko girman hatsi a ƙayyadadden zafin jiki, watau ainihin girman hatsi, haɗawar da ba ta ƙarfe ba, microstructure kamar Layer decarburization, inhomogeneity na eutectic carbide, overheat, overburn da sauran microstructure da ake buƙata, da sauransu.

Kaddarorin injina da aikin binciken aikin shine sun kasance maganin zafi na ƙarshe naƙirƙirada ɓangarorin gwaji da aka sarrafa su cikin ƙayyadaddun samfurin bayan amfani da injin gwajin ƙarfi, injin gwajin tasiri, injin gwajin juriya, injin gwajin gajiya, gwajin ƙarfi da sauran kayan aikin don tantance kaddarorin injin da aiwatar da ƙimar aikin.

Gwajin abubuwan da ke tattare da sinadarai gabaɗaya shi ne yin amfani da nazarin sinadarai ko nazari na ƙirƙira bincike da gwaji, tare da haɓakar kimiyya da fasaha, duka nazarin sinadarai da nazarce-nazarcen nazarinsa na nufin sun sami ci gaba. Don bincike na gani, yanzu ba kawai ta amfani da hanya mai ban sha'awa da hanyar spectroscopic don aiwatar da bincike na ɓangaren ba, fitowar na'urar spectrometer ba kawai bincike mai sauri ba, amma kuma yana haɓaka daidaito sosai, kuma fitowar ta plasma photoelectric spectrometer ya inganta daidaiton bincike, daidaiton bincikensa na iya isa matakin 10-6, wannan hanyar tana da tasiri sosai, kamar yadda cutar S, kamar yadda S. forgings superalloy.

A sama, Hanyar gwaji, macroscopic kungiyar, da abun da ke ciki da microstructure gwajin ko aiki ko hanya, duk suna cikin hanyar gwaji mai lalacewa, don wasu nau'ikan ƙirƙira na hanyoyin lalata ba za su iya daidaitawa gaba ɗaya ga abin da ake buƙata na duba ingancin ba, a gefe guda, wannan saboda ba tattalin arziƙin ba ne, a gefe guda kuma ya fi dacewa don guje wa gwajin ɓarna ɗaya. Haɓaka fasahar NDT tana ba da ƙarin ci gaba da ingantattun hanyoyi donƙirƙiraingancin dubawa.

Hanyoyin gwaji marasa lalacewa don ƙirƙira ingancin dubawa gabaɗaya sune: Hanyar duban foda, hanyar bincikar shigar ciki, hanyar binciken eddy na yanzu, hanyar binciken ultrasonic.

Ana amfani da hanyar duba ƙwayoyin magnetic ko'ina don bincika saman ko kusa da lahani na ƙarfe na ƙarfe ko gamiƙirƙira, irin su fasa, wrinkles, farin spots, wadanda ba karfe inclusions, delamination, folding, carbide ko ferritic makada, da dai sauransu Wannan hanya ne kawai dace da dubawa na ferromagneticƙirƙira, amma ba don ƙirƙira da aka yi da ƙarfe austenitic ba.

Hanyar dubawa mai shiga tsakani ba zata iya kawai bincika ƙirƙira kayan magnetic ba, har ma bincika lahanin saman kayan da ba ferromagnetic ba.ƙirƙira, irin su fasa, sako-sako, nadawa, da dai sauransu. Gabaɗaya, ana amfani da shi ne kawai don bincika lahani na abubuwan da ba na ferromagnetic ba, kuma ba za a iya samun ɓoyayyun lahani a ƙasan farfajiyar ba. Ana amfani da gwajin Eddy don bincika saman ko kusa da lahani na kayan aiki.

Ultrasonic dubawa Hanyar da ake amfani da su duba ciki lahani na forgings kamar shrinkage rami, farin tabo, core crack, slag hada, da dai sauransu Ko da yake wannan hanya ne dace, azumi da kuma tattali, yana da wuya a daidai ƙayyade yanayin lahani.

Lokacin aikawa: Nuwamba-17-2021