Kayan aiki da kayan aiki da ake amfani da su don ƙirƙira kyauta suna da sauƙi, duniya da ƙananan farashi. Idan aka kwatanta da jefar da babu komai.kyauta ƙirƙirayana kawar da kogin shrinkage, raguwar porosity, porosity da sauran lahani, don haka blank yana da mafi girman kayan aikin injiniya.Forgingssuna da sauƙi a cikin siffar da sassauƙa a cikin aiki. Saboda haka, yana da mahimmanci musamman wajen kera manyan injuna da sassa masu mahimmanci.

Filin aikace-aikace

Ƙirƙirar ƙirƙiraana sarrafa su ta hanyar aikin hannu na siffar da girman girmanƙirƙira, haka daƙirƙira daidaitoyana da ƙasa, alawus ɗin sarrafawa yana da girma, ƙarfin aiki yana da girma, yawan aiki ba shi da yawa, don haka ana amfani dashi galibi a cikin guda ɗaya, ƙaramin tsari.

1) Girman billet da matsakaicin girman dole ne su dace da wuraren aiki na kowane tsari, kamar ma'aunin tsayi-diamita (H/D) na abu kafin tashin hankali shine 2-2.5, da ingantaccen bayanan canji na sashe lokacin zana.

2) wajibi ne don kimanta canjin girman blank a cikinhanyoyin ƙirƙira,alal misali, tsayin da ba komai yana raguwa lokacin bugawa, gabaɗaya sau 1.1 na tsayin ƙirƙira; Lokacin da core shaft reaming tsawo ya karu.

3) shigar da sashe, dole ne a tabbatar da cewa kowane ɓangare na ƙirƙira yana da isasshen girma, kamar a cikin shaft ɗin mataki, crankshaft ko gear boss billet, yayi kyakkyawan aiki na rarraba ƙarar kowane sashi.

4) Lokacinƙirƙiratare da gobara da yawa, dole ne a biya hankali ga yiwuwar dumama kowace wuta a tsakiya. Idan daƙirƙiraana ja da tsayi da yawa a farkon, girman tanderun bai isa a saka a cikin dogon forgings a lokacin dumama na biyu ba. Don tabbatar da girma da ingancin jabun, ya kamata a ba da kulawa ta musamman ga gurɓacewar wuta bayan Z da kuma kula da yanayin zafin ƙirƙira ta farko da ta ƙarshe bayan Z.

5) Wajibi ne a tabbatar da cewa an sami isassun alawus na gyaran fuska bayan kammala Z, kuma a kula da:

(1) Domin a yayin da ake matse kafada, kora, da naushi da dai sauransu, akwai wani lamari na yin zane da raguwa a kan abin da ba komai ba, wanda dole ne a bar alawus din sutura a tsakiya;

(2) Tsawon dajishaft forgings(kamar crankshafts, da dai sauransu) daƙirƙiratare da concave tubalan, saboda tsayin su ba zai iya zama da damuwa sake, dole ne a kiyasta cewa girman da tsawon shugabanci za a dan kadan mika a cikin miya da kai ga fita-na-haƙuri.

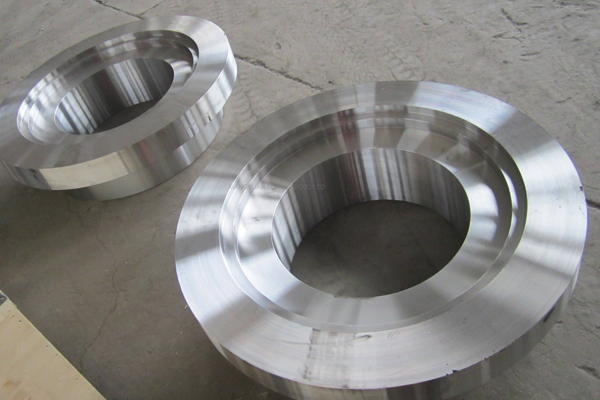

Ƙirƙira

6) Lokacin zabar kayan aiki, yara suyi amfani da kayan aikin gabaɗaya. Lokacin da samfurin samar ya yi girma, ana iya yin kayan aiki na musamman ko ƙirar taya don inganta inganci da fitarwa na ƙirƙira.

7) Dangane da girman da ingancin babur, zaɓi kayan aikin da ke cikin bitar.

Lokacin aikawa: Dec-15-2021