Good quality China Forging Round Bar - Forged Cylinders – DHDZ

Good quality China Forging Round Bar - Forged Cylinders – DHDZ Detail:

Open Die Forgings Manufacturer In China

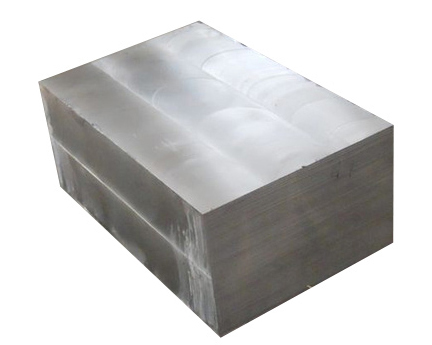

FORGED CYLINDER

| Max. O.D. | Max. Length | Max. Weight |

| 4000mm | 10 000mm | 30 Tons |

DHDZ manufactures seamless forged, heavy wall hollow cylinders and sleeves in a variety of customized configurations as per customer requirements. Seamless forged hollows are ideal for high-stress applications and harsh environments due to their durability, strength and corrosion resistance. Hollows can be produced not only in a straight cylindrical shape, but with unlimited variations of O.D.s and I.D.s, including tapers.

Additionally DHDZ offers all downstream processing including heat treatment, machining and mechanical and non-destructive testing, upon request. Contact us today with your exact specifications, our team will work with you to capitalize on our capabilities to minimize material waste and reduce process inefficiencies.

Common used material: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV |EN 1.4201 |42CrMo4

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., as an ISO registered certified forging manufacturer, guarantee that the forgings and/or bars are homogenous in quality and free of anomalies which are detrimental to the mechanical properties or machining properies of the material .

Case: Steel Grade AISI 4130 Alloy Steel (UNS G41300)

Physical Properties

| Properties | Metric | Mperial |

| Density | 7.85 g/cm3 | 0.284 lb/in³ |

| Melting point | 1432°C | 2610°F |

AISI 4130 Alloy Steel Relevant Specifications and Equivalents

|

AISI 4130 |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

Cu |

Mo |

|

0.280 – 0.330 |

0.40 – 0.60 |

0.15 – 0.30 |

0.030 max |

0.040 max |

0.80-1.10 |

0.15-0.25 |

0.25 max |

0.35 max |

0.15-0.25 |

|

ASTM A29/A29M |

DIN17350 |

JIS G4404 |

GB/T 1229 |

ISO 683/18 |

|

AISI 4130/ G41300 |

1.7218/25CrMo4 |

SMN 420 |

25CrMo4 |

25CrMo4 |

Applications

Some typical application areas for AISI 4130:

Oil and gas industries – as forged valve bodies and pumps

Commercial aircraft, aircraft engine mounts

Military aircraft

Automotive

Machine tools

Hydraulic tools

Auto racing

Aerospace

Agricultural and defense industries etc.

AISI 4130 Forged Cylinder , Low alloy Steel forgings for oil and gas industries.

Size: φ774.8 0xφ317.0XH825.5mm

Fabrication and Heat Treatment

Machinability - AISI 4130 steel can be easily machined using conventional methods. However, machining becomes difficult when the hardness of the steel is increased.

Forming of AISI 4130 steel can be performed in the annealed condition.

● Welding of AISI 4130 steel can be performed by all commercial methods.

● Heat Treatment - AISI 4130 steel is heated at 871°C (1600°F) and then quenched in oil. This steel is usually heat-treated at temperatures ranging from 899 to 927°C (1650 to 1700°F).

● Forging of AISI 4130 steel can be performed at 954 to 1204°C (1750 to 2200°F).

● Hot working of AISI 4130 steel can be done at 816 to 1093°C (1500 to 2000°F).

● AISI 4130 steel can be cold worked using conventional methods.

● AISI 4130 steel can be annealed at 843°C (1550°F) followed by air cooling at 482°C (900°F).

● Tempering of AISI 4130 steel can be performed at 399 to 566°C (750 to 1050°F), depending on the desired strength level.

● Hardening of AISI 4130 steel can be done with cold working or heat treatment.

Some of the major applications of AISI 4130 alloy steel are in aircraft engine mounts and welded tubing.

Forging (Hot Work ) Practice , Heat Treatment Procedure

|

Forging |

1093-1205℃ |

|

Annealing |

778-843℃ furnace cool |

|

Tempering |

399-649℃ |

|

Normalizing |

871-898℃ air cool |

|

Austenize |

815-843℃ water quench |

|

Stress Relieve |

552-663℃ |

|

Quenching |

552-663℃ |

|

Rm - Tensile strength (MPa) (Q +T) |

≥930 |

|

Rp0.2 0.2% proof strength (MPa) (Q +T) |

≥785 |

|

KV - Impact energy (J) (Q +T) |

+20° |

|

A - Min. elongation at fracture (%)(Q +T) |

≥12 |

|

Z - Reduction in cross section on fracture (%)(N+Q +T) |

≥50 |

|

Brinell hardness (HBW): (Q +T) |

≤229HB |

ADDITIONAL INFORMATION

REQUEST A QUOTE TODAY

OR CALL: 86-21-52859349

4130

4130

New-4130-Alloy-Steel

New-4130-Alloy-Steel

Product detail pictures:

Related Product Guide:

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Good quality China Forging Round Bar - Forged Cylinders – DHDZ , The product will supply to all over the world, such as: French, Slovak Republic, Senegal, With many years good service and development, we have a qualified international trade sales team. Our goods have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.