factory Outlets for Large Diameter Flanges - Forged Discs – DHDZ

factory Outlets for Large Diameter Flanges - Forged Discs – DHDZ Detail:

Open Die Forgings Manufacturer In China

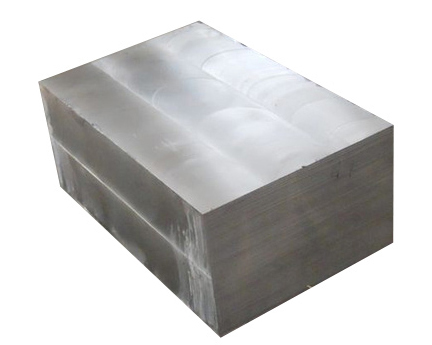

Forged Disc

Gear blanks, flanges, end caps, pressure vessel components, valve components, valve bodies, and piping applications. Forged disks are superior in quality to disks cut from plate or bar due to all sides of the disk having forging reduction further refining the grain structure and improving the materials impact strength and fatigue life. Furthermore forged disks can be forged with grain flow to best suit the final parts applications such as radial or tangential grain flow which will help improve the mechanical properties of the material.

Common used material: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV

FORGED DISC

Large press forged blocks up to 1500mm x 1500mm section with variable length.

Block forging tolerance typically -0/+3mm up to +10mm dependent on size.

●All Metals has the forging capabilities to produce bars from the following alloy types:

● Alloy steel

● Carbon steel

●Stainless steel

FORGED DISCS CAPABILITIES

Material

MAX DIAMETER

MAX WEIGHT

Carbon, Alloy Steel

3500mm

20000 kgs

Stainless Steel

3500mm

18000 kgs

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD. , as an ISO registered certified forging manufacturer, guarantee that the forgings and/or bars are homogenous in quality and free of anomalies which are detrimental to the mechanical properties or machining properies of the material.

Case:

Steel Grade SA 266 Gr 2

|

Chemical composition % of steel SA 266 Gr 2 |

||||

|

C |

Si |

Mn |

P |

S |

|

Max 0.3 |

0.15 – 0.35 |

0.8- 1.35 |

max 0.025 |

max 0.015 |

Applications

Gear blanks, flanges, end caps, pressure vessel components, valve components, valve bodies, and piping applications

Delivery form

Forged disc, Forged Disk

SA 266 Gr 4 Forged disc, Carbon steel forgings for pressure vessels

Size: φ1300 x thk 180mm

Forging (Hot Work ) Practice, Heat Treatment Procedure

|

Forging |

1093-1205℃ |

|

Annealing |

778-843℃ furnace cool |

|

Tempering |

399-649℃ |

|

Normalizing |

871-898℃ air cool |

|

Austenize |

815-843℃ water quench |

|

Stress Relieve |

552-663℃ |

|

Quenching |

552-663℃ |

| Rm - Tensile strength (MPa) (N) |

530 |

| Rp0.2 0.2% proof strength (MPa) (N) |

320 |

| A - Min. elongation at fracture (%) (N) |

31 |

| Z - Reduction in cross section on fracture (%) (N) |

52 |

| Brinell hardness (HBW): | 167 |

ADDITIONAL INFORMATION

REQUEST A QUOTE TODAY

OR CALL: 86-21-52859349

Product detail pictures:

Related Product Guide:

We've got a really efficient group to deal with inquiries from prospects. Our purpose is "100% customer fulfillment by our product excellent, price & our group service" and enjoy a superb track record amid clientele. With many factories, we can easily deliver a wide selection of factory Outlets for Large Diameter Flanges - Forged Discs – DHDZ , The product will supply to all over the world, such as: Kuala Lumpur, Vietnam, Germany, because of our company has been persisting in the management idea of "Survival by Quality, Development by Service, Benefit by Reputation" . We fully realize the good credit standing, the high quality products, the reasonable price and the professional services are the reason that the customers choose us to be their long-term business partner.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!